Decentralized manufacturing distributes production processes across multiple locations, enhancing flexibility and reducing supply chain risks, while additive manufacturing builds products layer by layer using 3D printing technology, enabling rapid prototyping and customization. Combining decentralized networks with additive manufacturing accelerates innovation and lowers transportation costs by producing goods closer to end-users. Explore how these manufacturing approaches revolutionize industrial efficiency and agility.

Why it is important

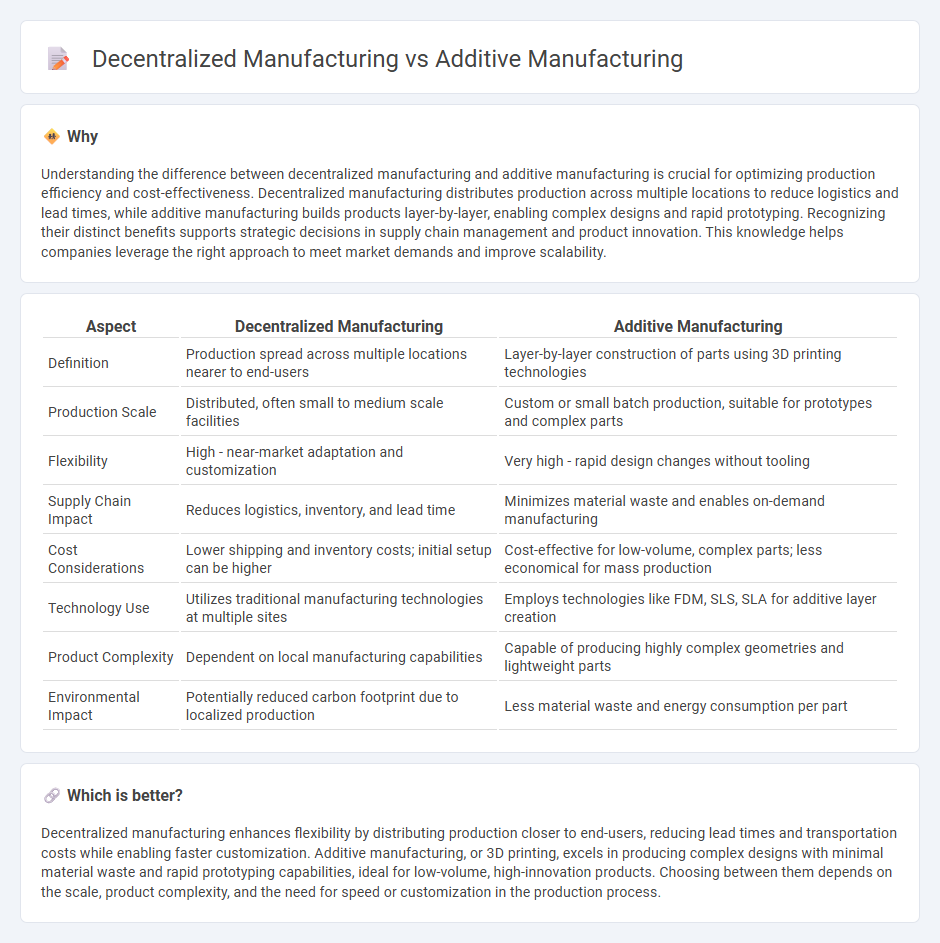

Understanding the difference between decentralized manufacturing and additive manufacturing is crucial for optimizing production efficiency and cost-effectiveness. Decentralized manufacturing distributes production across multiple locations to reduce logistics and lead times, while additive manufacturing builds products layer-by-layer, enabling complex designs and rapid prototyping. Recognizing their distinct benefits supports strategic decisions in supply chain management and product innovation. This knowledge helps companies leverage the right approach to meet market demands and improve scalability.

Comparison Table

| Aspect | Decentralized Manufacturing | Additive Manufacturing |

|---|---|---|

| Definition | Production spread across multiple locations nearer to end-users | Layer-by-layer construction of parts using 3D printing technologies |

| Production Scale | Distributed, often small to medium scale facilities | Custom or small batch production, suitable for prototypes and complex parts |

| Flexibility | High - near-market adaptation and customization | Very high - rapid design changes without tooling |

| Supply Chain Impact | Reduces logistics, inventory, and lead time | Minimizes material waste and enables on-demand manufacturing |

| Cost Considerations | Lower shipping and inventory costs; initial setup can be higher | Cost-effective for low-volume, complex parts; less economical for mass production |

| Technology Use | Utilizes traditional manufacturing technologies at multiple sites | Employs technologies like FDM, SLS, SLA for additive layer creation |

| Product Complexity | Dependent on local manufacturing capabilities | Capable of producing highly complex geometries and lightweight parts |

| Environmental Impact | Potentially reduced carbon footprint due to localized production | Less material waste and energy consumption per part |

Which is better?

Decentralized manufacturing enhances flexibility by distributing production closer to end-users, reducing lead times and transportation costs while enabling faster customization. Additive manufacturing, or 3D printing, excels in producing complex designs with minimal material waste and rapid prototyping capabilities, ideal for low-volume, high-innovation products. Choosing between them depends on the scale, product complexity, and the need for speed or customization in the production process.

Connection

Decentralized manufacturing leverages additive manufacturing by enabling production closer to the point of consumption, reducing supply chain complexities and lead times. Additive manufacturing's digital design files can be distributed globally, allowing decentralized facilities to produce customized parts on-demand, increasing flexibility and responsiveness. This synergy enhances efficiency, lowers transportation costs, and supports localized production strategies in various industries.

Key Terms

Additive Manufacturing:

Additive manufacturing, also known as 3D printing, builds objects layer by layer using digital models, enabling high customization and rapid prototyping without extensive tooling costs. This technology supports lightweight designs, complex geometries, and on-demand production, making it ideal for industries like aerospace, healthcare, and automotive. Explore how additive manufacturing transforms production processes and drives innovation in modern manufacturing.

3D Printing

Additive manufacturing, commonly known as 3D printing, builds objects layer by layer from digital models, enabling highly customizable and complex designs with minimal material waste. Decentralized manufacturing leverages 3D printing to distribute production closer to the point of use, reducing lead times and logistics costs while enhancing supply chain resilience. Explore how combining additive manufacturing with decentralized strategies transforms industries by boosting flexibility and local responsiveness.

Layer-by-Layer Fabrication

Additive manufacturing utilizes layer-by-layer fabrication to create complex and precise components directly from digital models, enabling customization and material efficiency. Decentralized manufacturing leverages this technology locally to reduce lead times, lower transportation costs, and increase responsiveness to demand fluctuations. Explore how the synergy between additive manufacturing and decentralized production transforms modern supply chains.

Source and External Links

Additive manufacturing, explained - Additive manufacturing is the process of creating objects layer by layer, typically via 3D printing, used initially for prototyping and now for functional products in industries like aerospace and engineering by building directly from digital designs using various materials including polymers and metals.

Additive manufacturing | NIST - Additive manufacturing (3D printing) fabricates 3D products layer-by-layer from digital designs, enabling complex, customized structures with reduced waste, commonly using powders or wires melted by lasers, with applications spanning aerospace to medical implants.

The 7 categories of Additive Manufacturing - The ASTM F42 standard classifies additive manufacturing into seven categories based on process and materials, including vat photopolymerization, material jetting, and binder jetting, reflecting the diverse technologies beyond just 3D printing.

dowidth.com

dowidth.com