Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation to streamline manufacturing workflows and enhance efficiency. Autonomous production involves self-operating machines and systems that perform manufacturing tasks with minimal human intervention, driven by real-time data and intelligent controls. Explore the differences and benefits of hyperautomation versus autonomous production to optimize manufacturing processes.

Why it is important

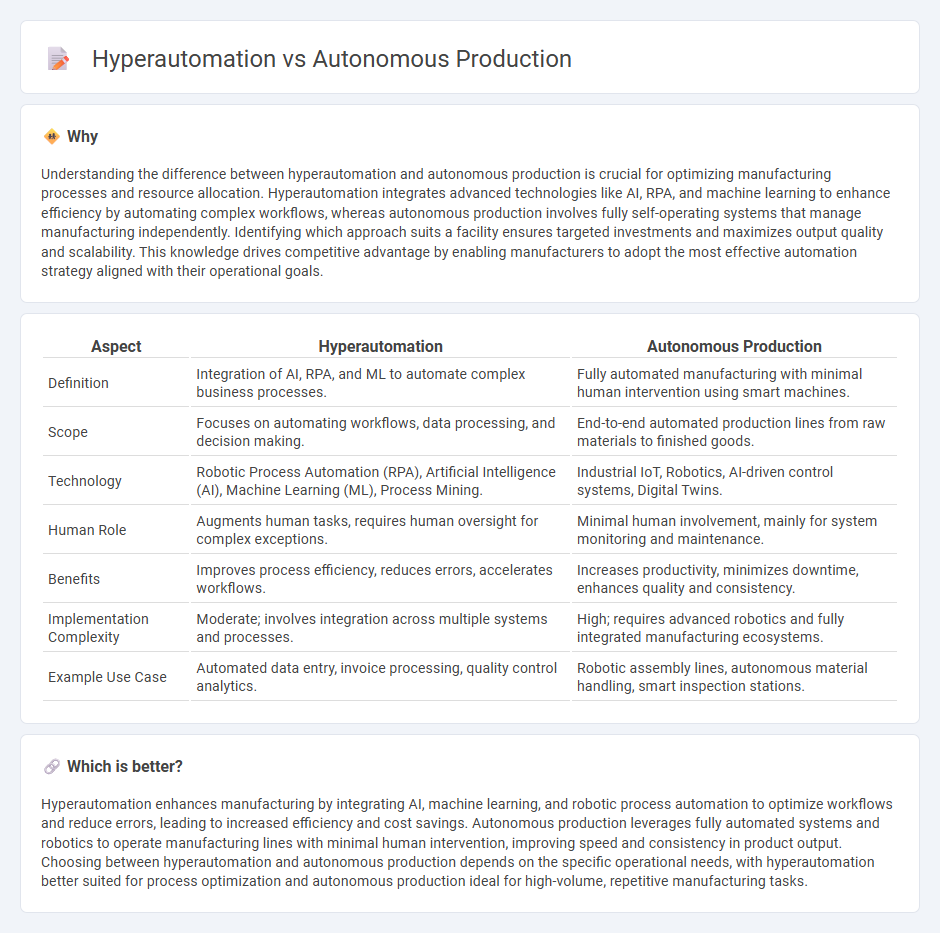

Understanding the difference between hyperautomation and autonomous production is crucial for optimizing manufacturing processes and resource allocation. Hyperautomation integrates advanced technologies like AI, RPA, and machine learning to enhance efficiency by automating complex workflows, whereas autonomous production involves fully self-operating systems that manage manufacturing independently. Identifying which approach suits a facility ensures targeted investments and maximizes output quality and scalability. This knowledge drives competitive advantage by enabling manufacturers to adopt the most effective automation strategy aligned with their operational goals.

Comparison Table

| Aspect | Hyperautomation | Autonomous Production |

|---|---|---|

| Definition | Integration of AI, RPA, and ML to automate complex business processes. | Fully automated manufacturing with minimal human intervention using smart machines. |

| Scope | Focuses on automating workflows, data processing, and decision making. | End-to-end automated production lines from raw materials to finished goods. |

| Technology | Robotic Process Automation (RPA), Artificial Intelligence (AI), Machine Learning (ML), Process Mining. | Industrial IoT, Robotics, AI-driven control systems, Digital Twins. |

| Human Role | Augments human tasks, requires human oversight for complex exceptions. | Minimal human involvement, mainly for system monitoring and maintenance. |

| Benefits | Improves process efficiency, reduces errors, accelerates workflows. | Increases productivity, minimizes downtime, enhances quality and consistency. |

| Implementation Complexity | Moderate; involves integration across multiple systems and processes. | High; requires advanced robotics and fully integrated manufacturing ecosystems. |

| Example Use Case | Automated data entry, invoice processing, quality control analytics. | Robotic assembly lines, autonomous material handling, smart inspection stations. |

Which is better?

Hyperautomation enhances manufacturing by integrating AI, machine learning, and robotic process automation to optimize workflows and reduce errors, leading to increased efficiency and cost savings. Autonomous production leverages fully automated systems and robotics to operate manufacturing lines with minimal human intervention, improving speed and consistency in product output. Choosing between hyperautomation and autonomous production depends on the specific operational needs, with hyperautomation better suited for process optimization and autonomous production ideal for high-volume, repetitive manufacturing tasks.

Connection

Hyperautomation integrates advanced technologies like AI, robotics, and IoT to streamline manufacturing processes, enabling autonomous production systems to operate with minimal human intervention. Autonomous production leverages real-time data analytics and machine learning models from hyperautomation to optimize workflows, reduce errors, and increase efficiency. This synergy accelerates production cycles, enhances precision, and supports adaptive manufacturing environments.

Key Terms

Industrial IoT (IIoT)

Autonomous production leverages Industrial IoT (IIoT) to enable machines and systems to operate independently with minimal human intervention, enhancing efficiency and reducing downtime through real-time data analysis and predictive maintenance. Hyperautomation integrates IIoT with advanced technologies like AI, machine learning, and robotic process automation to automate complex industrial workflows end-to-end, driving superior scalability and operational agility. Explore how combining autonomous production and hyperautomation in IIoT ecosystems transforms manufacturing competitiveness and innovation.

Robotics Process Automation (RPA)

Robotics Process Automation (RPA) drives hyperautomation by integrating AI, machine learning, and advanced analytics to automate complex, multi-step workflows beyond traditional autonomous production capabilities. Autonomous production emphasizes machinery and systems performing predefined manufacturing tasks with minimal human intervention, whereas hyperautomation leverages RPA to orchestrate and optimize end-to-end business processes across various functions. Explore in-depth insights on how RPA transforms automation landscapes by visiting our comprehensive resource center.

Artificial Intelligence (AI)

Autonomous production leverages Artificial Intelligence (AI) to enable machines and systems to operate independently with minimal human intervention, enhancing efficiency by automating complex processes within manufacturing environments. Hyperautomation extends this concept by integrating AI with robotic process automation (RPA), machine learning, and advanced analytics to automate end-to-end business workflows beyond production lines, fostering a holistic digital transformation. Discover how AI-driven innovations in autonomous production and hyperautomation are revolutionizing industrial and operational landscapes.

Source and External Links

Navigating the Path to Autonomous Manufacturing - Autonomous production is an advanced manufacturing stage where AI-driven machines and robots operate with minimal human intervention to boost efficiency, quality, safety, cost savings, and flexibility.

From automation to autonomous: The future of industrial ... - Autonomous manufacturing integrates AI, robotics, and IoT into workflows, enabling real-time process optimization and better decision-making while transforming human roles in manufacturing.

From Industrial Automation to Autonomous Production - Autonomous production aims for factories that self-operate 24/7, producing highly customized small batches using AI-driven machine vision, decentralized computing, and connected systems.

dowidth.com

dowidth.com