Hyperautomation integrates AI, machine learning, and robotic process automation to streamline manufacturing workflows and reduce human intervention. Advanced process control utilizes real-time data, predictive analytics, and model-based control to optimize production efficiency and maintain product quality. Discover how these technologies revolutionize manufacturing by enhancing precision and operational speed.

Why it is important

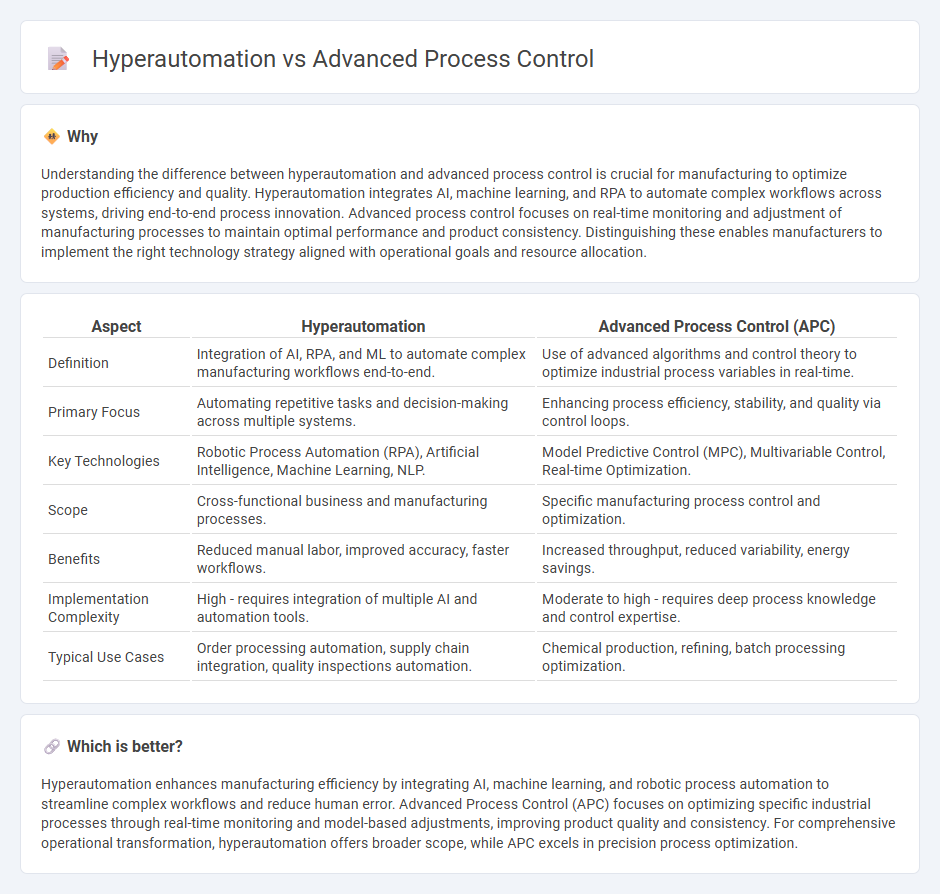

Understanding the difference between hyperautomation and advanced process control is crucial for manufacturing to optimize production efficiency and quality. Hyperautomation integrates AI, machine learning, and RPA to automate complex workflows across systems, driving end-to-end process innovation. Advanced process control focuses on real-time monitoring and adjustment of manufacturing processes to maintain optimal performance and product consistency. Distinguishing these enables manufacturers to implement the right technology strategy aligned with operational goals and resource allocation.

Comparison Table

| Aspect | Hyperautomation | Advanced Process Control (APC) |

|---|---|---|

| Definition | Integration of AI, RPA, and ML to automate complex manufacturing workflows end-to-end. | Use of advanced algorithms and control theory to optimize industrial process variables in real-time. |

| Primary Focus | Automating repetitive tasks and decision-making across multiple systems. | Enhancing process efficiency, stability, and quality via control loops. |

| Key Technologies | Robotic Process Automation (RPA), Artificial Intelligence, Machine Learning, NLP. | Model Predictive Control (MPC), Multivariable Control, Real-time Optimization. |

| Scope | Cross-functional business and manufacturing processes. | Specific manufacturing process control and optimization. |

| Benefits | Reduced manual labor, improved accuracy, faster workflows. | Increased throughput, reduced variability, energy savings. |

| Implementation Complexity | High - requires integration of multiple AI and automation tools. | Moderate to high - requires deep process knowledge and control expertise. |

| Typical Use Cases | Order processing automation, supply chain integration, quality inspections automation. | Chemical production, refining, batch processing optimization. |

Which is better?

Hyperautomation enhances manufacturing efficiency by integrating AI, machine learning, and robotic process automation to streamline complex workflows and reduce human error. Advanced Process Control (APC) focuses on optimizing specific industrial processes through real-time monitoring and model-based adjustments, improving product quality and consistency. For comprehensive operational transformation, hyperautomation offers broader scope, while APC excels in precision process optimization.

Connection

Hyperautomation integrates advanced process control (APC) by leveraging artificial intelligence and machine learning to optimize manufacturing workflows, enhancing precision and reducing variability. APC uses real-time data analytics and predictive modeling to maintain process parameters within optimal ranges, which hyperautomation expands through automated decision-making and adaptive process adjustments. Combined, these technologies drive efficiency, minimize downtime, and improve product quality across complex manufacturing systems.

Key Terms

**Advanced Process Control:**

Advanced Process Control (APC) utilizes sophisticated algorithms and real-time data to optimize industrial processes, enhancing efficiency, productivity, and product quality through precise control over variables such as temperature, pressure, and flow rates. APC integrates with Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC) to enable predictive adjustments and reduce operational variability in sectors like chemical manufacturing, oil refining, and pharmaceuticals. Explore more about how APC drives operational excellence and sustainability in complex process industries.

Model Predictive Control

Model Predictive Control (MPC) is a cornerstone of advanced process control, optimizing industrial processes by predicting future outputs and adjusting inputs within constraints for enhanced efficiency and stability. Hyperautomation extends beyond traditional control by integrating AI, machine learning, and robotic process automation to automate complex workflows and decision-making across the enterprise. Explore the unique benefits and applications of MPC within hyperautomation frameworks to understand how these technologies drive smarter, data-driven industrial innovation.

Real-time Optimization

Advanced Process Control (APC) leverages real-time data and predictive models to optimize industrial processes by minimizing variability and enhancing efficiency, whereas hyperautomation integrates multiple technologies like AI, machine learning, and robotic process automation to automate complex workflows beyond traditional control systems. In the context of real-time optimization, APC provides precise control adjustments based on live sensor inputs, while hyperautomation employs broader operational intelligence to not only optimize but also automate decision-making across enterprise systems. Explore the nuances between these transformative approaches to elevate your operational strategy.

Source and External Links

Advanced Process Control: Definition, Benefits, and Applications - Advanced Process Control (APC) uses advanced techniques like Model Predictive Control, multivariable control, and real-time data integration to optimize industrial processes beyond basic regulatory systems for improved safety, efficiency, and cost savings.

Advanced process control - Wikipedia - APC refers to a range of advanced control techniques--such as feedforward, decoupling, inferential control, and Model Predictive Control--implemented in industrial process control systems to enhance performance and economics, often layered on top of basic process controls in continuous industries like chemicals, oil refining, and pharmaceuticals.

What Is Advanced Process Control? | ARC Advisory Group - APC includes multivariable predictive control (MPC) solutions that provide closed-loop, real-time, model-based control of continuous processes, enabling online optimization and improved operational economics through accurate process modeling.

dowidth.com

dowidth.com