Manufacturing is evolving through servitization, which integrates services like maintenance and customization to enhance product value, contrasting with productization that focuses on standardizing products for mass production and scalability. Servitization drives customer loyalty by offering tailored solutions, while productization emphasizes efficiency and cost reduction through uniformity. Explore how these strategies reshape manufacturing competitiveness and innovation.

Why it is important

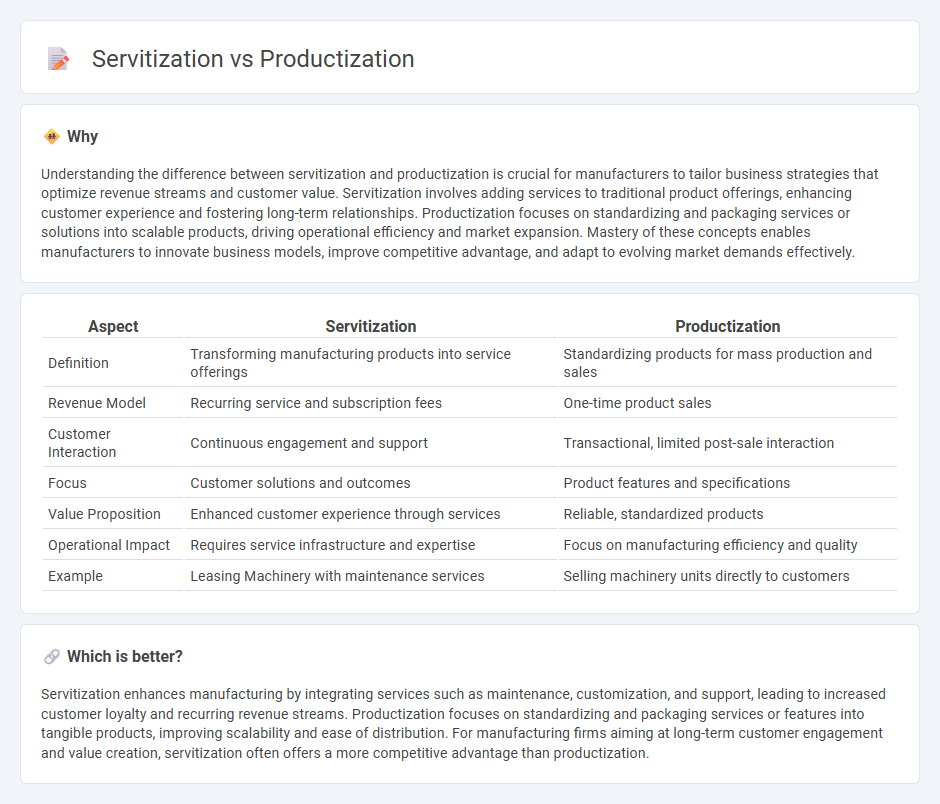

Understanding the difference between servitization and productization is crucial for manufacturers to tailor business strategies that optimize revenue streams and customer value. Servitization involves adding services to traditional product offerings, enhancing customer experience and fostering long-term relationships. Productization focuses on standardizing and packaging services or solutions into scalable products, driving operational efficiency and market expansion. Mastery of these concepts enables manufacturers to innovate business models, improve competitive advantage, and adapt to evolving market demands effectively.

Comparison Table

| Aspect | Servitization | Productization |

|---|---|---|

| Definition | Transforming manufacturing products into service offerings | Standardizing products for mass production and sales |

| Revenue Model | Recurring service and subscription fees | One-time product sales |

| Customer Interaction | Continuous engagement and support | Transactional, limited post-sale interaction |

| Focus | Customer solutions and outcomes | Product features and specifications |

| Value Proposition | Enhanced customer experience through services | Reliable, standardized products |

| Operational Impact | Requires service infrastructure and expertise | Focus on manufacturing efficiency and quality |

| Example | Leasing Machinery with maintenance services | Selling machinery units directly to customers |

Which is better?

Servitization enhances manufacturing by integrating services such as maintenance, customization, and support, leading to increased customer loyalty and recurring revenue streams. Productization focuses on standardizing and packaging services or features into tangible products, improving scalability and ease of distribution. For manufacturing firms aiming at long-term customer engagement and value creation, servitization often offers a more competitive advantage than productization.

Connection

Servitization transforms traditional manufacturing by integrating services such as maintenance and support into physical products, enhancing customer value and fostering long-term relationships. Productization standardizes these service offerings into scalable, repeatable packages, enabling manufacturers to efficiently deliver consistent solutions. Together, servitization and productization shift manufacturing business models from one-time sales to continuous revenue streams driven by service-based innovation.

Key Terms

Tangible Goods

Productization emphasizes transforming services or ideas into standardized, tangible goods that enhance scalability and market reach. Servitization, by contrast, integrates services with physical products to deliver comprehensive customer solutions, increasing value through ongoing support and customization. Explore the benefits and strategies of productization and servitization to optimize your tangible goods offerings.

Value-added Services

Productization transforms services into standardized products to enhance scalability and customer experience, while servitization integrates value-added services into traditional product offerings to create competitive differentiation and foster customer loyalty. Companies leveraging value-added services in servitization achieve higher revenue streams and improved customer satisfaction by offering maintenance, customization, and support solutions. Explore the strategic benefits of value-added services through productization and servitization to elevate your business model.

Business Model Transformation

Productization transforms services into standardized, marketable products, enabling scalability and efficient revenue streams. Servitization shifts a company's focus from selling products to offering comprehensive service solutions, enhancing customer value through tailored experiences and ongoing support. Explore how these strategies drive business model transformation and create competitive advantages.

Source and External Links

Productization in Construction: Efficiency and Innovation - Productization in construction means using digital-led, standardized processes and prefabricated components to improve efficiency, quality, and cost, while enabling repeatable and scalable project delivery.

How to Make Your Product the Next Big Mac - Productization is turning custom or craft-based offerings into standardized, repeatable products--like a Big Mac or iPhone--which streamlines operations, reduces costs, and enables growth.

Productization: Turning Services Into Products - In professional services, productization involves packaging expertise, data, or methodologies into scalable, tech-enabled tools or programs that clients can buy and use, moving beyond custom consulting to repeatable, defined offerings.

dowidth.com

dowidth.com