Servitization transforms traditional manufacturing by integrating services with products to enhance customer value and revenue streams, shifting focus from selling goods to delivering solutions. Lean Manufacturing emphasizes waste reduction, continuous improvement, and efficiency in production processes to maximize value and minimize costs. Explore how combining servitization with lean principles can revolutionize your manufacturing strategy.

Why it is important

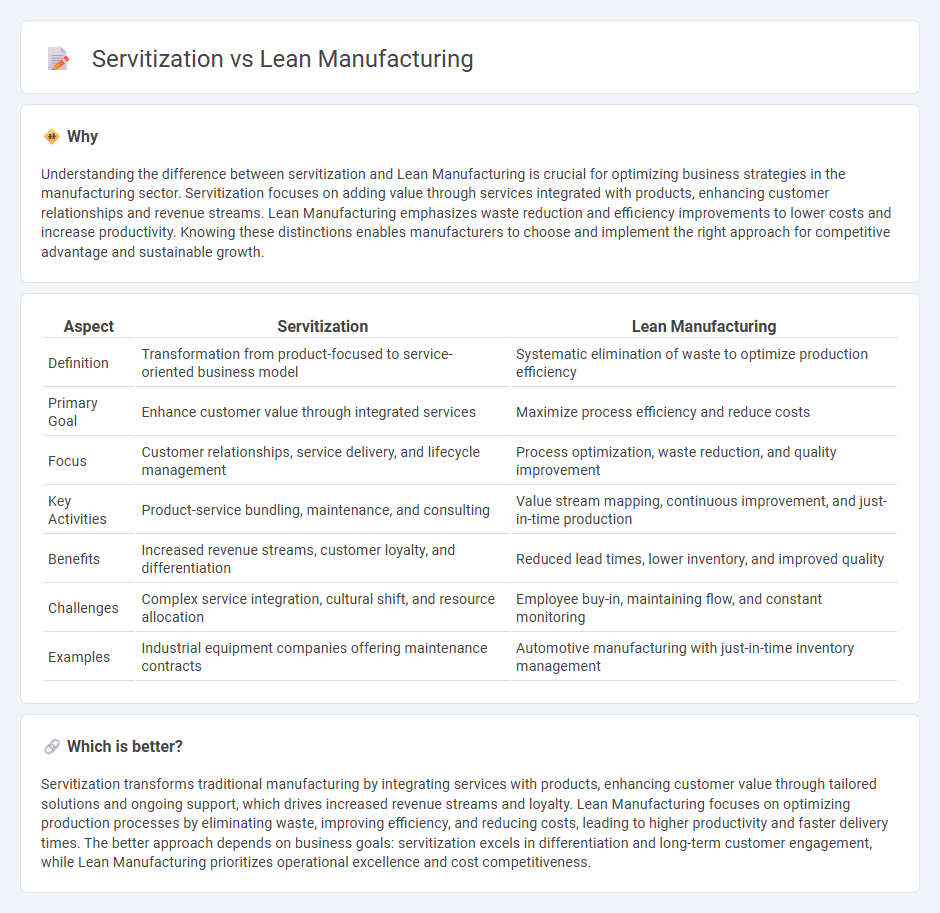

Understanding the difference between servitization and Lean Manufacturing is crucial for optimizing business strategies in the manufacturing sector. Servitization focuses on adding value through services integrated with products, enhancing customer relationships and revenue streams. Lean Manufacturing emphasizes waste reduction and efficiency improvements to lower costs and increase productivity. Knowing these distinctions enables manufacturers to choose and implement the right approach for competitive advantage and sustainable growth.

Comparison Table

| Aspect | Servitization | Lean Manufacturing |

|---|---|---|

| Definition | Transformation from product-focused to service-oriented business model | Systematic elimination of waste to optimize production efficiency |

| Primary Goal | Enhance customer value through integrated services | Maximize process efficiency and reduce costs |

| Focus | Customer relationships, service delivery, and lifecycle management | Process optimization, waste reduction, and quality improvement |

| Key Activities | Product-service bundling, maintenance, and consulting | Value stream mapping, continuous improvement, and just-in-time production |

| Benefits | Increased revenue streams, customer loyalty, and differentiation | Reduced lead times, lower inventory, and improved quality |

| Challenges | Complex service integration, cultural shift, and resource allocation | Employee buy-in, maintaining flow, and constant monitoring |

| Examples | Industrial equipment companies offering maintenance contracts | Automotive manufacturing with just-in-time inventory management |

Which is better?

Servitization transforms traditional manufacturing by integrating services with products, enhancing customer value through tailored solutions and ongoing support, which drives increased revenue streams and loyalty. Lean Manufacturing focuses on optimizing production processes by eliminating waste, improving efficiency, and reducing costs, leading to higher productivity and faster delivery times. The better approach depends on business goals: servitization excels in differentiation and long-term customer engagement, while Lean Manufacturing prioritizes operational excellence and cost competitiveness.

Connection

Servitization enhances Lean Manufacturing by shifting focus from product-centric to customer-centric value creation, enabling continuous improvement in both processes and services. Lean Manufacturing principles reduce waste and optimize efficiency, which supports the delivery of integrated product-service solutions while maintaining cost-effectiveness. This synergy drives innovation, improves customer satisfaction, and sustains competitive advantage in manufacturing industries.

Key Terms

Waste Reduction

Lean manufacturing emphasizes systematic waste reduction through techniques like value stream mapping, continuous improvement, and just-in-time production to enhance operational efficiency. Servitization reduces waste by transforming products into services, promoting resource optimization, and extending asset life cycles, which minimizes overproduction and excess inventory. Explore the key strategies behind Lean and servitization to optimize waste reduction in your business.

Value-Added Services

Lean manufacturing emphasizes waste reduction and process efficiency to optimize production value, while servitization transforms traditional product offerings into comprehensive value-added services that enhance customer experience and loyalty. Value-added services in servitization include maintenance, customization, and after-sales support, driving sustained revenue beyond initial sales. Explore how integrating lean principles with servitization strategies can boost competitive advantage and customer satisfaction in your industry.

Continuous Improvement

Lean Manufacturing emphasizes eliminating waste and optimizing production processes to achieve continuous improvement, enhancing efficiency and product quality. Servitization shifts the focus towards integrating services with products, fostering ongoing customer value and iterative enhancement of both offerings and client relationships. Discover how these strategies complement each other in driving sustained innovation and operational excellence.

Source and External Links

Lean manufacturing - Wikipedia - Lean manufacturing is a production method focused on reducing waste and minimizing non-value-adding activities within the production system, drawing heavily on the Toyota Production System and emphasizing continuous improvement and just-in-time inventory management.

What is Lean Manufacturing? | Definition from TechTarget - Lean manufacturing is a methodology that minimizes waste in manufacturing systems while maximizing productivity, with core principles such as Kaizen (continuous improvement) and practices that reduce lead times and operating costs while improving product quality.

What is Lean? Lean Manufacturing & Lean Enterprise - ASQ - Lean manufacturing is a system of management practices aimed at improving efficiency by eliminating all forms of waste (non-value-adding activities) throughout manufacturing or service operations, extending its principles across the entire value stream for optimal results.

dowidth.com

dowidth.com