Smart factories integrate advanced technologies like IoT, AI, and robotics to optimize production efficiency and ensure real-time data-driven decision-making. Lights-out manufacturing automates the production process to operate without human intervention, enhancing precision and continuous operation. Explore more about how these innovations are transforming manufacturing dynamics.

Why it is important

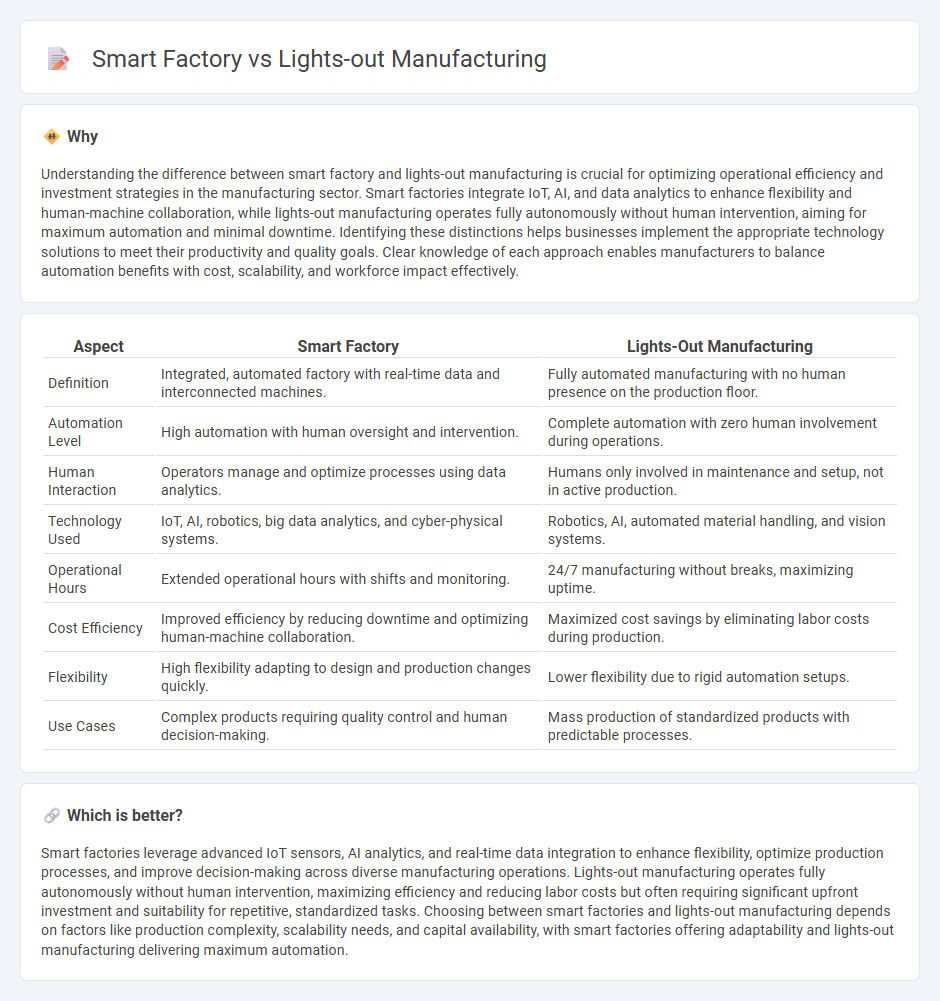

Understanding the difference between smart factory and lights-out manufacturing is crucial for optimizing operational efficiency and investment strategies in the manufacturing sector. Smart factories integrate IoT, AI, and data analytics to enhance flexibility and human-machine collaboration, while lights-out manufacturing operates fully autonomously without human intervention, aiming for maximum automation and minimal downtime. Identifying these distinctions helps businesses implement the appropriate technology solutions to meet their productivity and quality goals. Clear knowledge of each approach enables manufacturers to balance automation benefits with cost, scalability, and workforce impact effectively.

Comparison Table

| Aspect | Smart Factory | Lights-Out Manufacturing |

|---|---|---|

| Definition | Integrated, automated factory with real-time data and interconnected machines. | Fully automated manufacturing with no human presence on the production floor. |

| Automation Level | High automation with human oversight and intervention. | Complete automation with zero human involvement during operations. |

| Human Interaction | Operators manage and optimize processes using data analytics. | Humans only involved in maintenance and setup, not in active production. |

| Technology Used | IoT, AI, robotics, big data analytics, and cyber-physical systems. | Robotics, AI, automated material handling, and vision systems. |

| Operational Hours | Extended operational hours with shifts and monitoring. | 24/7 manufacturing without breaks, maximizing uptime. |

| Cost Efficiency | Improved efficiency by reducing downtime and optimizing human-machine collaboration. | Maximized cost savings by eliminating labor costs during production. |

| Flexibility | High flexibility adapting to design and production changes quickly. | Lower flexibility due to rigid automation setups. |

| Use Cases | Complex products requiring quality control and human decision-making. | Mass production of standardized products with predictable processes. |

Which is better?

Smart factories leverage advanced IoT sensors, AI analytics, and real-time data integration to enhance flexibility, optimize production processes, and improve decision-making across diverse manufacturing operations. Lights-out manufacturing operates fully autonomously without human intervention, maximizing efficiency and reducing labor costs but often requiring significant upfront investment and suitability for repetitive, standardized tasks. Choosing between smart factories and lights-out manufacturing depends on factors like production complexity, scalability needs, and capital availability, with smart factories offering adaptability and lights-out manufacturing delivering maximum automation.

Connection

Smart factories employ advanced IoT sensors, robotics, and AI-driven automation to optimize production processes, creating an environment conducive to lights-out manufacturing. Lights-out manufacturing refers to fully automated factories that operate without human intervention, achievable only through the integration of intelligent systems found in smart factories. This synergy enhances operational efficiency, reduces labor costs, and increases production accuracy in modern manufacturing.

Key Terms

Automation

Lights-out manufacturing employs fully automated production processes that operate without human intervention, maximizing efficiency and minimizing labor costs. Smart factories integrate advanced automation with IoT, AI, and real-time data analytics to optimize production flexibility and predictive maintenance. Explore the key differences and benefits of automation in both approaches to enhance your manufacturing strategy.

IoT (Internet of Things)

Lights-out manufacturing operates with minimal or no human intervention, relying heavily on automated machinery and IoT sensors to monitor production processes and ensure continuous operation. Smart factories integrate IoT devices to connect machines, systems, and humans, facilitating real-time data analytics, predictive maintenance, and adaptive manufacturing workflows. Explore the transformative impact of IoT on both lights-out manufacturing and smart factory models to understand their operational advantages.

Autonomous Operations

Lights-out manufacturing eliminates human presence on the production floor by utilizing fully automated systems capable of operating without manual intervention. Smart factories integrate IoT, AI, and data analytics to enable adaptive, real-time decision-making and autonomous operations that enhance efficiency and reduce downtime. Explore how autonomous operations transform manufacturing processes by blending automation with intelligent systems.

Source and External Links

Lights-out Factory - Describes a manufacturing setup where production operates with minimal human intervention, utilizing advanced automation and software to manage processes.

Lights Out Manufacturing - Explains how fully automated technology allows production factories to run with little or no human intervention.

Lights Out Dark Manufacturing - Discusses the concept of fully automated production that doesn't require human presence, using advanced technologies like robotics and AI.

dowidth.com

dowidth.com