Remanufacturing restores used products to like-new condition through comprehensive disassembly and component replacement, enhancing sustainability and reducing waste in manufacturing processes. Remanufacturing-as-a-Service (RaaS) enables companies to outsource these complex refurbishing tasks to specialized providers, leveraging advanced technologies and expertise while lowering operational costs. Explore the advantages and applications of remanufacturing and RaaS to optimize your manufacturing strategy.

Why it is important

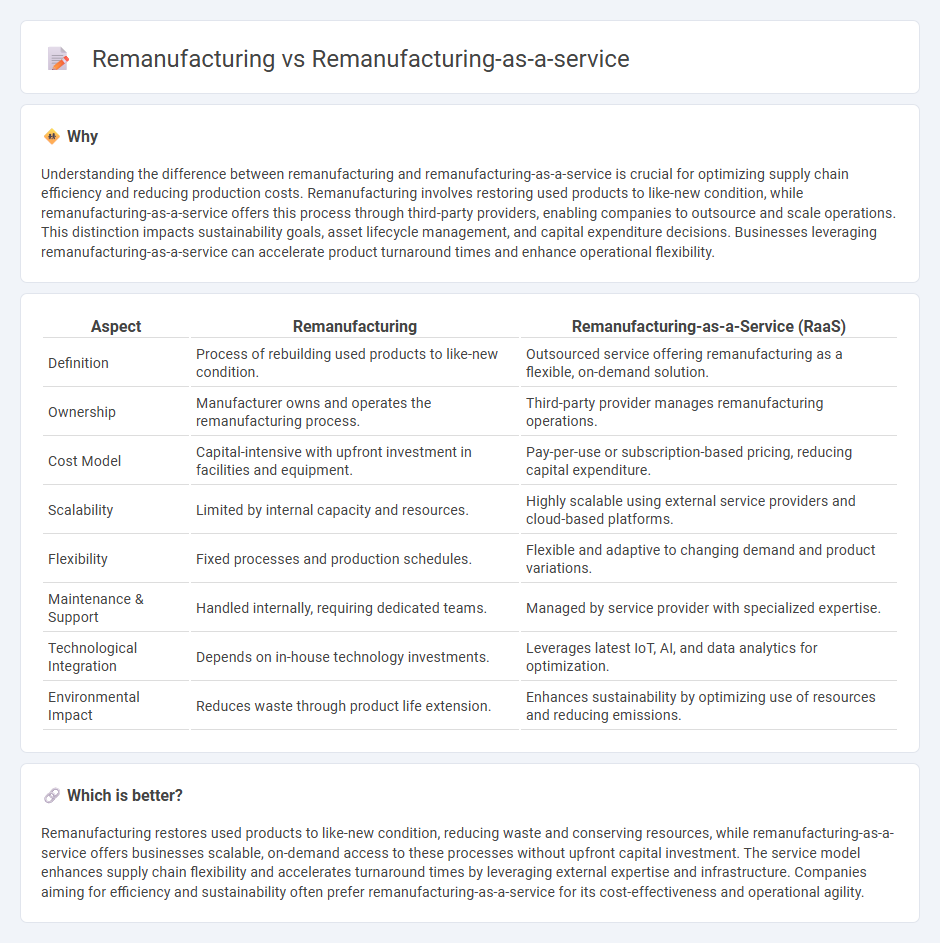

Understanding the difference between remanufacturing and remanufacturing-as-a-service is crucial for optimizing supply chain efficiency and reducing production costs. Remanufacturing involves restoring used products to like-new condition, while remanufacturing-as-a-service offers this process through third-party providers, enabling companies to outsource and scale operations. This distinction impacts sustainability goals, asset lifecycle management, and capital expenditure decisions. Businesses leveraging remanufacturing-as-a-service can accelerate product turnaround times and enhance operational flexibility.

Comparison Table

| Aspect | Remanufacturing | Remanufacturing-as-a-Service (RaaS) |

|---|---|---|

| Definition | Process of rebuilding used products to like-new condition. | Outsourced service offering remanufacturing as a flexible, on-demand solution. |

| Ownership | Manufacturer owns and operates the remanufacturing process. | Third-party provider manages remanufacturing operations. |

| Cost Model | Capital-intensive with upfront investment in facilities and equipment. | Pay-per-use or subscription-based pricing, reducing capital expenditure. |

| Scalability | Limited by internal capacity and resources. | Highly scalable using external service providers and cloud-based platforms. |

| Flexibility | Fixed processes and production schedules. | Flexible and adaptive to changing demand and product variations. |

| Maintenance & Support | Handled internally, requiring dedicated teams. | Managed by service provider with specialized expertise. |

| Technological Integration | Depends on in-house technology investments. | Leverages latest IoT, AI, and data analytics for optimization. |

| Environmental Impact | Reduces waste through product life extension. | Enhances sustainability by optimizing use of resources and reducing emissions. |

Which is better?

Remanufacturing restores used products to like-new condition, reducing waste and conserving resources, while remanufacturing-as-a-service offers businesses scalable, on-demand access to these processes without upfront capital investment. The service model enhances supply chain flexibility and accelerates turnaround times by leveraging external expertise and infrastructure. Companies aiming for efficiency and sustainability often prefer remanufacturing-as-a-service for its cost-effectiveness and operational agility.

Connection

Remanufacturing involves restoring used products to like-new condition through comprehensive rebuilding processes, significantly reducing material waste and resource consumption. Remanufacturing-as-a-service (RaaS) leverages this concept by offering businesses scalable, on-demand remanufacturing solutions that optimize supply chains and lower operational costs. This service model integrates advanced technologies such as IoT and data analytics to enhance product lifecycle management and promote circular economy practices within manufacturing industries.

Key Terms

Remanufacturing-as-a-Service:

Remanufacturing-as-a-Service (RaaS) leverages cloud computing, IoT sensors, and real-time data analytics to optimize product lifecycle management and reduce operational costs through scalable, on-demand remanufacturing solutions. Unlike traditional remanufacturing, which requires significant capital investment in infrastructure and labor, RaaS offers companies flexible access to advanced remanufacturing technologies without substantial upfront expenses. Explore how RaaS can transform your sustainability goals and operational efficiency with cutting-edge remanufacturing capabilities.

Service-based business model

Remanufacturing-as-a-service (RaaS) leverages a service-based business model emphasizing subscription and on-demand access to remanufactured products, reducing upfront costs and enhancing scalability for clients. This model integrates IoT, predictive maintenance, and cloud analytics to optimize lifecycle management and provide continuous value, contrasting traditional remanufacturing which primarily focuses on product refurbishment and resale. Explore how RaaS transforms industrial sustainability and operational efficiency by redefining the customer relationship and asset utilization.

Subscription/PaaS contracts

Remanufacturing-as-a-Service (RaaS) leverages Subscription and Platform-as-a-Service (PaaS) models to offer scalable, on-demand access to remanufacturing solutions, enabling clients to reduce capital expenditure and gain flexible lifecycle management. Traditional remanufacturing typically involves upfront investment in equipment and inventory, limiting agility and scalability compared to RaaS, which integrates digital platforms for real-time monitoring, predictive maintenance, and process optimization. Explore how Subscription and PaaS contracts revolutionize asset recovery and sustainability in manufacturing ecosystems.

Source and External Links

The manufacturer's value chain as a service: The case of remanufacturing - This academic paper conceptualizes remanufacturing as a service (RaaS) as a part of product-service strategies where manufacturers offer remanufacturing capabilities to other enterprises to gain competitive advantage and additional revenue streams by integrating remanufacturing in their value chains.

Circular Computing launches Remanufacturing-as-a-Service - Circular Computing introduced RaaS to enable companies to send laptop fleets for remanufacturing through a circular process that extends hardware life, reduces e-waste, and lowers IT procurement costs by up to 70%, supporting sustainability and ESG goals.

Remanufacturing as a Service by Total IT Global - Total IT Global's RaaS offering, called Upcycle, provides an industrial-grade remanufacturing process to restore laptops to like-new quality, addressing IT budget strain, supply chain risks, e-waste reduction, and security concerns while enhancing operational efficiency.

dowidth.com

dowidth.com