Dark factories utilize fully automated systems that operate without human presence, enhancing efficiency and reducing labor costs in manufacturing. Predictive maintenance employs advanced sensors and AI analytics to anticipate equipment failures, minimizing downtime and extending machinery lifespan. Explore how integrating dark factories with predictive maintenance can transform manufacturing productivity and reliability.

Why it is important

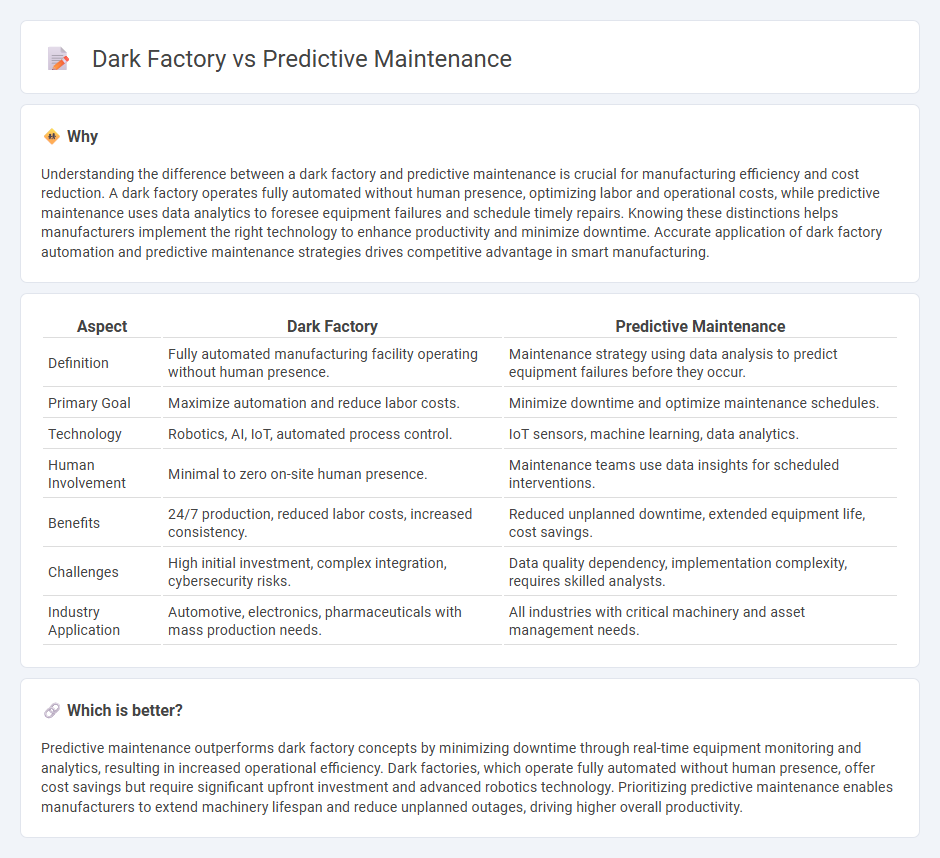

Understanding the difference between a dark factory and predictive maintenance is crucial for manufacturing efficiency and cost reduction. A dark factory operates fully automated without human presence, optimizing labor and operational costs, while predictive maintenance uses data analytics to foresee equipment failures and schedule timely repairs. Knowing these distinctions helps manufacturers implement the right technology to enhance productivity and minimize downtime. Accurate application of dark factory automation and predictive maintenance strategies drives competitive advantage in smart manufacturing.

Comparison Table

| Aspect | Dark Factory | Predictive Maintenance |

|---|---|---|

| Definition | Fully automated manufacturing facility operating without human presence. | Maintenance strategy using data analysis to predict equipment failures before they occur. |

| Primary Goal | Maximize automation and reduce labor costs. | Minimize downtime and optimize maintenance schedules. |

| Technology | Robotics, AI, IoT, automated process control. | IoT sensors, machine learning, data analytics. |

| Human Involvement | Minimal to zero on-site human presence. | Maintenance teams use data insights for scheduled interventions. |

| Benefits | 24/7 production, reduced labor costs, increased consistency. | Reduced unplanned downtime, extended equipment life, cost savings. |

| Challenges | High initial investment, complex integration, cybersecurity risks. | Data quality dependency, implementation complexity, requires skilled analysts. |

| Industry Application | Automotive, electronics, pharmaceuticals with mass production needs. | All industries with critical machinery and asset management needs. |

Which is better?

Predictive maintenance outperforms dark factory concepts by minimizing downtime through real-time equipment monitoring and analytics, resulting in increased operational efficiency. Dark factories, which operate fully automated without human presence, offer cost savings but require significant upfront investment and advanced robotics technology. Prioritizing predictive maintenance enables manufacturers to extend machinery lifespan and reduce unplanned outages, driving higher overall productivity.

Connection

Dark factories leverage advanced automation and IoT sensors to operate with minimal human intervention, generating continuous real-time data streams essential for predictive maintenance algorithms. Predictive maintenance utilizes machine learning models to analyze this sensor data, identifying patterns and anomalies that indicate potential equipment failures before they occur. This integration reduces downtime, optimizes operational efficiency, and extends machinery lifespan within fully automated manufacturing environments.

Key Terms

**Predictive Maintenance:**

Predictive maintenance leverages IoT sensors and machine learning algorithms to analyze real-time equipment data, identifying potential failures before they occur and minimizing unplanned downtime. This approach significantly improves operational efficiency and reduces maintenance costs by enabling timely interventions based on accurate predictions. Explore how predictive maintenance transforms industrial operations and fosters smarter, data-driven decision-making.

Condition Monitoring

Predictive maintenance leverages condition monitoring technologies such as vibration analysis, thermal imaging, and IoT sensors to anticipate equipment failures and optimize maintenance schedules. Dark factories rely heavily on condition monitoring to enable autonomous operations without human intervention, using real-time data to maintain continuous production. Discover how integrating advanced condition monitoring techniques can revolutionize maintenance strategies and factory automation.

Machine Learning Algorithms

Machine learning algorithms play a pivotal role in predictive maintenance by analyzing sensor data to anticipate equipment failures, minimizing downtime and optimizing operational efficiency. In dark factories, these algorithms enable fully automated, unattended production environments by monitoring machines and adapting processes in real-time to maintain continuous operation. Explore how advanced machine learning techniques transform industrial automation by visiting our detailed insights.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses sensor data and machine learning to monitor equipment's real-time condition and predict when maintenance should be performed, reducing downtime and unnecessary costs by addressing issues only as needed.

Predictive maintenance - Wikipedia - Predictive maintenance estimates equipment condition to schedule maintenance more efficiently than time-based methods, preventing unexpected failures and optimizing resources by analyzing current equipment states.

What is Predictive Maintenance? Benefits, Challenges & Examples - Geotab - Predictive maintenance in fleet management leverages real-time data and analytics to forecast vehicle failures, improving uptime, reducing costs, and enhancing safety through timely intervention.

dowidth.com

dowidth.com