Condition monitoring involves continuously tracking equipment health through sensors and data analysis to detect early signs of wear or failure. Reliability-centered maintenance (RCM) focuses on identifying critical assets and applying tailored maintenance strategies to ensure optimal performance and minimize downtime. Explore more to understand how these approaches enhance manufacturing productivity and asset longevity.

Why it is important

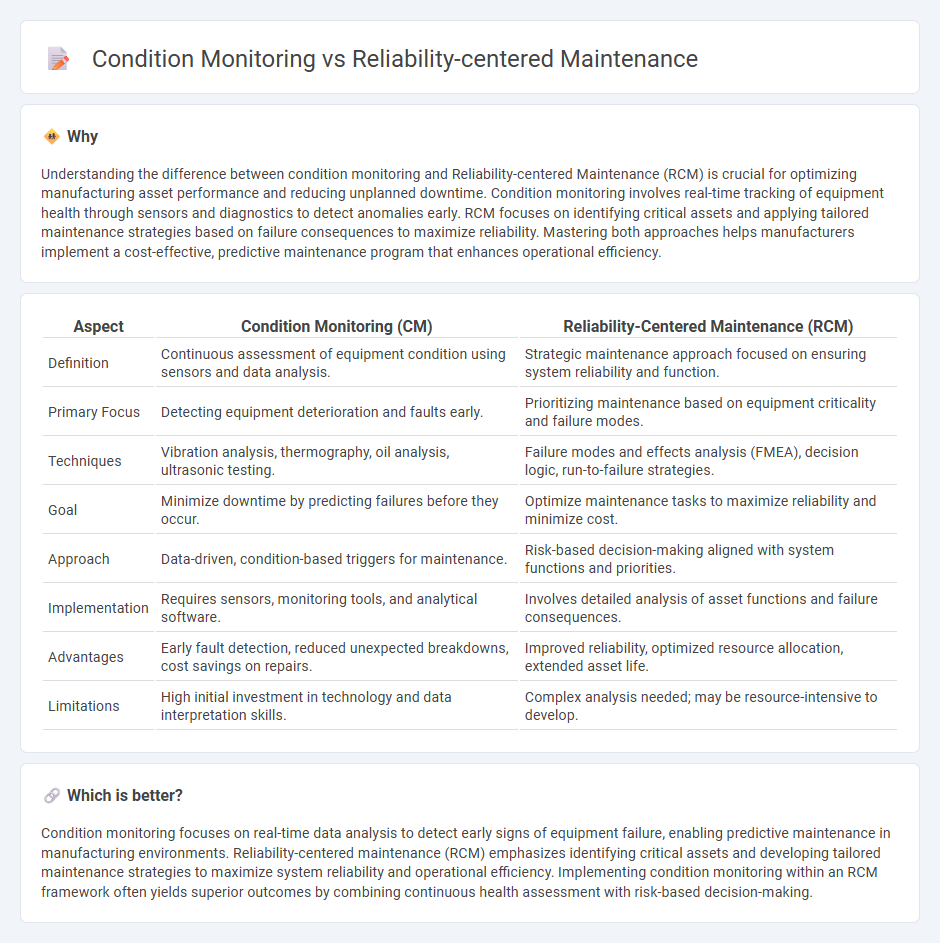

Understanding the difference between condition monitoring and Reliability-centered Maintenance (RCM) is crucial for optimizing manufacturing asset performance and reducing unplanned downtime. Condition monitoring involves real-time tracking of equipment health through sensors and diagnostics to detect anomalies early. RCM focuses on identifying critical assets and applying tailored maintenance strategies based on failure consequences to maximize reliability. Mastering both approaches helps manufacturers implement a cost-effective, predictive maintenance program that enhances operational efficiency.

Comparison Table

| Aspect | Condition Monitoring (CM) | Reliability-Centered Maintenance (RCM) |

|---|---|---|

| Definition | Continuous assessment of equipment condition using sensors and data analysis. | Strategic maintenance approach focused on ensuring system reliability and function. |

| Primary Focus | Detecting equipment deterioration and faults early. | Prioritizing maintenance based on equipment criticality and failure modes. |

| Techniques | Vibration analysis, thermography, oil analysis, ultrasonic testing. | Failure modes and effects analysis (FMEA), decision logic, run-to-failure strategies. |

| Goal | Minimize downtime by predicting failures before they occur. | Optimize maintenance tasks to maximize reliability and minimize cost. |

| Approach | Data-driven, condition-based triggers for maintenance. | Risk-based decision-making aligned with system functions and priorities. |

| Implementation | Requires sensors, monitoring tools, and analytical software. | Involves detailed analysis of asset functions and failure consequences. |

| Advantages | Early fault detection, reduced unexpected breakdowns, cost savings on repairs. | Improved reliability, optimized resource allocation, extended asset life. |

| Limitations | High initial investment in technology and data interpretation skills. | Complex analysis needed; may be resource-intensive to develop. |

Which is better?

Condition monitoring focuses on real-time data analysis to detect early signs of equipment failure, enabling predictive maintenance in manufacturing environments. Reliability-centered maintenance (RCM) emphasizes identifying critical assets and developing tailored maintenance strategies to maximize system reliability and operational efficiency. Implementing condition monitoring within an RCM framework often yields superior outcomes by combining continuous health assessment with risk-based decision-making.

Connection

Condition monitoring collects real-time data on equipment performance to detect early signs of wear or failure. Reliability-centered maintenance (RCM) uses this data to prioritize maintenance tasks based on the criticality and reliability of assets. Integrating condition monitoring with RCM enhances predictive maintenance, reduces downtime, and optimizes asset lifespan in manufacturing operations.

Key Terms

Failure Modes and Effects Analysis (FMEA)

Reliability-centered maintenance (RCM) optimizes asset performance by prioritizing failure modes based on Failure Modes and Effects Analysis (FMEA), enhancing maintenance strategies to prevent critical failures. Condition monitoring continuously tracks equipment health using real-time data to detect anomalies before failure occurs, supporting predictive maintenance frameworks. Explore in-depth comparisons and practical applications of FMEA within RCM and condition monitoring to boost operational reliability and maintenance efficiency.

Predictive Maintenance (PdM)

Reliability-centered maintenance (RCM) prioritizes asset function and failure consequences to develop tailored maintenance strategies, while condition monitoring (CM) relies on real-time data to track equipment health and predict failures. Predictive Maintenance (PdM) integrates CM technologies like vibration analysis, thermography, and ultrasonic testing within the RCM framework to optimize intervention timing and minimize downtime. Explore advanced PdM methodologies to enhance your asset management and operational efficiency.

Real-time Sensor Data

Real-time sensor data enhances reliability-centered maintenance (RCM) by providing continuous, precise insights into equipment health, enabling predictive interventions that prevent failures and reduce downtime. Condition monitoring relies on this sensor data to detect anomalies and trends, facilitating timely maintenance decisions based on actual operating conditions rather than fixed schedules. Explore how integrating real-time sensor data with RCM strategies revolutionizes asset management and operational efficiency.

Source and External Links

Reliability-Centered Maintenance (RCM) | WBDG - RCM is an optimized mix of reactive, time-based, condition-based, and proactive maintenance practices aimed at maximizing reliability and minimizing life-cycle costs by addressing system functions, failure modes, and consequences critically.

Reliability-Centered Maintenance: What It Is & How It Maximizes ... - RCM is a corporate-level preventative strategy that optimizes maintenance by identifying failure modes and prioritizing cost-effective maintenance to enhance reliability and reduce downtime.

Reliability Centered Maintenance (RCM) - Inspectioneering - RCM involves decision, analysis, and feedback phases to target critical equipment, identify root causes of failure, and continuously improve maintenance efficiency, safety, and cost-effectiveness.

dowidth.com

dowidth.com