Human augmentation enhances workforce capabilities through advanced technologies like exoskeletons and neural interfaces, boosting productivity and safety on manufacturing floors. Supply chain optimization leverages AI, IoT, and real-time data analytics to streamline inventory management, reduce costs, and improve delivery times. Discover how these innovations are transforming manufacturing efficiency and competitiveness.

Why it is important

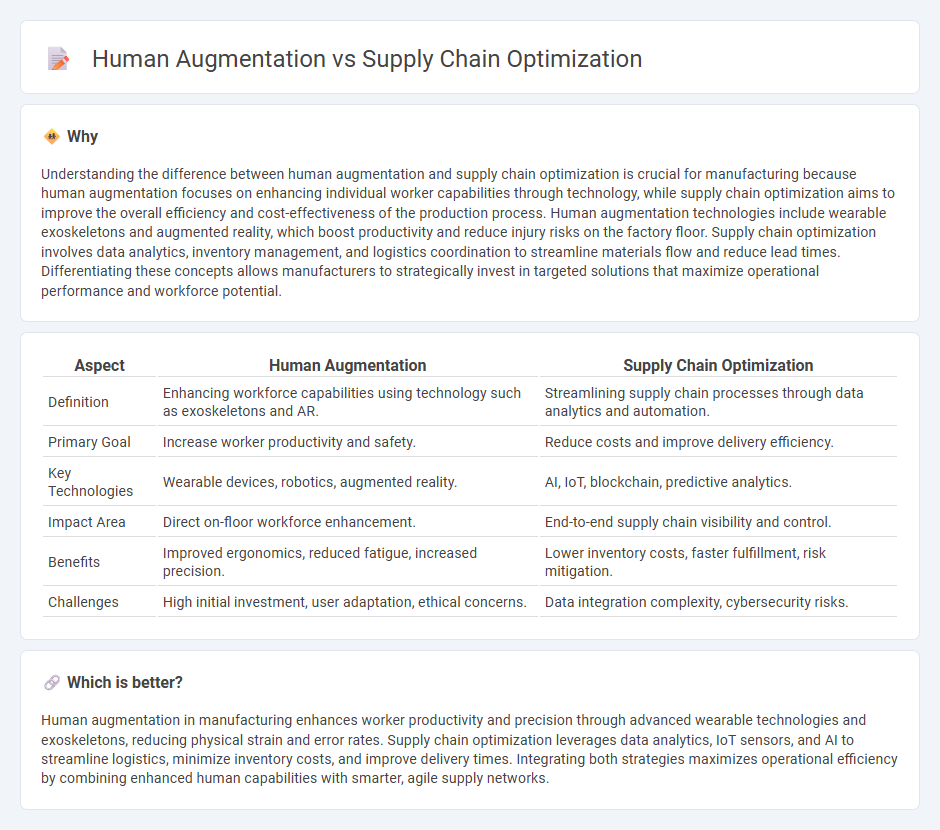

Understanding the difference between human augmentation and supply chain optimization is crucial for manufacturing because human augmentation focuses on enhancing individual worker capabilities through technology, while supply chain optimization aims to improve the overall efficiency and cost-effectiveness of the production process. Human augmentation technologies include wearable exoskeletons and augmented reality, which boost productivity and reduce injury risks on the factory floor. Supply chain optimization involves data analytics, inventory management, and logistics coordination to streamline materials flow and reduce lead times. Differentiating these concepts allows manufacturers to strategically invest in targeted solutions that maximize operational performance and workforce potential.

Comparison Table

| Aspect | Human Augmentation | Supply Chain Optimization |

|---|---|---|

| Definition | Enhancing workforce capabilities using technology such as exoskeletons and AR. | Streamlining supply chain processes through data analytics and automation. |

| Primary Goal | Increase worker productivity and safety. | Reduce costs and improve delivery efficiency. |

| Key Technologies | Wearable devices, robotics, augmented reality. | AI, IoT, blockchain, predictive analytics. |

| Impact Area | Direct on-floor workforce enhancement. | End-to-end supply chain visibility and control. |

| Benefits | Improved ergonomics, reduced fatigue, increased precision. | Lower inventory costs, faster fulfillment, risk mitigation. |

| Challenges | High initial investment, user adaptation, ethical concerns. | Data integration complexity, cybersecurity risks. |

Which is better?

Human augmentation in manufacturing enhances worker productivity and precision through advanced wearable technologies and exoskeletons, reducing physical strain and error rates. Supply chain optimization leverages data analytics, IoT sensors, and AI to streamline logistics, minimize inventory costs, and improve delivery times. Integrating both strategies maximizes operational efficiency by combining enhanced human capabilities with smarter, agile supply networks.

Connection

Human augmentation enhances workforce capabilities through advanced wearable technologies and AI-driven tools, increasing precision and efficiency in manufacturing processes. These improvements enable real-time data collection and decision-making that optimize supply chain management by predicting demand fluctuations and reducing bottlenecks. Integrating augmented human performance with supply chain analytics drives cost reduction, faster production cycles, and improved product quality across manufacturing operations.

Key Terms

**Supply Chain Optimization:**

Supply chain optimization leverages advanced analytics, artificial intelligence, and real-time data to streamline operations, reduce costs, and improve efficiency across procurement, inventory management, and logistics. Key technologies include predictive analytics, automation, and IoT-enabled tracking systems that enhance demand forecasting and minimize supply chain disruptions. Discover how integrating these innovations can transform your supply chain performance for competitive advantage.

Inventory Management

Supply chain optimization in inventory management leverages data analytics and automation to reduce stockouts, minimize holding costs, and improve order accuracy. Human augmentation introduces advanced wearable technology and AI-driven decision support systems that enhance workers' efficiency and real-time responsiveness in managing inventory tasks. Explore how combining these technologies transforms inventory management with precision and agility.

Demand Forecasting

Demand forecasting in supply chain optimization leverages advanced algorithms and big data analytics to predict customer demand patterns, enabling businesses to reduce inventory costs and improve delivery efficiency. Human augmentation enhances demand forecasting by integrating augmented intelligence tools that assist analysts in interpreting complex datasets and making more accurate predictions. Explore how combining these technologies can revolutionize demand forecasting accuracy and operational agility.

Source and External Links

The Ultimate Guide to Supply Chain Optimization - Order.co - Supply chain optimization improves production and distribution through techniques like assessing current SCM practices, improving planning, continuous negotiation, expanding analytics, and automation to increase efficiency and reduce costs.

What is Supply Chain Optimization? - Tibco - Supply chain optimization involves adjusting operations to reach peak efficiency by focusing on cost, inventory, and network optimization to enhance quality, reduce waste, and improve responsiveness.

What Is Supply Chain Optimization? - IBM - Supply chain optimization leverages technologies like AI, IoT, and blockchain to improve network design, deployment planning, and execution systems, ensuring efficient, profitable, and customer-responsive supply chains.

dowidth.com

dowidth.com