The Industrial Internet integrates advanced sensors, data analytics, and connectivity to optimize manufacturing processes in real-time, enhancing predictive maintenance and operational efficiency. Manufacturing Execution Systems (MES) focus on tracking and managing production workflows, ensuring quality control and compliance with industry standards. Explore how combining Industrial Internet technologies with MES can revolutionize manufacturing operations.

Why it is important

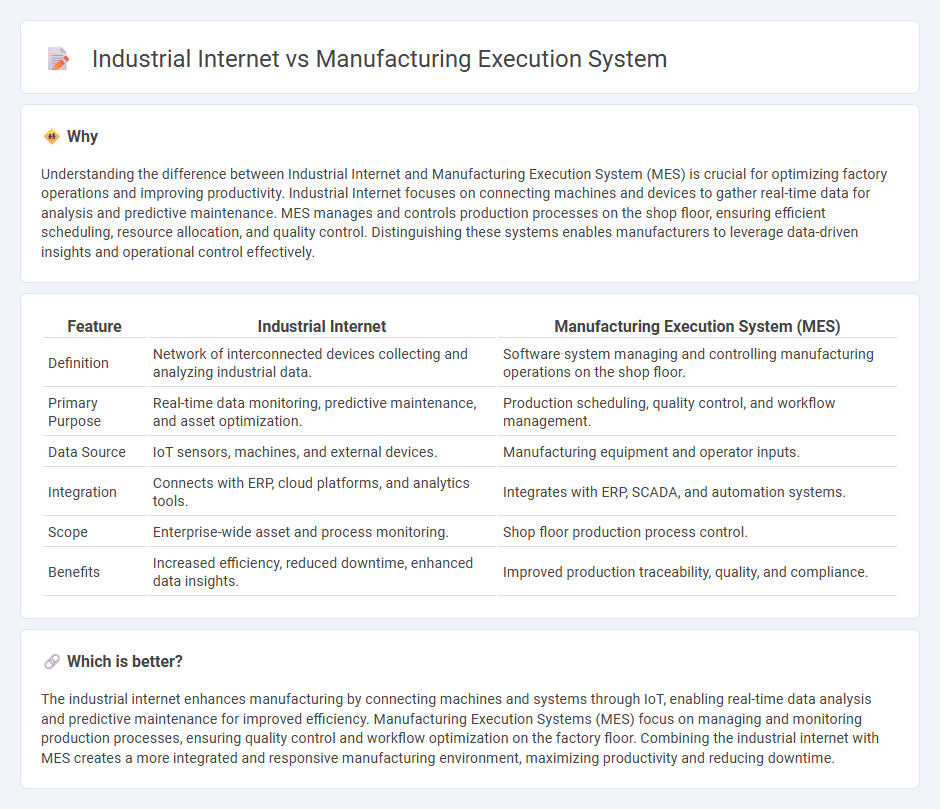

Understanding the difference between Industrial Internet and Manufacturing Execution System (MES) is crucial for optimizing factory operations and improving productivity. Industrial Internet focuses on connecting machines and devices to gather real-time data for analysis and predictive maintenance. MES manages and controls production processes on the shop floor, ensuring efficient scheduling, resource allocation, and quality control. Distinguishing these systems enables manufacturers to leverage data-driven insights and operational control effectively.

Comparison Table

| Feature | Industrial Internet | Manufacturing Execution System (MES) |

|---|---|---|

| Definition | Network of interconnected devices collecting and analyzing industrial data. | Software system managing and controlling manufacturing operations on the shop floor. |

| Primary Purpose | Real-time data monitoring, predictive maintenance, and asset optimization. | Production scheduling, quality control, and workflow management. |

| Data Source | IoT sensors, machines, and external devices. | Manufacturing equipment and operator inputs. |

| Integration | Connects with ERP, cloud platforms, and analytics tools. | Integrates with ERP, SCADA, and automation systems. |

| Scope | Enterprise-wide asset and process monitoring. | Shop floor production process control. |

| Benefits | Increased efficiency, reduced downtime, enhanced data insights. | Improved production traceability, quality, and compliance. |

Which is better?

The industrial internet enhances manufacturing by connecting machines and systems through IoT, enabling real-time data analysis and predictive maintenance for improved efficiency. Manufacturing Execution Systems (MES) focus on managing and monitoring production processes, ensuring quality control and workflow optimization on the factory floor. Combining the industrial internet with MES creates a more integrated and responsive manufacturing environment, maximizing productivity and reducing downtime.

Connection

The Industrial Internet integrates smart sensors, machines, and data analytics to enhance manufacturing processes, while a Manufacturing Execution System (MES) manages and monitors real-time production activities on the factory floor. MES collects data from Industrial Internet-connected devices to optimize workflow, improve quality control, and enable predictive maintenance. This synergy accelerates decision-making, reduces downtime, and increases overall operational efficiency in manufacturing environments.

Key Terms

Real-time Monitoring

Manufacturing Execution Systems (MES) provide real-time monitoring by tracking production processes, machine performance, and quality control data directly on the shop floor, ensuring operational efficiency and compliance. The Industrial Internet leverages IoT sensors and cloud connectivity to collect and analyze vast amounts of real-time data across multiple equipment and sites, enhancing predictive maintenance and decision-making. Explore how integrating MES with Industrial Internet technologies can optimize manufacturing transparency and performance.

Data Integration

Manufacturing Execution Systems (MES) centralize production data by capturing real-time shop floor activities, while Industrial Internet platforms integrate diverse sensor and machine data across connected assets for scalable analytics. MES emphasizes structured, process-specific data integration to optimize workflow and quality control, whereas Industrial Internet solutions prioritize broad data interoperability and advanced analytics for predictive maintenance and operational efficiency. Explore deeper insights into how data integration drives digital transformation in manufacturing environments.

Connectivity

Manufacturing Execution Systems (MES) provide real-time production monitoring and control, enabling seamless data exchange across shop floor devices to enhance operational efficiency. The Industrial Internet integrates advanced sensor networks and IoT technologies, fostering connectivity between machines, analytics platforms, and cloud infrastructure to drive intelligent decision-making. Explore in-depth comparisons and connectivity advantages of MES versus Industrial Internet to optimize manufacturing processes.

Source and External Links

Manufacturing execution system - Wikipedia - Manufacturing execution systems (MES) are computerized systems that track and document the transformation of raw materials into finished goods, providing real-time monitoring and control of production processes to optimize output and quality while managing resources like materials, labor, and equipment.

What is a Manufacturing Execution System (MES)? - IBM - MES is a software solution that monitors and controls shop floor production, acting as a bridge between ERP systems and actual manufacturing operations, providing real-time visibility to improve production efficiency, quality assurance, compliance, and resource management.

Best Manufacturing Execution Systems Reviews 2025 - Gartner - Manufacturing execution systems are production-oriented software that manage, monitor, and synchronize real-time physical manufacturing processes, coordinating work orders with production scheduling and enterprise systems, while supporting traceability and process performance feedback.

dowidth.com

dowidth.com