Human augmentation enhances worker capabilities through wearable devices and neural interfaces, increasing precision and reducing fatigue in manufacturing tasks. Collaborative robots (cobots) work alongside humans, automating repetitive processes and improving efficiency without fully replacing the workforce. Explore the latest advancements in manufacturing technology to understand how these innovations are shaping the future of production.

Why it is important

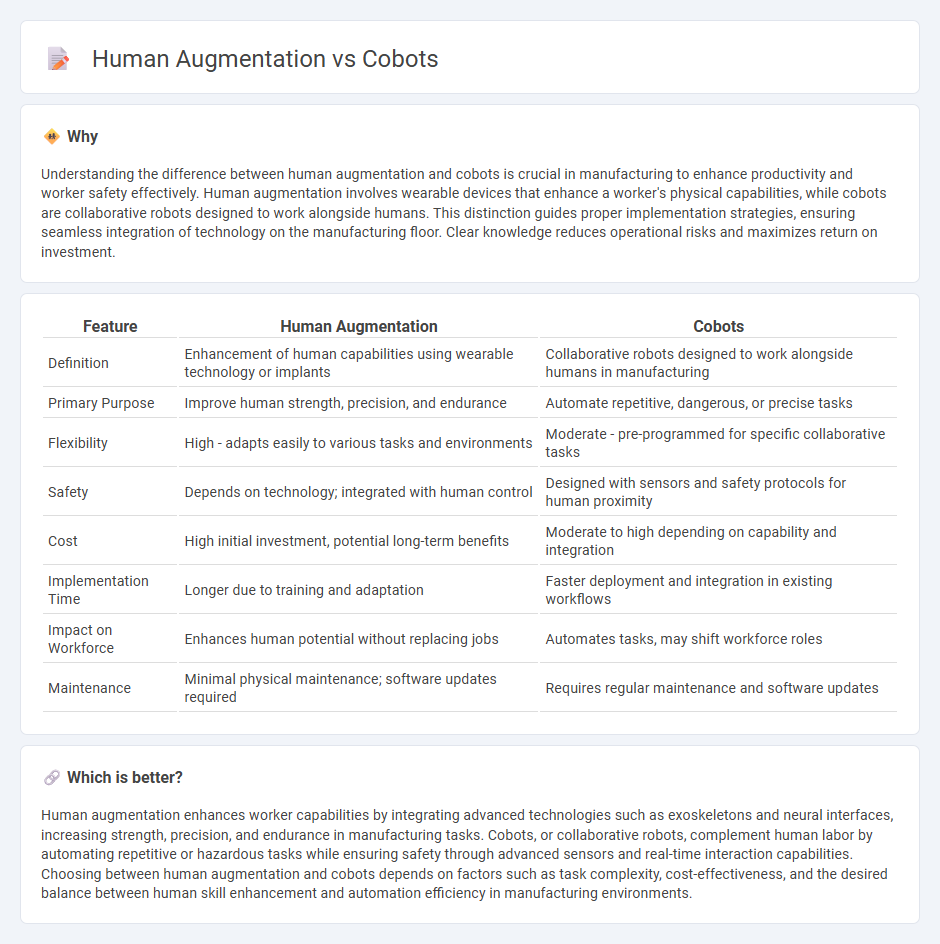

Understanding the difference between human augmentation and cobots is crucial in manufacturing to enhance productivity and worker safety effectively. Human augmentation involves wearable devices that enhance a worker's physical capabilities, while cobots are collaborative robots designed to work alongside humans. This distinction guides proper implementation strategies, ensuring seamless integration of technology on the manufacturing floor. Clear knowledge reduces operational risks and maximizes return on investment.

Comparison Table

| Feature | Human Augmentation | Cobots |

|---|---|---|

| Definition | Enhancement of human capabilities using wearable technology or implants | Collaborative robots designed to work alongside humans in manufacturing |

| Primary Purpose | Improve human strength, precision, and endurance | Automate repetitive, dangerous, or precise tasks |

| Flexibility | High - adapts easily to various tasks and environments | Moderate - pre-programmed for specific collaborative tasks |

| Safety | Depends on technology; integrated with human control | Designed with sensors and safety protocols for human proximity |

| Cost | High initial investment, potential long-term benefits | Moderate to high depending on capability and integration |

| Implementation Time | Longer due to training and adaptation | Faster deployment and integration in existing workflows |

| Impact on Workforce | Enhances human potential without replacing jobs | Automates tasks, may shift workforce roles |

| Maintenance | Minimal physical maintenance; software updates required | Requires regular maintenance and software updates |

Which is better?

Human augmentation enhances worker capabilities by integrating advanced technologies such as exoskeletons and neural interfaces, increasing strength, precision, and endurance in manufacturing tasks. Cobots, or collaborative robots, complement human labor by automating repetitive or hazardous tasks while ensuring safety through advanced sensors and real-time interaction capabilities. Choosing between human augmentation and cobots depends on factors such as task complexity, cost-effectiveness, and the desired balance between human skill enhancement and automation efficiency in manufacturing environments.

Connection

Human augmentation and cobots collaborate to enhance manufacturing efficiency by combining human dexterity with robotic precision. Augmented workers leverage wearable exoskeletons and augmented reality tools to reduce fatigue and improve task accuracy, while cobots assist with repetitive or hazardous tasks, fostering seamless human-robot interaction on the production floor. This synergy drives productivity gains, reduces workplace injuries, and supports adaptive manufacturing processes.

Key Terms

Collaborative Robots (Cobots)

Collaborative robots (cobots) are designed to work safely alongside humans, enhancing productivity by automating repetitive or hazardous tasks while allowing human workers to focus on complex decision-making. Unlike human augmentation, which involves enhancing human capabilities through wearable technology or implants, cobots provide external robotic assistance without altering human physiology. Explore how cobots are revolutionizing industries by combining human intelligence with robotic precision for seamless collaboration.

Exoskeletons

Exoskeletons serve as a prime example of human augmentation technology designed to enhance physical capabilities, providing support and strength to reduce injury risks in industrial and medical settings. Cobots, or collaborative robots, function alongside human workers to improve efficiency and safety without replacing human skills, often handling repetitive or precise tasks. Explore how exoskeletons and cobots uniquely contribute to workforce productivity and worker well-being by learning more about their applications and benefits.

Human-Robot Interaction

Cobots enhance human-robot interaction by working collaboratively alongside humans, improving safety and efficiency in tasks requiring precision and adaptability. Human augmentation involves wearable devices and exoskeletons that amplify workers' physical capabilities and cognitive performance, enabling more natural and intuitive control during complex operations. Explore the latest advancements in cobots and human augmentation to understand their impact on future workplaces.

Source and External Links

What is a cobot? | The ultimate collaborative robot guide - A cobot (collaborative robot) is a robot equipped with sensitive sensors that allow it to work safely alongside humans by entering safety mode if interrupted, enabling small and medium manufacturers to adopt automation economically and flexibly.

Why Cobots? - Universal Robots - Cobots are designed to share a workspace with humans, providing cost-effective, safe, and flexible automation solutions accessible to companies of all sizes, with Universal Robots having sold over 100,000 cobots globally.

Collaborative Robots - How Robots Work alongside Humans - Cobots are easy-to-program collaborative robots used in manufacturing and other industries for diverse tasks, complementing traditional industrial robots by offering safe human collaboration, adaptability, and expanding capabilities through AI and sensor technologies.

dowidth.com

dowidth.com