Remanufacturing involves restoring used products to like-new condition through disassembly, cleaning, repair, and replacement of components, significantly reducing waste and resource consumption. Additive manufacturing, also known as 3D printing, builds parts layer-by-layer from digital models, enabling complex geometries and rapid prototyping with minimal material use. Discover the key differences and benefits of remanufacturing versus additive manufacturing to optimize your production strategy.

Why it is important

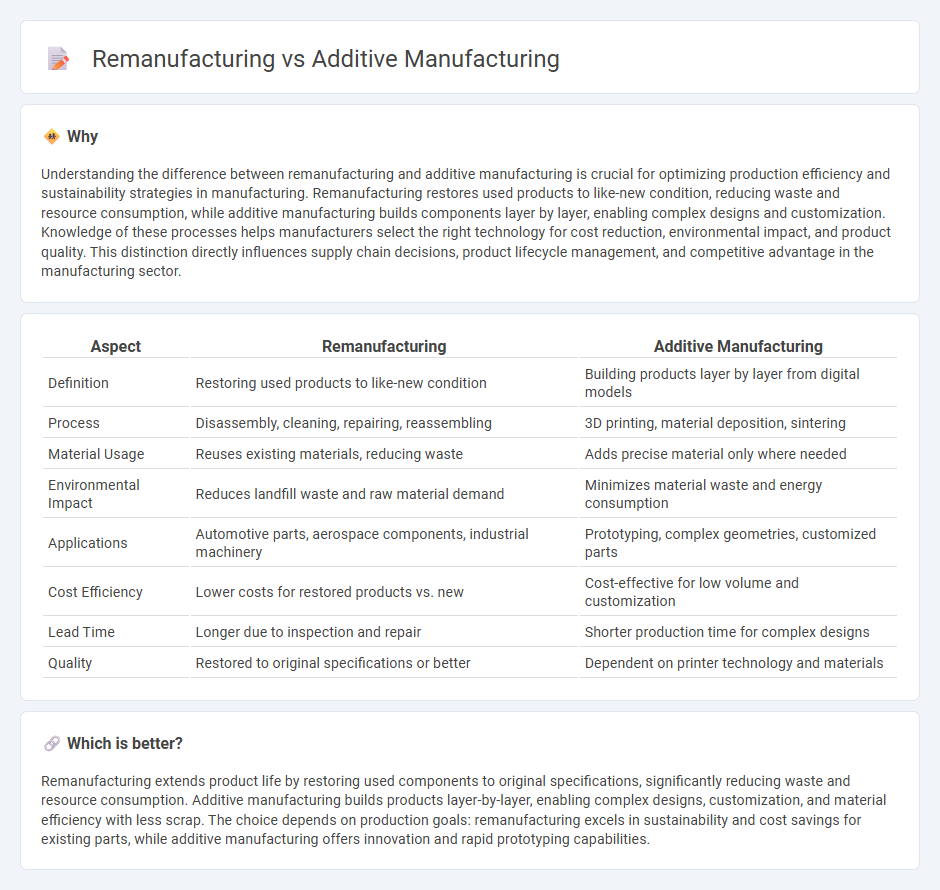

Understanding the difference between remanufacturing and additive manufacturing is crucial for optimizing production efficiency and sustainability strategies in manufacturing. Remanufacturing restores used products to like-new condition, reducing waste and resource consumption, while additive manufacturing builds components layer by layer, enabling complex designs and customization. Knowledge of these processes helps manufacturers select the right technology for cost reduction, environmental impact, and product quality. This distinction directly influences supply chain decisions, product lifecycle management, and competitive advantage in the manufacturing sector.

Comparison Table

| Aspect | Remanufacturing | Additive Manufacturing |

|---|---|---|

| Definition | Restoring used products to like-new condition | Building products layer by layer from digital models |

| Process | Disassembly, cleaning, repairing, reassembling | 3D printing, material deposition, sintering |

| Material Usage | Reuses existing materials, reducing waste | Adds precise material only where needed |

| Environmental Impact | Reduces landfill waste and raw material demand | Minimizes material waste and energy consumption |

| Applications | Automotive parts, aerospace components, industrial machinery | Prototyping, complex geometries, customized parts |

| Cost Efficiency | Lower costs for restored products vs. new | Cost-effective for low volume and customization |

| Lead Time | Longer due to inspection and repair | Shorter production time for complex designs |

| Quality | Restored to original specifications or better | Dependent on printer technology and materials |

Which is better?

Remanufacturing extends product life by restoring used components to original specifications, significantly reducing waste and resource consumption. Additive manufacturing builds products layer-by-layer, enabling complex designs, customization, and material efficiency with less scrap. The choice depends on production goals: remanufacturing excels in sustainability and cost savings for existing parts, while additive manufacturing offers innovation and rapid prototyping capabilities.

Connection

Remanufacturing and additive manufacturing both contribute to sustainable production by extending product life cycles and reducing waste. Remanufacturing restores used components to like-new condition, while additive manufacturing builds parts layer-by-layer, enabling precise repairs and customization. Integrating these technologies enhances resource efficiency and supports circular economy goals in manufacturing.

Key Terms

Layer-by-layer construction (Additive Manufacturing)

Layer-by-layer construction in additive manufacturing enables precise fabrication of complex geometries by depositing material sequentially, which contrasts with remanufacturing that primarily involves refurbishing or restoring existing components. This method reduces material waste and allows for customized production at scale, making it ideal for industries such as aerospace, automotive, and healthcare. Explore the advantages and applications of additive manufacturing techniques to understand its transformative impact on modern manufacturing.

Component restoration (Remanufacturing)

Component restoration in remanufacturing involves disassembling, cleaning, repairing, and reassembling used parts to meet original specifications, ensuring high performance and extended lifecycle. Additive manufacturing, while capable of creating new components from raw materials, often focuses on producing complex geometries rather than restoring worn parts. Explore detailed comparisons to understand how remanufacturing optimizes resource efficiency and sustainability in industrial applications.

Material feedstock (Additive Manufacturing)

Additive manufacturing employs layer-by-layer deposition of material feedstock such as thermoplastics, metals, and composites, allowing for precise control over material properties and reduced waste compared to traditional methods. Material feedstock in this process can be in the form of powders, filaments, or pellets, optimized for specific 3D printing technologies like selective laser sintering (SLS) or fused deposition modeling (FDM). Explore further to understand the impact of feedstock selection on performance, cost-efficiency, and sustainability in additive manufacturing.

Source and External Links

Additive manufacturing, explained | MIT Sloan - Additive manufacturing builds objects layer by layer from digital designs, opposite to subtractive manufacturing, and uses materials like polymers, metals, and ceramics to produce functional products, with applications growing since rapid prototyping in the 1980s.

Additive manufacturing | NIST - Additive manufacturing (3D printing) fabricates complex products by layering materials precisely as directed by digital designs, offering reduced waste and enabling applications such as customized biomedical implants and aerospace parts.

The 7 categories of Additive Manufacturing - Loughborough University - Additive manufacturing is classified into seven categories by ASTM standards, including VAT photopolymerisation, material jetting, and binder jetting, which differ primarily in materials and layer-building methods.

dowidth.com

dowidth.com