Process mining leverages data from manufacturing execution systems to analyze and optimize production workflows, identifying bottlenecks and inefficiencies in real-time. Predictive maintenance uses sensor data and machine learning algorithms to forecast equipment failures, reducing downtime and maintenance costs. Explore how these technologies enhance manufacturing efficiency and reliability to learn more.

Why it is important

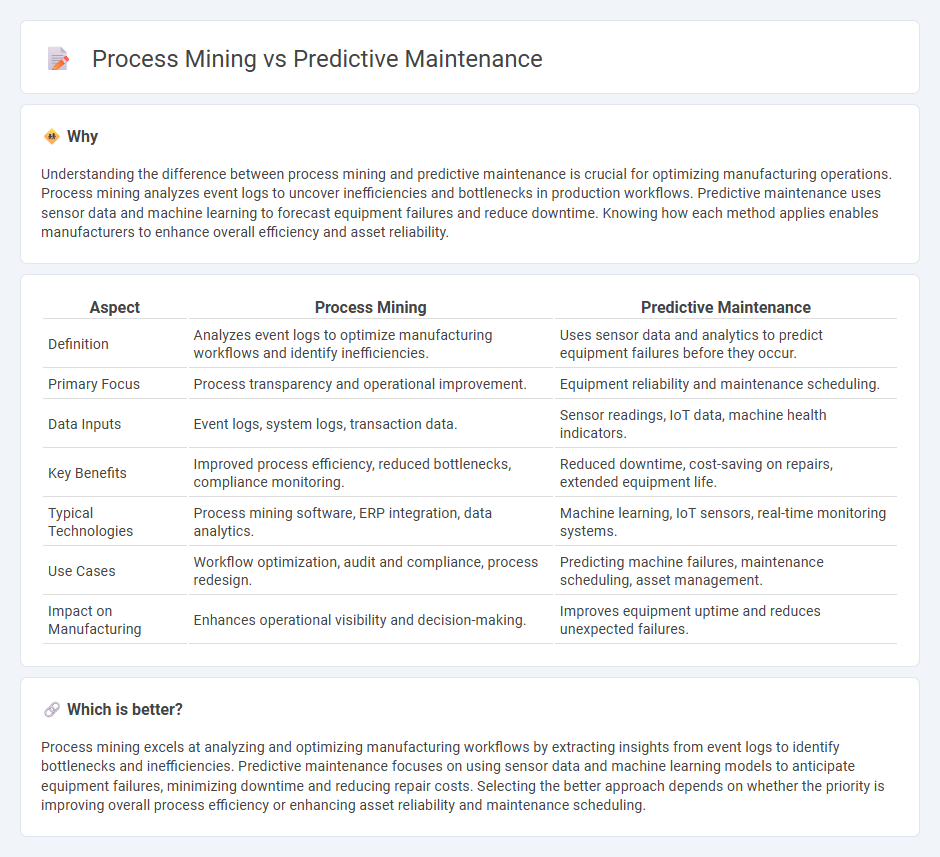

Understanding the difference between process mining and predictive maintenance is crucial for optimizing manufacturing operations. Process mining analyzes event logs to uncover inefficiencies and bottlenecks in production workflows. Predictive maintenance uses sensor data and machine learning to forecast equipment failures and reduce downtime. Knowing how each method applies enables manufacturers to enhance overall efficiency and asset reliability.

Comparison Table

| Aspect | Process Mining | Predictive Maintenance |

|---|---|---|

| Definition | Analyzes event logs to optimize manufacturing workflows and identify inefficiencies. | Uses sensor data and analytics to predict equipment failures before they occur. |

| Primary Focus | Process transparency and operational improvement. | Equipment reliability and maintenance scheduling. |

| Data Inputs | Event logs, system logs, transaction data. | Sensor readings, IoT data, machine health indicators. |

| Key Benefits | Improved process efficiency, reduced bottlenecks, compliance monitoring. | Reduced downtime, cost-saving on repairs, extended equipment life. |

| Typical Technologies | Process mining software, ERP integration, data analytics. | Machine learning, IoT sensors, real-time monitoring systems. |

| Use Cases | Workflow optimization, audit and compliance, process redesign. | Predicting machine failures, maintenance scheduling, asset management. |

| Impact on Manufacturing | Enhances operational visibility and decision-making. | Improves equipment uptime and reduces unexpected failures. |

Which is better?

Process mining excels at analyzing and optimizing manufacturing workflows by extracting insights from event logs to identify bottlenecks and inefficiencies. Predictive maintenance focuses on using sensor data and machine learning models to anticipate equipment failures, minimizing downtime and reducing repair costs. Selecting the better approach depends on whether the priority is improving overall process efficiency or enhancing asset reliability and maintenance scheduling.

Connection

Process mining extracts valuable insights from manufacturing event logs to identify inefficiencies and anomalies in production workflows. Predictive maintenance leverages these insights alongside real-time sensor data and machine learning algorithms to forecast equipment failures before they occur. Integrating process mining with predictive maintenance enhances operational efficiency by enabling proactive interventions, reducing downtime, and optimizing asset utilization.

Key Terms

**Predictive Maintenance:**

Predictive maintenance leverages sensor data, machine learning algorithms, and real-time monitoring to forecast equipment failures before they occur, reducing downtime and maintenance costs. By analyzing historical and operational data, it optimizes maintenance schedules, enhances asset longevity, and improves overall operational efficiency. Explore how predictive maintenance can transform your industrial operations and drive smarter maintenance strategies.

Condition Monitoring

Predictive maintenance leverages real-time sensor data and machine learning algorithms to anticipate equipment failures by continuously monitoring conditions such as vibration, temperature, and pressure. Process mining analyzes event logs from IT systems to uncover inefficiencies and bottlenecks in workflows, but it does not directly monitor physical equipment conditions. Discover how integrating condition monitoring with process mining enhances operational reliability and reduces unplanned downtime.

Failure Prediction

Predictive maintenance leverages sensor data and machine learning algorithms to anticipate equipment failures and schedule timely interventions, reducing downtime and maintenance costs. Process mining analyzes event logs to identify process inefficiencies and deviations that may cause failures, providing insights into underlying operational patterns. Explore more to understand how combining predictive maintenance with process mining enhances failure prediction accuracy.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses sensor data and machine learning to monitor equipment health in real time, predicting failures before they occur to optimize maintenance and reduce costs and downtime.

Predictive maintenance - Wikipedia - Predictive maintenance estimates when maintenance should be performed by assessing equipment condition to prevent unexpected failures and enable better planning, increasing availability and safety.

The Definitive Guide to Predictive Maintenance - FMX - Predictive maintenance leverages IoT sensors and real-time data analytics to detect early signs of equipment degradation, alerting teams to perform maintenance before breakdowns.

dowidth.com

dowidth.com