Machine vision systems enhance manufacturing quality control by providing automated, real-time inspections that detect defects and ensure precise assembly. End-of-line testing validates product functionality at the final production stage, confirming performance standards before shipment. Explore how integrating machine vision with end-of-line testing can optimize manufacturing efficiency and reduce defect rates.

Why it is important

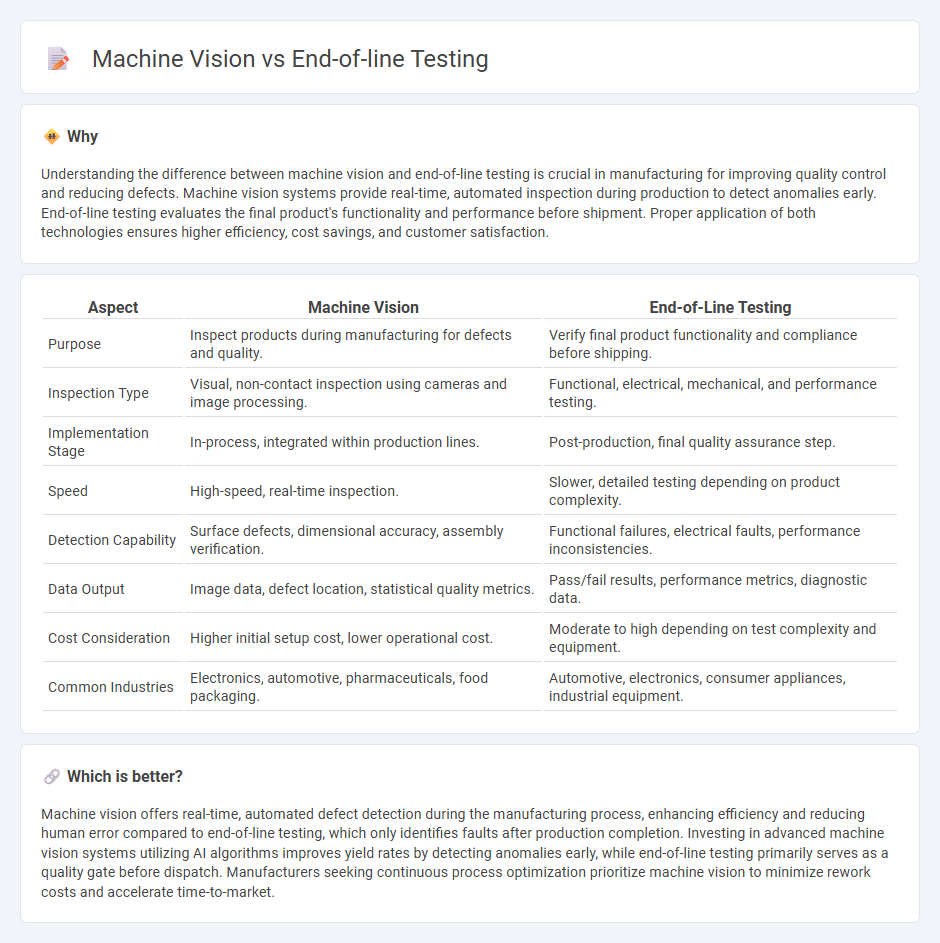

Understanding the difference between machine vision and end-of-line testing is crucial in manufacturing for improving quality control and reducing defects. Machine vision systems provide real-time, automated inspection during production to detect anomalies early. End-of-line testing evaluates the final product's functionality and performance before shipment. Proper application of both technologies ensures higher efficiency, cost savings, and customer satisfaction.

Comparison Table

| Aspect | Machine Vision | End-of-Line Testing |

|---|---|---|

| Purpose | Inspect products during manufacturing for defects and quality. | Verify final product functionality and compliance before shipping. |

| Inspection Type | Visual, non-contact inspection using cameras and image processing. | Functional, electrical, mechanical, and performance testing. |

| Implementation Stage | In-process, integrated within production lines. | Post-production, final quality assurance step. |

| Speed | High-speed, real-time inspection. | Slower, detailed testing depending on product complexity. |

| Detection Capability | Surface defects, dimensional accuracy, assembly verification. | Functional failures, electrical faults, performance inconsistencies. |

| Data Output | Image data, defect location, statistical quality metrics. | Pass/fail results, performance metrics, diagnostic data. |

| Cost Consideration | Higher initial setup cost, lower operational cost. | Moderate to high depending on test complexity and equipment. |

| Common Industries | Electronics, automotive, pharmaceuticals, food packaging. | Automotive, electronics, consumer appliances, industrial equipment. |

Which is better?

Machine vision offers real-time, automated defect detection during the manufacturing process, enhancing efficiency and reducing human error compared to end-of-line testing, which only identifies faults after production completion. Investing in advanced machine vision systems utilizing AI algorithms improves yield rates by detecting anomalies early, while end-of-line testing primarily serves as a quality gate before dispatch. Manufacturers seeking continuous process optimization prioritize machine vision to minimize rework costs and accelerate time-to-market.

Connection

Machine vision systems enhance end-of-line testing by providing precise, automated inspection of product quality and defect detection. These technologies utilize high-resolution cameras and advanced algorithms to identify irregularities, ensuring compliance with manufacturing standards before shipment. Integrating machine vision in end-of-line testing reduces human error, accelerates throughput, and improves overall production efficiency in manufacturing processes.

Key Terms

Functional Testing

End-of-line testing ensures product functionality by using sensors and manual checks to verify electronic and mechanical operations, emphasizing reliability in final-stage validation. Machine vision employs advanced cameras and AI algorithms to detect defects, alignment issues, and assembly errors, enhancing precision and reducing human error in functional testing. Explore how integrating both methods optimizes quality control and boosts manufacturing efficiency.

Defect Detection

End-of-line testing ensures product quality by physically verifying each unit for defects, while machine vision leverages advanced cameras and AI algorithms to detect surface anomalies automatically, increasing inspection speed and accuracy. Machine vision systems excel in identifying subtle defects such as scratches, misalignments, and contamination that may be missed during manual testing, leading to higher yield and reduced recall costs. Discover more about integrating machine vision with end-of-line testing to revolutionize defect detection.

Automated Inspection

End-of-line testing ensures product functionality by verifying electrical, mechanical, or software parameters at the final manufacturing stage, emphasizing accuracy and compliance. Machine vision uses advanced imaging and AI algorithms to detect surface defects, alignment issues, and assembly errors in real-time, enhancing quality control efficiency and reducing manual inspection costs. Explore the latest innovations in automated inspection technologies to optimize manufacturing quality assurance.

Source and External Links

End-of-line-Test (EOL Test) - ENGMATEC GmbH - End-of-line (EOL) testing is a final quality check performed at the production line's end to verify that products meet specifications and function properly before being packaged and shipped.

EOL Testing for Electronic Devices - EoL Test Stages and Testers - EOL testing for electronic devices is a critical step at the end of manufacturing that validates product performance, safety, and reliability, especially in industries like automotive where embedded systems must function flawlessly in final applications.

What is EOL, End of Line Testing? - Mustang Advanced Engineering - EOL testing is a functional quality assurance process at the final production stage, essential for catching defects, ensuring consistency, and reducing the risk of costly recalls or returns before products reach customers.

dowidth.com

dowidth.com