Industrial metaverse integrates virtual reality and digital twin technologies to create immersive simulations of manufacturing environments, enhancing collaboration and real-time decision-making. Manufacturing Execution Systems (MES) focus on monitoring and controlling production processes to improve efficiency, quality, and traceability on the factory floor. Explore how the industrial metaverse complements MES by transforming operational data into interactive, actionable insights.

Why it is important

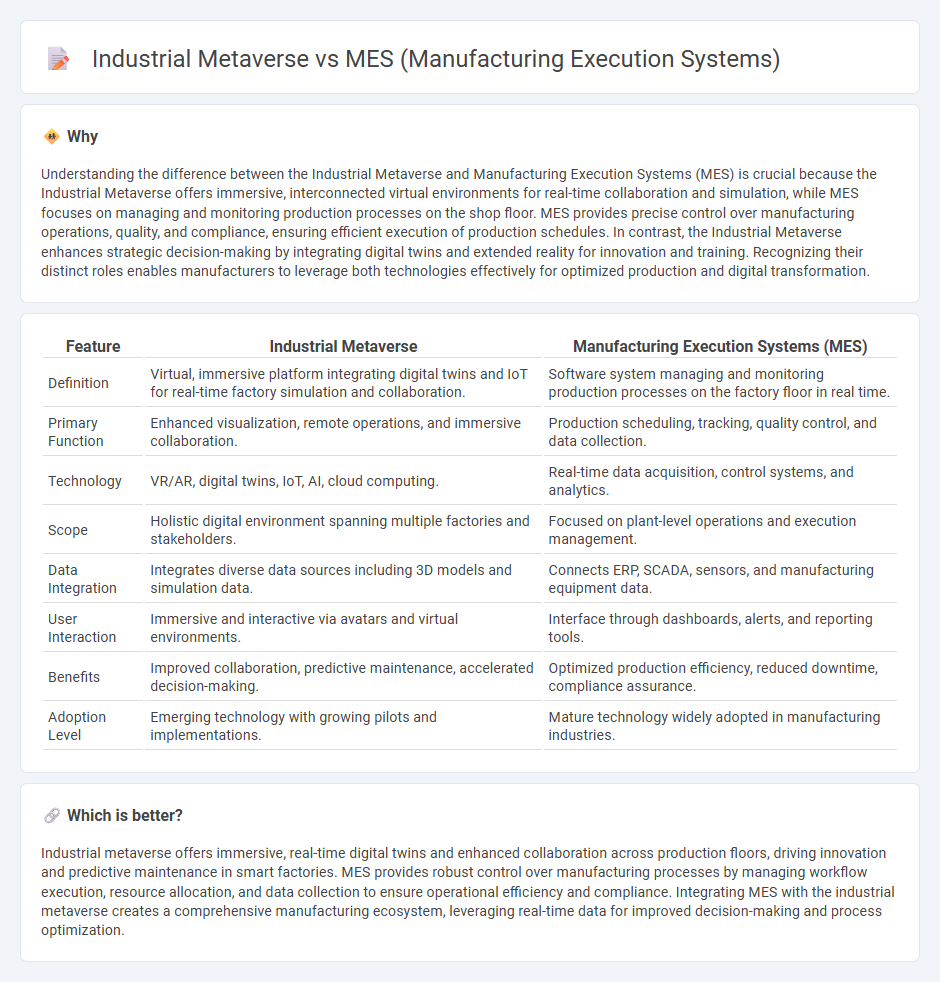

Understanding the difference between the Industrial Metaverse and Manufacturing Execution Systems (MES) is crucial because the Industrial Metaverse offers immersive, interconnected virtual environments for real-time collaboration and simulation, while MES focuses on managing and monitoring production processes on the shop floor. MES provides precise control over manufacturing operations, quality, and compliance, ensuring efficient execution of production schedules. In contrast, the Industrial Metaverse enhances strategic decision-making by integrating digital twins and extended reality for innovation and training. Recognizing their distinct roles enables manufacturers to leverage both technologies effectively for optimized production and digital transformation.

Comparison Table

| Feature | Industrial Metaverse | Manufacturing Execution Systems (MES) |

|---|---|---|

| Definition | Virtual, immersive platform integrating digital twins and IoT for real-time factory simulation and collaboration. | Software system managing and monitoring production processes on the factory floor in real time. |

| Primary Function | Enhanced visualization, remote operations, and immersive collaboration. | Production scheduling, tracking, quality control, and data collection. |

| Technology | VR/AR, digital twins, IoT, AI, cloud computing. | Real-time data acquisition, control systems, and analytics. |

| Scope | Holistic digital environment spanning multiple factories and stakeholders. | Focused on plant-level operations and execution management. |

| Data Integration | Integrates diverse data sources including 3D models and simulation data. | Connects ERP, SCADA, sensors, and manufacturing equipment data. |

| User Interaction | Immersive and interactive via avatars and virtual environments. | Interface through dashboards, alerts, and reporting tools. |

| Benefits | Improved collaboration, predictive maintenance, accelerated decision-making. | Optimized production efficiency, reduced downtime, compliance assurance. |

| Adoption Level | Emerging technology with growing pilots and implementations. | Mature technology widely adopted in manufacturing industries. |

Which is better?

Industrial metaverse offers immersive, real-time digital twins and enhanced collaboration across production floors, driving innovation and predictive maintenance in smart factories. MES provides robust control over manufacturing processes by managing workflow execution, resource allocation, and data collection to ensure operational efficiency and compliance. Integrating MES with the industrial metaverse creates a comprehensive manufacturing ecosystem, leveraging real-time data for improved decision-making and process optimization.

Connection

The Industrial metaverse integrates digital twins and virtual simulations with Manufacturing Execution Systems (MES) to enhance real-time production monitoring and decision-making. MES collects and manages shop floor data, while the Industrial metaverse provides immersive visualization and predictive analytics for optimizing manufacturing processes. This synergy accelerates smart factory initiatives by improving operational efficiency, asset utilization, and quality control within Industry 4.0 environments.

Key Terms

Real-time data integration

MES systems enable real-time data integration by collecting and analyzing live production data to optimize manufacturing processes and improve efficiency. The industrial metaverse extends this concept, creating immersive digital twins that integrate real-time sensor data, AI, and IoT to simulate, predict, and enhance factory operations across virtual and physical environments. Explore how these technologies transform industrial data management and operational insights.

Digital twin

Manufacturing Execution Systems (MES) are real-time control systems that track and document the transformation of raw materials to finished goods on the factory floor, ensuring production efficiency and quality. The Industrial Metaverse leverages digital twin technology to create immersive, interactive virtual replicas of physical manufacturing environments, enabling enhanced simulation, predictive maintenance, and remote collaboration. To explore how digital twins bridge MES capabilities with Industrial Metaverse innovations, discover more about their integrated applications in modern manufacturing.

Virtual collaboration

Manufacturing Execution Systems (MES) manage real-time production processes and data, ensuring operational efficiency on the factory floor. Industrial metaverse platforms enhance virtual collaboration by creating immersive 3D environments where engineers and operators can interact, simulate, and troubleshoot production scenarios remotely. Explore how integrating MES with industrial metaverse tools can revolutionize virtual collaboration in manufacturing.

Source and External Links

Manufacturing execution system - Wikipedia - MES (Manufacturing Execution Systems) are computerized software systems that track and document the transformation of raw materials into finished goods, providing real-time monitoring and control of production processes to optimize efficiency, manage resources, ensure quality, and create detailed production records, often integrating with ERP systems for comprehensive manufacturing oversight.

What is a Manufacturing Execution System (MES)? - IBM - An MES is a software-based solution that bridges enterprise planning systems (ERP) and shop floor control, offering real-time tracking and documentation of production, enabling quality assurance, resource optimization, downtime reduction, and informed decision-making for manufacturing operations.

The MES Beginners Guide | Rockwell Automation | Plex | US - MES software tracks real-time data across the production lifecycle and equipment, connecting, monitoring, and controlling factory floor operations to improve transparency, track product genealogy, and provide insights to optimize manufacturing efficiency.

dowidth.com

dowidth.com