Industrial metaverse integrates immersive digital twins with real-time data to optimize manufacturing workflows, enabling enhanced visualization and remote collaboration. Predictive maintenance utilizes advanced sensors and AI-driven analytics to anticipate equipment failures, reducing downtime and maintenance costs. Discover how these technologies transform manufacturing efficiency and reliability.

Why it is important

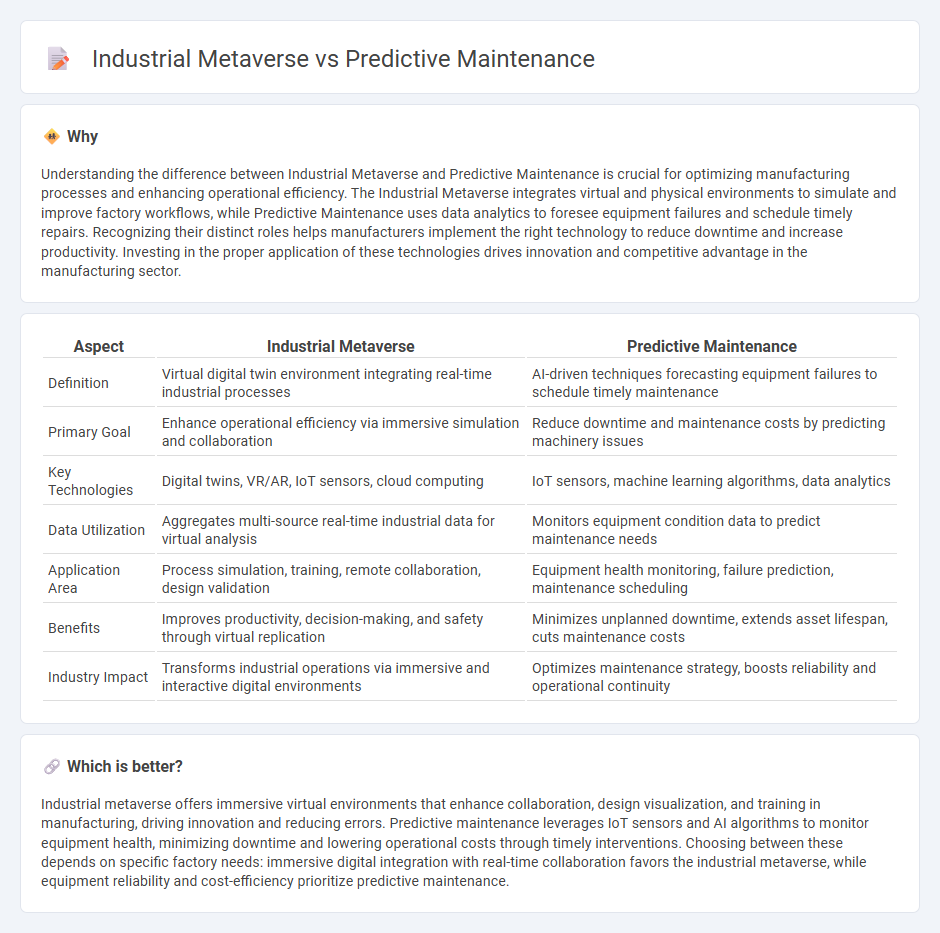

Understanding the difference between Industrial Metaverse and Predictive Maintenance is crucial for optimizing manufacturing processes and enhancing operational efficiency. The Industrial Metaverse integrates virtual and physical environments to simulate and improve factory workflows, while Predictive Maintenance uses data analytics to foresee equipment failures and schedule timely repairs. Recognizing their distinct roles helps manufacturers implement the right technology to reduce downtime and increase productivity. Investing in the proper application of these technologies drives innovation and competitive advantage in the manufacturing sector.

Comparison Table

| Aspect | Industrial Metaverse | Predictive Maintenance |

|---|---|---|

| Definition | Virtual digital twin environment integrating real-time industrial processes | AI-driven techniques forecasting equipment failures to schedule timely maintenance |

| Primary Goal | Enhance operational efficiency via immersive simulation and collaboration | Reduce downtime and maintenance costs by predicting machinery issues |

| Key Technologies | Digital twins, VR/AR, IoT sensors, cloud computing | IoT sensors, machine learning algorithms, data analytics |

| Data Utilization | Aggregates multi-source real-time industrial data for virtual analysis | Monitors equipment condition data to predict maintenance needs |

| Application Area | Process simulation, training, remote collaboration, design validation | Equipment health monitoring, failure prediction, maintenance scheduling |

| Benefits | Improves productivity, decision-making, and safety through virtual replication | Minimizes unplanned downtime, extends asset lifespan, cuts maintenance costs |

| Industry Impact | Transforms industrial operations via immersive and interactive digital environments | Optimizes maintenance strategy, boosts reliability and operational continuity |

Which is better?

Industrial metaverse offers immersive virtual environments that enhance collaboration, design visualization, and training in manufacturing, driving innovation and reducing errors. Predictive maintenance leverages IoT sensors and AI algorithms to monitor equipment health, minimizing downtime and lowering operational costs through timely interventions. Choosing between these depends on specific factory needs: immersive digital integration with real-time collaboration favors the industrial metaverse, while equipment reliability and cost-efficiency prioritize predictive maintenance.

Connection

The Industrial Metaverse integrates digital twins and IoT sensors to create immersive, real-time simulations of manufacturing processes, enabling advanced predictive maintenance strategies. Predictive maintenance leverages AI-driven data analytics within this virtual environment to foresee equipment failures and optimize maintenance schedules, reducing downtime and operational costs. This synergy enhances manufacturing efficiency and extends machinery lifespan by transforming raw sensor data into actionable insights through immersive digital platforms.

Key Terms

Predictive Maintenance:

Predictive Maintenance leverages advanced IoT sensors and AI algorithms to monitor equipment health, forecast failures, and optimize maintenance schedules, significantly reducing downtime and operational costs in manufacturing environments. Industrial metaverse integrates immersive digital twins and virtual collaboration platforms, but Predictive Maintenance remains critical for real-time asset performance and predictive analytics. Explore how cutting-edge predictive maintenance technologies transform industrial efficiency and reliability.

Condition Monitoring

Condition monitoring involves continuous data collection from machinery sensors to detect anomalies and predict equipment failures, a core aspect of predictive maintenance aimed at minimizing downtime and reducing maintenance costs. The industrial metaverse enhances this process by integrating real-time digital twins and immersive visualization, enabling more effective remote monitoring and proactive decision-making within virtual environments. Explore how combining predictive maintenance with the industrial metaverse transforms condition monitoring for smarter, more efficient industrial operations.

Failure Prediction

Predictive maintenance leverages IoT sensors and machine learning to analyze equipment data, enabling early failure detection and minimizing downtime in industrial settings. The industrial metaverse integrates digital twins and augmented reality to provide immersive visualization and simulation, enhancing failure prediction and maintenance decision-making. Explore how combining these technologies can revolutionize failure prediction and operational efficiency.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance helps predict potential equipment failures by analyzing real-time data, optimizing performance, and reducing unnecessary maintenance costs.

Predictive Maintenance - Wikipedia - Predictive maintenance uses condition-based monitoring to determine when maintenance should be performed, reducing unexpected failures and increasing equipment lifespan.

Predictive Maintenance: An Easy Guide | SafetyCulture - Predictive maintenance involves collecting data from IoT devices, using machine learning to predict equipment failures, and scheduling maintenance accordingly to achieve operational excellence.

dowidth.com

dowidth.com