Lights-out manufacturing employs fully automated factories operating without human intervention, enhancing efficiency and reducing labor costs. Additive manufacturing, or 3D printing, builds products layer by layer, allowing for complex geometries and customization with minimal material waste. Explore the differences to understand which advanced manufacturing technology suits your production needs best.

Why it is important

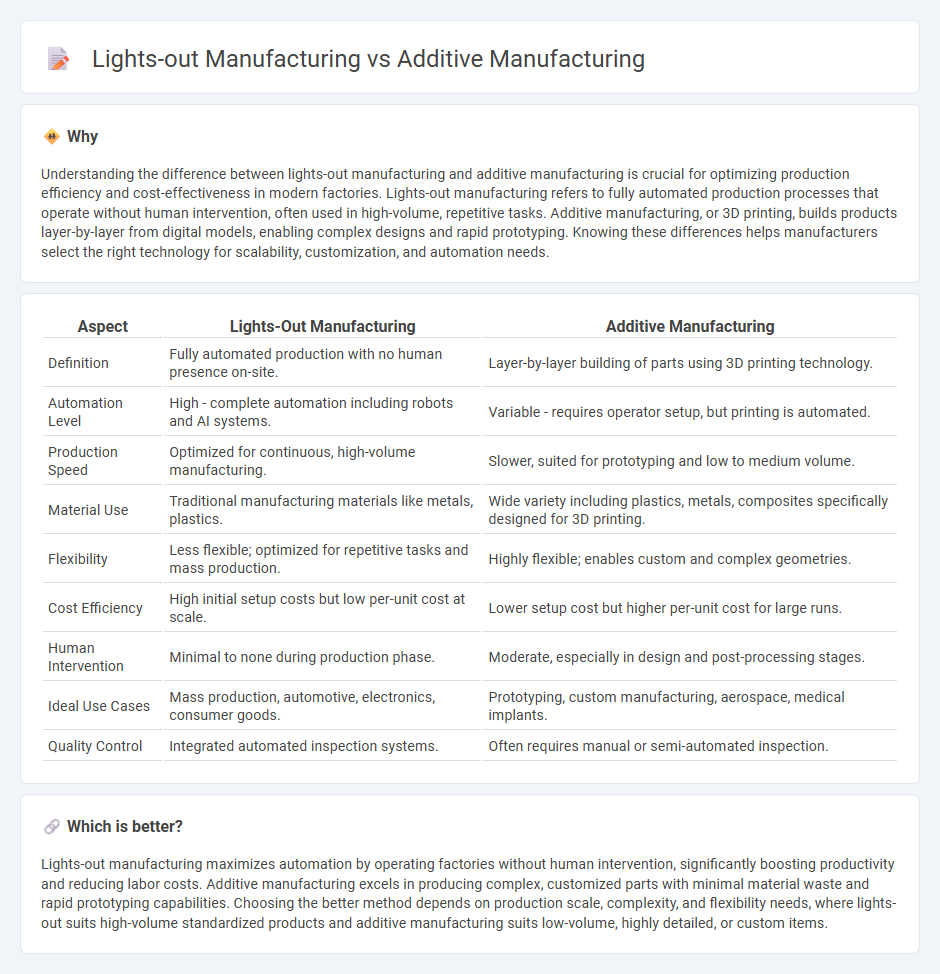

Understanding the difference between lights-out manufacturing and additive manufacturing is crucial for optimizing production efficiency and cost-effectiveness in modern factories. Lights-out manufacturing refers to fully automated production processes that operate without human intervention, often used in high-volume, repetitive tasks. Additive manufacturing, or 3D printing, builds products layer-by-layer from digital models, enabling complex designs and rapid prototyping. Knowing these differences helps manufacturers select the right technology for scalability, customization, and automation needs.

Comparison Table

| Aspect | Lights-Out Manufacturing | Additive Manufacturing |

|---|---|---|

| Definition | Fully automated production with no human presence on-site. | Layer-by-layer building of parts using 3D printing technology. |

| Automation Level | High - complete automation including robots and AI systems. | Variable - requires operator setup, but printing is automated. |

| Production Speed | Optimized for continuous, high-volume manufacturing. | Slower, suited for prototyping and low to medium volume. |

| Material Use | Traditional manufacturing materials like metals, plastics. | Wide variety including plastics, metals, composites specifically designed for 3D printing. |

| Flexibility | Less flexible; optimized for repetitive tasks and mass production. | Highly flexible; enables custom and complex geometries. |

| Cost Efficiency | High initial setup costs but low per-unit cost at scale. | Lower setup cost but higher per-unit cost for large runs. |

| Human Intervention | Minimal to none during production phase. | Moderate, especially in design and post-processing stages. |

| Ideal Use Cases | Mass production, automotive, electronics, consumer goods. | Prototyping, custom manufacturing, aerospace, medical implants. |

| Quality Control | Integrated automated inspection systems. | Often requires manual or semi-automated inspection. |

Which is better?

Lights-out manufacturing maximizes automation by operating factories without human intervention, significantly boosting productivity and reducing labor costs. Additive manufacturing excels in producing complex, customized parts with minimal material waste and rapid prototyping capabilities. Choosing the better method depends on production scale, complexity, and flexibility needs, where lights-out suits high-volume standardized products and additive manufacturing suits low-volume, highly detailed, or custom items.

Connection

Lights-out manufacturing leverages automation and robotics to operate production facilities without human intervention, enhancing efficiency and reducing labor costs. Additive manufacturing, or 3D printing, complements this by enabling on-demand, precise production of complex parts directly from digital files, minimizing material waste and setup time. The integration of additive manufacturing within lights-out facilities accelerates manufacturing cycles, supports mass customization, and streamlines supply chains through seamless digital workflows.

Key Terms

3D Printing

Additive manufacturing, commonly known as 3D printing, builds objects layer by layer from digital models, allowing for intricate geometries and rapid prototyping. Lights-out manufacturing emphasizes fully automated production processes that operate without human intervention, improving efficiency and reducing labor costs. Explore more about how these advanced manufacturing methods transform production efficiency and innovation.

Automation

Additive manufacturing utilizes automation by enabling layer-by-layer construction with minimal human intervention, improving precision and reducing waste. Lights-out manufacturing achieves higher automation levels by operating equipment entirely unattended through AI-driven monitoring and robotic systems, maximizing production efficiency. Explore how integrating these technologies can revolutionize automated manufacturing processes.

Unmanned Operations

Additive manufacturing revolutionizes production by enabling layer-by-layer building of complex parts with minimal human intervention, optimizing unmanned operations through automation and digital precision. Lights-out manufacturing further enhances efficiency by operating entire facilities without human presence, relying heavily on robotics, AI, and real-time monitoring to maintain continuous production. Explore how integrating additive manufacturing within lights-out frameworks transforms industrial workflows for unprecedented productivity.

Source and External Links

Additive manufacturing, explained | MIT Sloan - Additive manufacturing is the process of building an object one layer at a time using digital designs, often referred to as 3D printing, and contrasts with traditional subtractive manufacturing methods by minimizing waste and enabling direct digital-to-physical fabrication of complex parts from a variety of materials such as plastics, metals, and ceramics.

Additive manufacturing | NIST - Additive manufacturing (AM) fabricates three-dimensional objects by precisely depositing materials layer by layer from digital designs, allowing for customized, complex geometries and reduced material waste compared to conventional manufacturing, and is widely applicable across aerospace, medical, and other industries.

The 7 categories of Additive Manufacturing - Loughborough University - ASTM standards classify additive manufacturing into seven distinct process categories--such as vat photopolymerization, material jetting, and binder jetting--each differing in how layers are formed and bonded, highlighting the diversity of AM technologies beyond the common "3D printing" label.

dowidth.com

dowidth.com