Machine vision systems leverage advanced cameras and AI algorithms to enhance quality inspection and defect detection, significantly reducing production errors. Process control employs sensors and automated feedback loops to maintain optimal operational parameters, ensuring consistent product quality and efficiency. Discover deeper insights into how integrating machine vision with process control can revolutionize manufacturing performance.

Why it is important

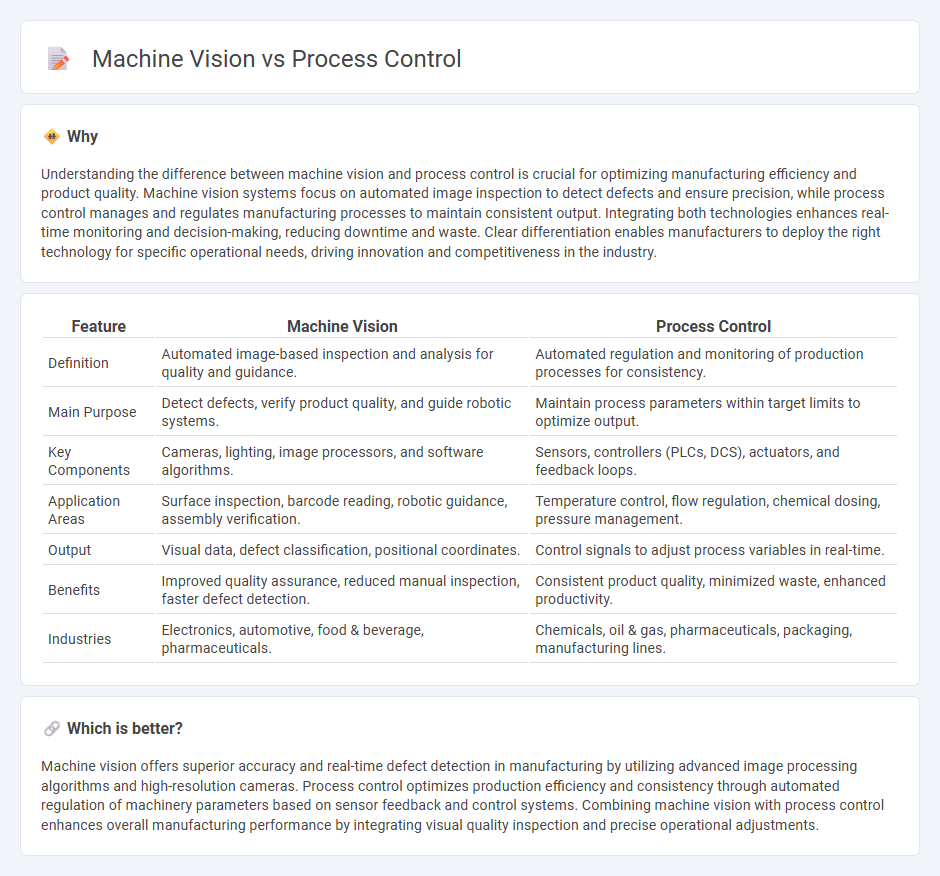

Understanding the difference between machine vision and process control is crucial for optimizing manufacturing efficiency and product quality. Machine vision systems focus on automated image inspection to detect defects and ensure precision, while process control manages and regulates manufacturing processes to maintain consistent output. Integrating both technologies enhances real-time monitoring and decision-making, reducing downtime and waste. Clear differentiation enables manufacturers to deploy the right technology for specific operational needs, driving innovation and competitiveness in the industry.

Comparison Table

| Feature | Machine Vision | Process Control |

|---|---|---|

| Definition | Automated image-based inspection and analysis for quality and guidance. | Automated regulation and monitoring of production processes for consistency. |

| Main Purpose | Detect defects, verify product quality, and guide robotic systems. | Maintain process parameters within target limits to optimize output. |

| Key Components | Cameras, lighting, image processors, and software algorithms. | Sensors, controllers (PLCs, DCS), actuators, and feedback loops. |

| Application Areas | Surface inspection, barcode reading, robotic guidance, assembly verification. | Temperature control, flow regulation, chemical dosing, pressure management. |

| Output | Visual data, defect classification, positional coordinates. | Control signals to adjust process variables in real-time. |

| Benefits | Improved quality assurance, reduced manual inspection, faster defect detection. | Consistent product quality, minimized waste, enhanced productivity. |

| Industries | Electronics, automotive, food & beverage, pharmaceuticals. | Chemicals, oil & gas, pharmaceuticals, packaging, manufacturing lines. |

Which is better?

Machine vision offers superior accuracy and real-time defect detection in manufacturing by utilizing advanced image processing algorithms and high-resolution cameras. Process control optimizes production efficiency and consistency through automated regulation of machinery parameters based on sensor feedback and control systems. Combining machine vision with process control enhances overall manufacturing performance by integrating visual quality inspection and precise operational adjustments.

Connection

Machine vision systems enhance manufacturing process control by providing real-time visual data that enables precise monitoring and automatic adjustments on production lines. Integration of machine vision with process control software improves defect detection, quality assurance, and operational efficiency through immediate feedback loops. This synergy reduces downtime, minimizes waste, and supports predictive maintenance by continuously analyzing visual inputs to optimize manufacturing workflows.

Key Terms

Process control:

Process control systems regulate manufacturing processes by continuously monitoring variables such as temperature, pressure, and flow rate to ensure product quality and operational efficiency. These systems utilize sensors, controllers, and actuators to maintain optimal conditions and minimize variability in production lines. Discover how advanced process control technologies can enhance accuracy and reduce downtime in industrial applications.

Feedback Loop

Process control relies on real-time feedback loops to monitor and adjust parameters, ensuring consistent production quality and efficiency. Machine vision systems provide critical data inputs by capturing and analyzing visual information, enhancing the accuracy of the feedback loop in identifying defects or deviations. Explore how integrating these technologies can optimize automated manufacturing processes and boost operational performance.

Sensors

Process control relies heavily on sensors such as pressure transmitters, flow meters, and temperature sensors to monitor and regulate industrial operations for consistent quality and safety. Machine vision incorporates sensors like industrial cameras and light sensors to capture and analyze visual data, enabling defect detection, guidance, and automated inspection. Explore the latest advancements in sensor technology to optimize both process control and machine vision systems.

Source and External Links

What is Process Control in Manufacturing? - Process control is a set of automated procedures using feedback loops and AI/ML technologies to monitor and adjust variables like temperature or pressure in manufacturing, ensuring quality and efficiency in production processes.

Industrial process control - Industrial process control uses control theory and automated systems like PLCs or DCS including sensors and actuators to continuously monitor and regulate industrial manufacturing processes, maintaining stability and quality through closed-loop feedback.

What is Process Control? - Process control monitors and adjusts process parameters in industrial automation to optimize output quality, energy efficiency, throughput, and safety.

dowidth.com

dowidth.com