Manufacturing is rapidly evolving with concepts like Lights Out Factory and Industry 4.0 driving automation and efficiency. Lights Out Factory focuses on fully autonomous production with minimal human intervention, leveraging robotics and AI to operate continuously. Explore how these innovations are transforming modern factory operations and shaping the future of manufacturing.

Why it is important

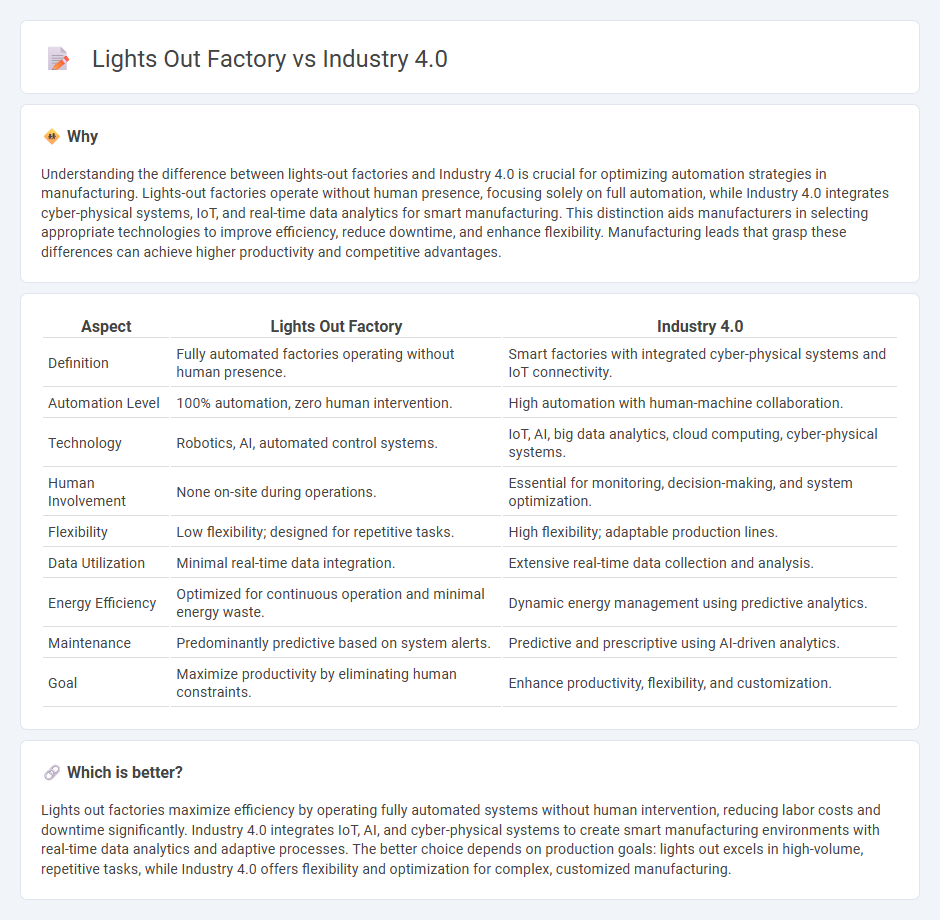

Understanding the difference between lights-out factories and Industry 4.0 is crucial for optimizing automation strategies in manufacturing. Lights-out factories operate without human presence, focusing solely on full automation, while Industry 4.0 integrates cyber-physical systems, IoT, and real-time data analytics for smart manufacturing. This distinction aids manufacturers in selecting appropriate technologies to improve efficiency, reduce downtime, and enhance flexibility. Manufacturing leads that grasp these differences can achieve higher productivity and competitive advantages.

Comparison Table

| Aspect | Lights Out Factory | Industry 4.0 |

|---|---|---|

| Definition | Fully automated factories operating without human presence. | Smart factories with integrated cyber-physical systems and IoT connectivity. |

| Automation Level | 100% automation, zero human intervention. | High automation with human-machine collaboration. |

| Technology | Robotics, AI, automated control systems. | IoT, AI, big data analytics, cloud computing, cyber-physical systems. |

| Human Involvement | None on-site during operations. | Essential for monitoring, decision-making, and system optimization. |

| Flexibility | Low flexibility; designed for repetitive tasks. | High flexibility; adaptable production lines. |

| Data Utilization | Minimal real-time data integration. | Extensive real-time data collection and analysis. |

| Energy Efficiency | Optimized for continuous operation and minimal energy waste. | Dynamic energy management using predictive analytics. |

| Maintenance | Predominantly predictive based on system alerts. | Predictive and prescriptive using AI-driven analytics. |

| Goal | Maximize productivity by eliminating human constraints. | Enhance productivity, flexibility, and customization. |

Which is better?

Lights out factories maximize efficiency by operating fully automated systems without human intervention, reducing labor costs and downtime significantly. Industry 4.0 integrates IoT, AI, and cyber-physical systems to create smart manufacturing environments with real-time data analytics and adaptive processes. The better choice depends on production goals: lights out excels in high-volume, repetitive tasks, while Industry 4.0 offers flexibility and optimization for complex, customized manufacturing.

Connection

Lights out factories exemplify Industry 4.0 by fully integrating automation, IoT sensors, and AI-driven systems to operate without human intervention. Industry 4.0 technologies enable real-time data analytics, predictive maintenance, and seamless machine-to-machine communication critical for autonomous manufacturing processes. This connectivity results in optimized production efficiency, reduced operational costs, and improved product quality.

Key Terms

Industry 4.0:

Industry 4.0 integrates cyber-physical systems, IoT, and AI to create smart factories that enable real-time data exchange and autonomous decision-making. This approach enhances production efficiency, predictive maintenance, and supply chain optimization, driving competitive advantage. Discover how Industry 4.0 transforms manufacturing by exploring its key technologies and benefits.

Cyber-Physical Systems

Industry 4.0 integrates Cyber-Physical Systems (CPS) to enable smart manufacturing through interconnected machines, real-time data analytics, and adaptive automation. Lights Out Factories emphasize fully autonomous operations with minimal to no human intervention, relying extensively on CPS for seamless machine communication and control. Explore how CPS innovations are driving the evolution from traditional smart factories to fully automated lights out environments.

Industrial Internet of Things (IIoT)

Industry 4.0 revolutionizes manufacturing through interconnected cyber-physical systems, emphasizing real-time data exchange and smart automation powered by the Industrial Internet of Things (IIoT). Lights out factories represent fully automated facilities operating without human presence, leveraging IIoT sensors and AI to enhance efficiency and reduce operational costs. Explore how IIoT drives innovation and shapes the future of smart manufacturing.

Source and External Links

Industry 4.0 vs 5.0: What's the Difference? - Industry 4.0, also called the Fourth Industrial Revolution, involves the rise of digital industrial technology like cyber-physical systems to create smart, integrated manufacturing with data-driven, versatile production.

What is Industry 4.0? - Industry 4.0 refers to smart manufacturing using IoT, cloud computing, AI, and robotics to enable real-time decision making, increased automation, predictive maintenance, and overall enhanced productivity and flexibility.

What is industry 4.0 and the Fourth Industrial Revolution? - Industry 4.0 transforms industries by leveraging connectivity, advanced analytics, and automation, with sectors like manufacturing and transportation having the greatest potential for automation and digitization.

dowidth.com

dowidth.com