Industrial metaverse integrates advanced digital twins, augmented reality, and immersive simulations to create interactive virtual models that enhance manufacturing processes beyond the capabilities of Industry 4.0's focus on automation, IoT, and data analytics. By leveraging real-time data and AI-driven insights within a shared virtual environment, the industrial metaverse offers unprecedented collaboration, predictive maintenance, and optimization opportunities. Explore how merging these technologies is revolutionizing manufacturing efficiency and innovation.

Why it is important

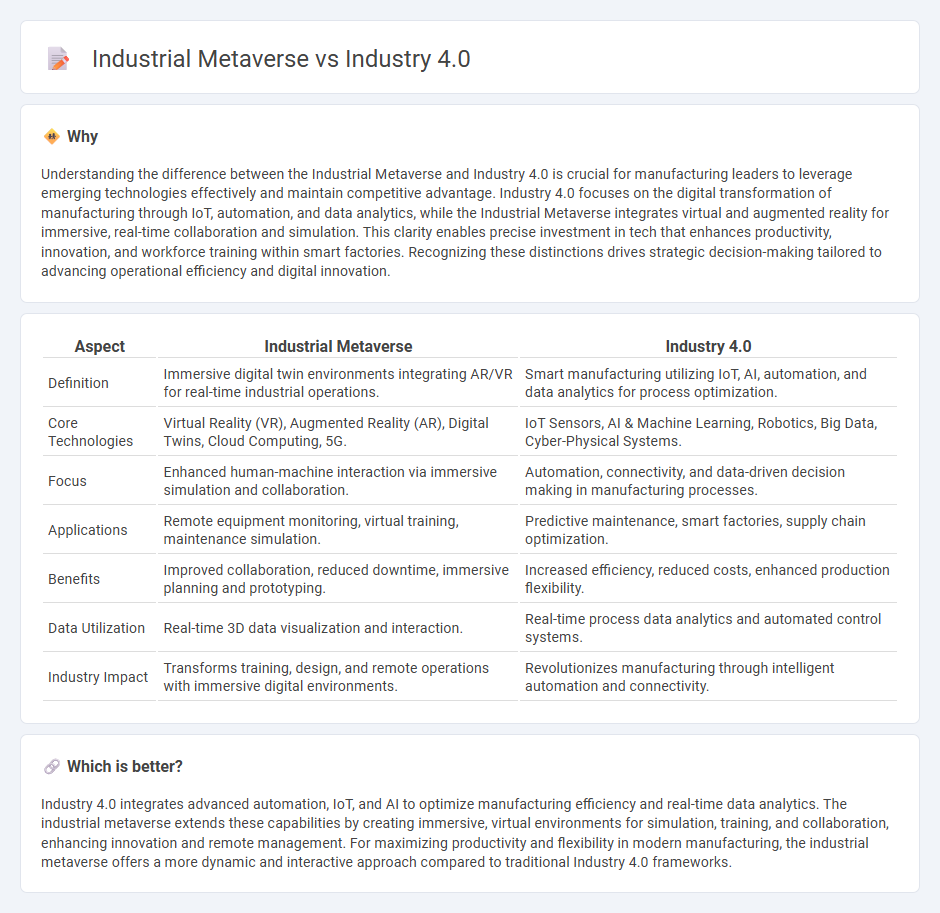

Understanding the difference between the Industrial Metaverse and Industry 4.0 is crucial for manufacturing leaders to leverage emerging technologies effectively and maintain competitive advantage. Industry 4.0 focuses on the digital transformation of manufacturing through IoT, automation, and data analytics, while the Industrial Metaverse integrates virtual and augmented reality for immersive, real-time collaboration and simulation. This clarity enables precise investment in tech that enhances productivity, innovation, and workforce training within smart factories. Recognizing these distinctions drives strategic decision-making tailored to advancing operational efficiency and digital innovation.

Comparison Table

| Aspect | Industrial Metaverse | Industry 4.0 |

|---|---|---|

| Definition | Immersive digital twin environments integrating AR/VR for real-time industrial operations. | Smart manufacturing utilizing IoT, AI, automation, and data analytics for process optimization. |

| Core Technologies | Virtual Reality (VR), Augmented Reality (AR), Digital Twins, Cloud Computing, 5G. | IoT Sensors, AI & Machine Learning, Robotics, Big Data, Cyber-Physical Systems. |

| Focus | Enhanced human-machine interaction via immersive simulation and collaboration. | Automation, connectivity, and data-driven decision making in manufacturing processes. |

| Applications | Remote equipment monitoring, virtual training, maintenance simulation. | Predictive maintenance, smart factories, supply chain optimization. |

| Benefits | Improved collaboration, reduced downtime, immersive planning and prototyping. | Increased efficiency, reduced costs, enhanced production flexibility. |

| Data Utilization | Real-time 3D data visualization and interaction. | Real-time process data analytics and automated control systems. |

| Industry Impact | Transforms training, design, and remote operations with immersive digital environments. | Revolutionizes manufacturing through intelligent automation and connectivity. |

Which is better?

Industry 4.0 integrates advanced automation, IoT, and AI to optimize manufacturing efficiency and real-time data analytics. The industrial metaverse extends these capabilities by creating immersive, virtual environments for simulation, training, and collaboration, enhancing innovation and remote management. For maximizing productivity and flexibility in modern manufacturing, the industrial metaverse offers a more dynamic and interactive approach compared to traditional Industry 4.0 frameworks.

Connection

Industrial metaverse integrates advanced digital twins, IoT, and AI technologies central to Industry 4.0, enabling immersive simulations and real-time data visualization in manufacturing environments. This convergence enhances predictive maintenance, process optimization, and workforce training through interconnected virtual and physical systems. The synergy drives increased operational efficiency, reduced downtime, and accelerated innovation cycles within smart factories.

Key Terms

Cyber-Physical Systems (CPS)

Industry 4.0 leverages Cyber-Physical Systems (CPS) to integrate physical machinery with digital control systems, enhancing automation and real-time data exchange. The Industrial Metaverse expands on CPS by creating immersive, interconnected virtual environments where digital twins simulate and optimize industrial processes with augmented reality and AI. Explore how the convergence of CPS-driven Industry 4.0 and the Industrial Metaverse is revolutionizing manufacturing efficiency and innovation.

Digital Twin

Industry 4.0 leverages Digital Twin technology to create real-time virtual replicas of physical assets, enhancing predictive maintenance and operational efficiency through IoT and AI integration. The Industrial Metaverse extends this concept by offering immersive, interactive digital environments where Digital Twins collaborate seamlessly across virtual platforms, enabling advanced simulation and remote operations. Explore how these innovations transform manufacturing by bridging the physical and digital worlds.

Immersive Visualization

Immersive visualization in Industry 4.0 leverages augmented reality (AR) and virtual reality (VR) to enhance data interaction on factory floors, improving real-time decision-making and operational efficiency. The industrial metaverse builds on these technologies by creating interconnected virtual environments for remote collaboration, training, and simulation, enabling a more integrated and immersive experience beyond physical constraints. Explore how immersive visualization bridges Industry 4.0 and the industrial metaverse to revolutionize manufacturing workflows.

Source and External Links

Industry 4.0 vs 5.0: What's the Difference? - Rutgers University - Industry 4.0, or the Fourth Industrial Revolution, involves digital industrial technology like cyber-physical systems enabling smart factories with data-driven, versatile manufacturing solutions.

What is Industry 4.0? - IBM - Industry 4.0 is smart manufacturing using IoT, AI, cloud computing, and analytics to create automated, flexible, and efficient production environments with real-time data and predictive maintenance.

What are Industry 4.0, the Fourth Industrial Revolution, and 4IR? - McKinsey - Industry 4.0 represents a transformation driven by connectivity, advanced analytics, and automation, rapidly impacting industries like manufacturing with digital adoption pathways influenced by existing infrastructure and tech readiness.

dowidth.com

dowidth.com