Adaptive machining enhances production efficiency by utilizing real-time data and sensor feedback to adjust machining parameters dynamically, resulting in higher precision and reduced waste. Flexible manufacturing systems (FMS) enable rapid switching between product types through automated equipment and programmable controls, supporting diverse production demands with minimal downtime. Explore how integrating adaptive machining and flexible manufacturing can revolutionize your manufacturing processes.

Why it is important

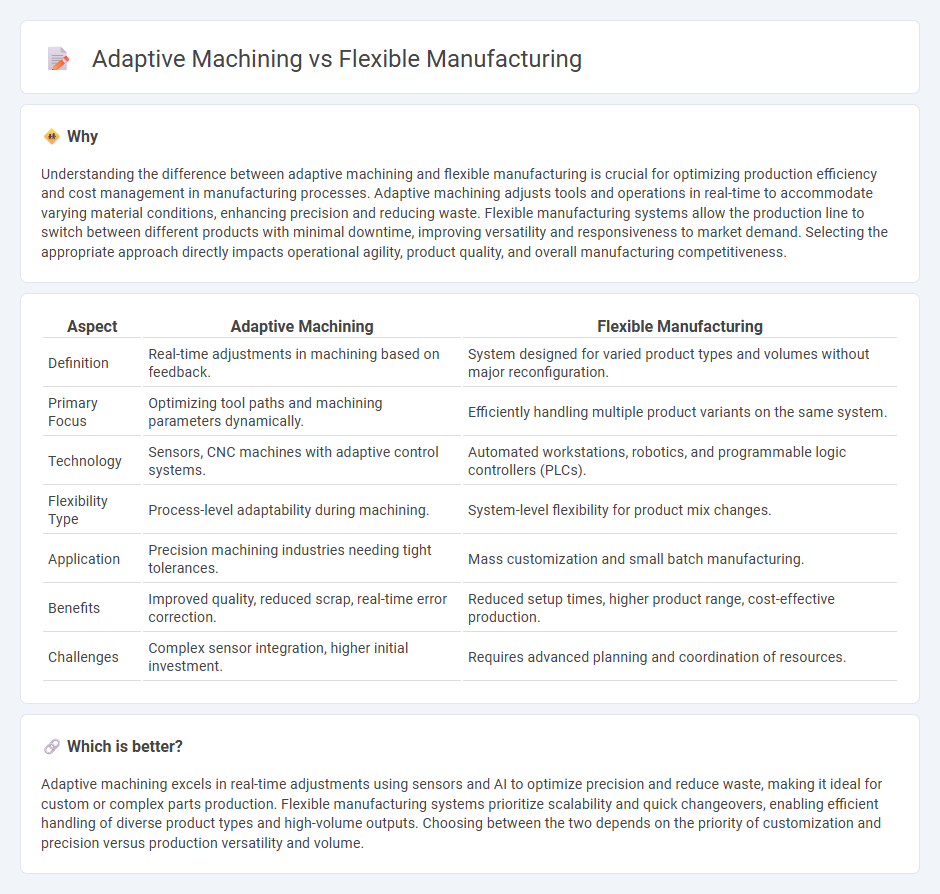

Understanding the difference between adaptive machining and flexible manufacturing is crucial for optimizing production efficiency and cost management in manufacturing processes. Adaptive machining adjusts tools and operations in real-time to accommodate varying material conditions, enhancing precision and reducing waste. Flexible manufacturing systems allow the production line to switch between different products with minimal downtime, improving versatility and responsiveness to market demand. Selecting the appropriate approach directly impacts operational agility, product quality, and overall manufacturing competitiveness.

Comparison Table

| Aspect | Adaptive Machining | Flexible Manufacturing |

|---|---|---|

| Definition | Real-time adjustments in machining based on feedback. | System designed for varied product types and volumes without major reconfiguration. |

| Primary Focus | Optimizing tool paths and machining parameters dynamically. | Efficiently handling multiple product variants on the same system. |

| Technology | Sensors, CNC machines with adaptive control systems. | Automated workstations, robotics, and programmable logic controllers (PLCs). |

| Flexibility Type | Process-level adaptability during machining. | System-level flexibility for product mix changes. |

| Application | Precision machining industries needing tight tolerances. | Mass customization and small batch manufacturing. |

| Benefits | Improved quality, reduced scrap, real-time error correction. | Reduced setup times, higher product range, cost-effective production. |

| Challenges | Complex sensor integration, higher initial investment. | Requires advanced planning and coordination of resources. |

Which is better?

Adaptive machining excels in real-time adjustments using sensors and AI to optimize precision and reduce waste, making it ideal for custom or complex parts production. Flexible manufacturing systems prioritize scalability and quick changeovers, enabling efficient handling of diverse product types and high-volume outputs. Choosing between the two depends on the priority of customization and precision versus production versatility and volume.

Connection

Adaptive machining enhances flexible manufacturing by enabling machines to automatically adjust cutting parameters in real time based on sensor feedback, ensuring consistent quality and reducing downtime. This dynamic responsiveness supports flexible manufacturing systems that require rapid changeovers and customized production runs. Integrating adaptive machining technologies optimizes efficiency and scalability within flexible manufacturing environments.

Key Terms

Automation

Flexible manufacturing systems utilize automated equipment and programmable logic controllers to handle variable production tasks, enhancing efficiency through rapid changeovers and reduced downtime. Adaptive machining employs real-time data integration and AI-driven adjustments to optimize tool paths and machining parameters, enabling precise responses to material inconsistencies and process variations. Explore the latest advancements in automation technologies to fully understand their impact on manufacturing agility.

Reconfigurability

Flexible manufacturing systems (FMS) prioritize reconfigurability by enabling rapid changes in machine setups and production processes to handle varying product types with minimal downtime. Adaptive machining incorporates real-time sensor data and AI algorithms to dynamically adjust tool paths and cutting parameters for enhanced precision and efficiency on-the-fly. Explore more on how reconfigurability drives innovation in manufacturing scalability and productivity.

Real-time feedback

Flexible manufacturing utilizes pre-programmed setups to switch between different production tasks efficiently, while adaptive machining relies on real-time feedback from sensors to modify machining parameters dynamically during operation. Adaptive machining enhances precision and reduces waste by continuously adjusting to variations in tool wear, material properties, and environmental conditions. Explore how real-time feedback integration transforms manufacturing processes for improved productivity and quality.

Source and External Links

Flexible Manufacturing Systems (FMS) | What is ... - A flexible manufacturing system is a computer-controlled production setup designed to quickly adapt to changes in product or process, enabling routing flexibility (reordering production stages) and machine flexibility (using different machines for the same task).

Flexible manufacturing system - FMS is a manufacturing system with built-in flexibility to react to predicted or unpredicted changes, typically featuring automated work machines, optimized material handling, and central computer control for efficient, adaptable production.

Flexible manufacturing - Flexible manufacturing combines smart robotics, software, and sensors to enable cost-effective production of low-volume, high-mix, and complex products, aiming for zero defects and minimal manual intervention during changeovers.

dowidth.com

dowidth.com