Green steel production significantly reduces carbon emissions by using renewable energy and hydrogen instead of coal, unlike traditional grey steel which relies heavily on carbon-intensive blast furnaces. This innovative approach not only supports global climate goals but also enhances resource efficiency and sustainability in the manufacturing sector. Discover how green steel is transforming the future of steel production.

Why it is important

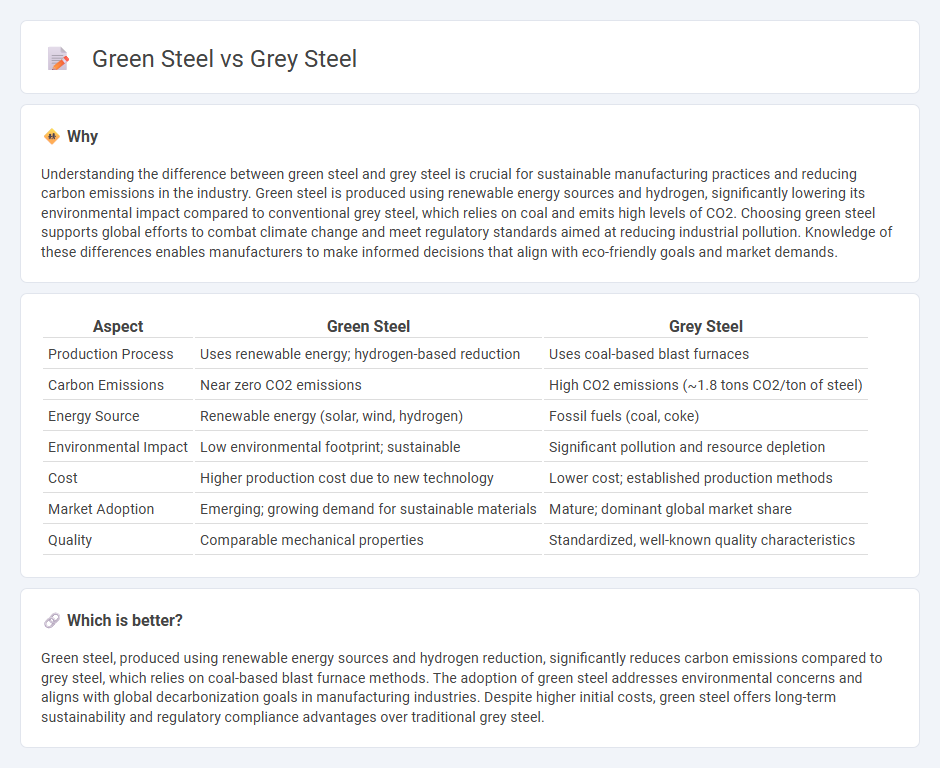

Understanding the difference between green steel and grey steel is crucial for sustainable manufacturing practices and reducing carbon emissions in the industry. Green steel is produced using renewable energy sources and hydrogen, significantly lowering its environmental impact compared to conventional grey steel, which relies on coal and emits high levels of CO2. Choosing green steel supports global efforts to combat climate change and meet regulatory standards aimed at reducing industrial pollution. Knowledge of these differences enables manufacturers to make informed decisions that align with eco-friendly goals and market demands.

Comparison Table

| Aspect | Green Steel | Grey Steel |

|---|---|---|

| Production Process | Uses renewable energy; hydrogen-based reduction | Uses coal-based blast furnaces |

| Carbon Emissions | Near zero CO2 emissions | High CO2 emissions (~1.8 tons CO2/ton of steel) |

| Energy Source | Renewable energy (solar, wind, hydrogen) | Fossil fuels (coal, coke) |

| Environmental Impact | Low environmental footprint; sustainable | Significant pollution and resource depletion |

| Cost | Higher production cost due to new technology | Lower cost; established production methods |

| Market Adoption | Emerging; growing demand for sustainable materials | Mature; dominant global market share |

| Quality | Comparable mechanical properties | Standardized, well-known quality characteristics |

Which is better?

Green steel, produced using renewable energy sources and hydrogen reduction, significantly reduces carbon emissions compared to grey steel, which relies on coal-based blast furnace methods. The adoption of green steel addresses environmental concerns and aligns with global decarbonization goals in manufacturing industries. Despite higher initial costs, green steel offers long-term sustainability and regulatory compliance advantages over traditional grey steel.

Connection

Green steel and grey steel are connected through their production processes, where green steel is produced using renewable energy and low-carbon technologies, contrasting with grey steel's reliance on fossil fuels and high carbon emissions. The steel industry aims to transition from grey to green steel to reduce its substantial environmental impact, as steel production accounts for approximately 7-9% of global CO2 emissions. Innovations such as hydrogen-based direct reduction and electric arc furnaces enable this shift, linking the traditional grey steel infrastructure with emerging green steel technologies.

Key Terms

Carbon Emissions

Grey steel production is the traditional method relying on coal and coke, resulting in high carbon emissions, contributing approximately 7-9% of global CO2 emissions. Green steel uses hydrogen and renewable energy sources, drastically reducing or nearly eliminating carbon emissions during production. Explore how green steel revolutionizes sustainable manufacturing and environmental impact reduction.

Production Process

Grey steel production relies heavily on fossil fuels, primarily coal, resulting in significant carbon emissions during the blast furnace and basic oxygen furnace processes. Green steel utilizes renewable energy sources and hydrogen-based direct reduction methods to drastically reduce or eliminate CO2 emissions in manufacturing. Explore the advancements in green steel technologies to understand their impact on sustainable production.

Energy Source

Grey steel production primarily relies on coal-based blast furnaces, emitting significant carbon dioxide and contributing to environmental pollution. In contrast, green steel utilizes renewable energy sources such as hydrogen produced via electrolysis powered by wind or solar, resulting in near-zero carbon emissions. Explore the innovative energy solutions driving the transition from grey to green steel.

Source and External Links

Greysteel - Greysteel is a middle market focused real estate investment banking firm, serving private and institutional investors across the United States.

Greysteel--The Barbell Prescription and The Athlete of Aging - This video discusses fitness and aging, featuring Dr. Jonathon Sullivan and his approach to strength training for older adults.

Grey Steel 2 - This is a cool neutral paint color offered by Dulux, suitable for various interior design settings.

dowidth.com

dowidth.com