Condition monitoring focuses on tracking the physical state and health of manufacturing equipment through sensors and real-time data analysis to detect faults early and prevent unexpected breakdowns. Performance monitoring measures operational efficiency, output quality, and production metrics to optimize workflows and enhance overall equipment effectiveness (OEE). Explore comprehensive insights into how condition monitoring and performance monitoring drive smarter manufacturing processes.

Why it is important

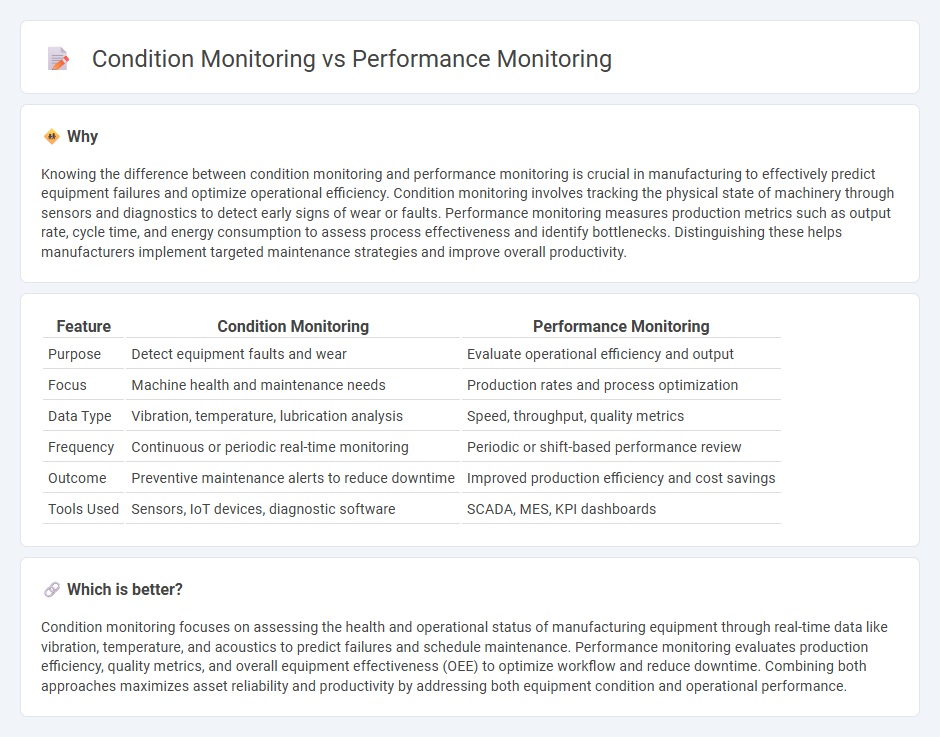

Knowing the difference between condition monitoring and performance monitoring is crucial in manufacturing to effectively predict equipment failures and optimize operational efficiency. Condition monitoring involves tracking the physical state of machinery through sensors and diagnostics to detect early signs of wear or faults. Performance monitoring measures production metrics such as output rate, cycle time, and energy consumption to assess process effectiveness and identify bottlenecks. Distinguishing these helps manufacturers implement targeted maintenance strategies and improve overall productivity.

Comparison Table

| Feature | Condition Monitoring | Performance Monitoring |

|---|---|---|

| Purpose | Detect equipment faults and wear | Evaluate operational efficiency and output |

| Focus | Machine health and maintenance needs | Production rates and process optimization |

| Data Type | Vibration, temperature, lubrication analysis | Speed, throughput, quality metrics |

| Frequency | Continuous or periodic real-time monitoring | Periodic or shift-based performance review |

| Outcome | Preventive maintenance alerts to reduce downtime | Improved production efficiency and cost savings |

| Tools Used | Sensors, IoT devices, diagnostic software | SCADA, MES, KPI dashboards |

Which is better?

Condition monitoring focuses on assessing the health and operational status of manufacturing equipment through real-time data like vibration, temperature, and acoustics to predict failures and schedule maintenance. Performance monitoring evaluates production efficiency, quality metrics, and overall equipment effectiveness (OEE) to optimize workflow and reduce downtime. Combining both approaches maximizes asset reliability and productivity by addressing both equipment condition and operational performance.

Connection

Condition monitoring collects real-time data on equipment health using sensors and diagnostic tools, enabling early fault detection and maintenance planning. Performance monitoring analyzes operational metrics such as throughput, efficiency, and energy consumption to evaluate production effectiveness. Integrating condition monitoring with performance monitoring improves asset reliability, reduces downtime, and optimizes manufacturing productivity by correlating machine condition with process performance.

Key Terms

Key Performance Indicators (KPIs)

Performance monitoring tracks Key Performance Indicators (KPIs) such as production output, efficiency, and quality metrics to evaluate operational success and identify areas for improvement. Condition monitoring emphasizes real-time data analysis from equipment sensors, measuring parameters like vibration, temperature, and pressure to predict maintenance needs and prevent failures. Explore our detailed guide to understand how integrating both approaches optimizes asset management and boosts productivity.

Predictive Maintenance

Performance monitoring tracks equipment efficiency and output metrics to identify deviations indicating potential issues, while condition monitoring uses sensors and data analytics to assess machinery health in real-time by measuring vibration, temperature, and wear. Predictive maintenance leverages data from both methods, applying machine learning algorithms to forecast failures before they occur, minimizing downtime and maintenance costs. Explore how integrating performance and condition monitoring enhances predictive maintenance strategies and operational reliability.

Sensor Data

Performance monitoring analyzes sensor data to assess the efficiency and output quality of machinery, tracking metrics such as speed, temperature, and vibration to optimize operational performance. Condition monitoring focuses on sensor data to detect early signs of equipment degradation or failure, using techniques like vibration analysis and thermal imaging to predict maintenance needs and prevent downtime. Discover how sensor-driven insights enhance both performance and condition monitoring strategies.

Source and External Links

What is performance monitoring? - Dynatrace - Performance monitoring is the IT practice of automatically collecting metrics, distributed traces, and logs to observe application and infrastructure performance, detect bottlenecks, and ensure services meet service-level objectives by providing data visualizations and alerts for anomalies.

What is APM? - Application Performance Monitoring Explained - AWS - Application Performance Monitoring (APM) is software-based monitoring that tracks metrics such as CPU usage, response times, error rates, transaction tracing, instances, requests, and uptime to ensure the health and performance of business-critical applications.

What is Application Performance Monitoring? A Detailed Guide - APM involves real-time tracking, diagnosing, and optimizing software applications by monitoring telemetry data on latency, resource usage, error rates, and dependencies to improve scalability, detect issues, and enhance user experience.

dowidth.com

dowidth.com