Condition monitoring employs real-time data analysis and sensor technology to detect equipment abnormalities, enabling timely interventions before failures occur. Preventive maintenance relies on scheduled inspections and routine part replacements to minimize unexpected breakdowns, based on predetermined service intervals. Explore more to understand which maintenance strategy best fits your manufacturing operations.

Why it is important

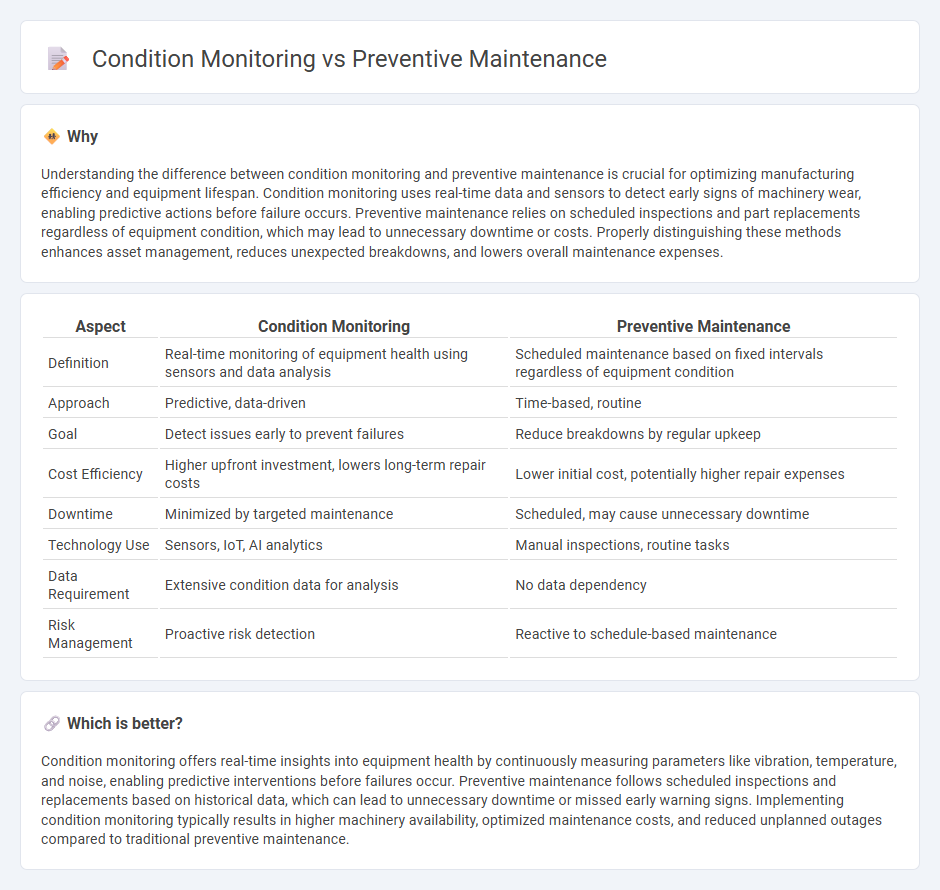

Understanding the difference between condition monitoring and preventive maintenance is crucial for optimizing manufacturing efficiency and equipment lifespan. Condition monitoring uses real-time data and sensors to detect early signs of machinery wear, enabling predictive actions before failure occurs. Preventive maintenance relies on scheduled inspections and part replacements regardless of equipment condition, which may lead to unnecessary downtime or costs. Properly distinguishing these methods enhances asset management, reduces unexpected breakdowns, and lowers overall maintenance expenses.

Comparison Table

| Aspect | Condition Monitoring | Preventive Maintenance |

|---|---|---|

| Definition | Real-time monitoring of equipment health using sensors and data analysis | Scheduled maintenance based on fixed intervals regardless of equipment condition |

| Approach | Predictive, data-driven | Time-based, routine |

| Goal | Detect issues early to prevent failures | Reduce breakdowns by regular upkeep |

| Cost Efficiency | Higher upfront investment, lowers long-term repair costs | Lower initial cost, potentially higher repair expenses |

| Downtime | Minimized by targeted maintenance | Scheduled, may cause unnecessary downtime |

| Technology Use | Sensors, IoT, AI analytics | Manual inspections, routine tasks |

| Data Requirement | Extensive condition data for analysis | No data dependency |

| Risk Management | Proactive risk detection | Reactive to schedule-based maintenance |

Which is better?

Condition monitoring offers real-time insights into equipment health by continuously measuring parameters like vibration, temperature, and noise, enabling predictive interventions before failures occur. Preventive maintenance follows scheduled inspections and replacements based on historical data, which can lead to unnecessary downtime or missed early warning signs. Implementing condition monitoring typically results in higher machinery availability, optimized maintenance costs, and reduced unplanned outages compared to traditional preventive maintenance.

Connection

Condition monitoring uses sensors and data analytics to track equipment health in real-time, enabling early detection of potential failures. Preventive maintenance relies on these insights to schedule timely interventions, minimizing unplanned downtime and extending machinery lifespan. Integrating condition monitoring with preventive maintenance optimizes manufacturing efficiency by reducing repair costs and improving asset reliability.

Key Terms

Scheduled Inspections

Scheduled inspections in preventive maintenance involve regular, time-based checks to identify potential equipment issues before failure occurs, ensuring operational reliability and reducing downtime costs. Condition monitoring relies on real-time data and sensor technologies to assess equipment health and predict maintenance needs based on actual condition rather than set intervals. Explore the benefits and implementation strategies of both approaches to optimize asset management and maintenance efficiency.

Real-time Sensors

Real-time sensors in preventive maintenance enable continuous data collection to predict equipment failures before they occur, reducing downtime and maintenance costs. Condition monitoring leverages these sensors to track machine health dynamically, allowing for timely interventions based on actual operational conditions. Explore the advances in real-time sensor technology for more efficient maintenance strategies.

Predictive Analytics

Preventive maintenance schedules regular equipment servicing to avoid failures, but condition monitoring uses real-time data and sensors to track asset health, enabling predictive analytics for more precise interventions before breakdowns occur. Predictive analytics analyzes trends and patterns from condition monitoring data to forecast potential issues, reducing downtime and optimizing maintenance costs. Explore how integrating predictive analytics with condition monitoring transforms maintenance strategies for enhanced operational efficiency.

Source and External Links

What is Preventive Maintenance? | NEXGEN Asset Management - Preventive maintenance is the practice of planned maintenance on assets to reduce risks of failure and interruptions, which can be time-based, usage-based, or predictive maintenance focused on anticipating failures before they occur.

What Is Preventive Maintenance? A Complete Guide for 2025 - Preventive maintenance involves proactive regular cleaning, inspections, lubrication, and parts replacement to reduce downtime, prevent surprise repairs, and extend equipment lifespan.

What Is Preventive Maintenance? | IBM - Preventive maintenance is a proactive approach to avoid unexpected equipment failures and safety risks by regularly inspecting and maintaining critical assets, often supported by computerized maintenance management systems (CMMS) to automate tasks and scheduling.

dowidth.com

dowidth.com