Automated guided vehicles (AGVs) are essential in manufacturing for transporting materials along predetermined paths using sensors or markers, enhancing operational accuracy and efficiency. Automated mobile robots (AMRs) offer greater flexibility with advanced navigation systems that allow dynamic route planning and obstacle avoidance, adapting to real-time factory layouts. Discover how these technologies revolutionize production workflows and optimize manufacturing processes.

Why it is important

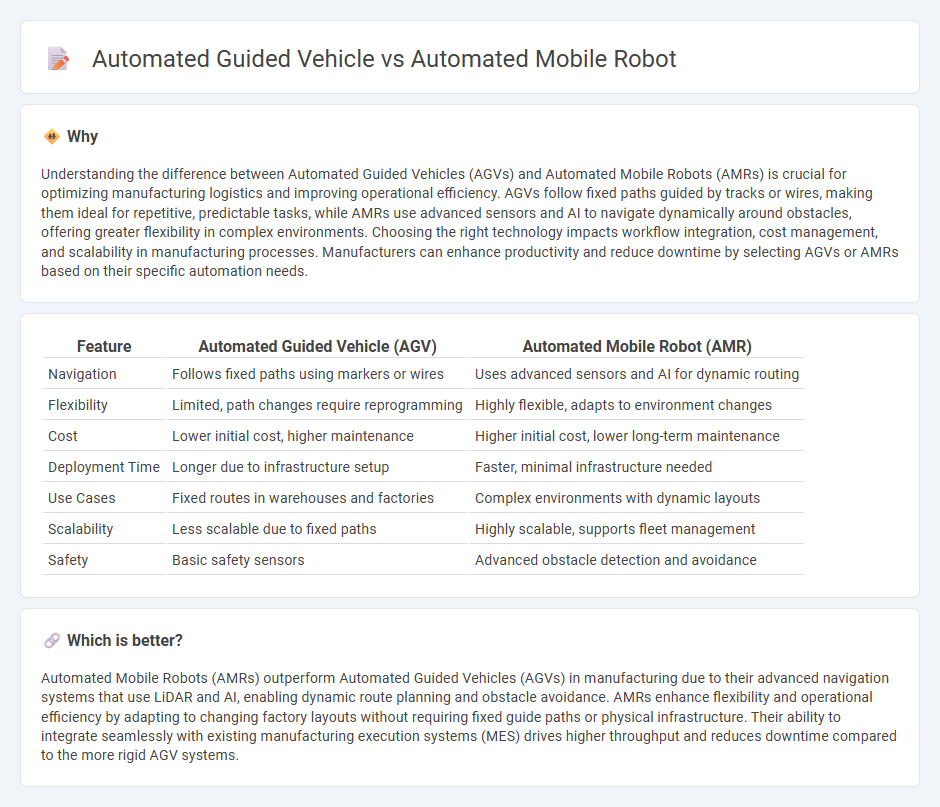

Understanding the difference between Automated Guided Vehicles (AGVs) and Automated Mobile Robots (AMRs) is crucial for optimizing manufacturing logistics and improving operational efficiency. AGVs follow fixed paths guided by tracks or wires, making them ideal for repetitive, predictable tasks, while AMRs use advanced sensors and AI to navigate dynamically around obstacles, offering greater flexibility in complex environments. Choosing the right technology impacts workflow integration, cost management, and scalability in manufacturing processes. Manufacturers can enhance productivity and reduce downtime by selecting AGVs or AMRs based on their specific automation needs.

Comparison Table

| Feature | Automated Guided Vehicle (AGV) | Automated Mobile Robot (AMR) |

|---|---|---|

| Navigation | Follows fixed paths using markers or wires | Uses advanced sensors and AI for dynamic routing |

| Flexibility | Limited, path changes require reprogramming | Highly flexible, adapts to environment changes |

| Cost | Lower initial cost, higher maintenance | Higher initial cost, lower long-term maintenance |

| Deployment Time | Longer due to infrastructure setup | Faster, minimal infrastructure needed |

| Use Cases | Fixed routes in warehouses and factories | Complex environments with dynamic layouts |

| Scalability | Less scalable due to fixed paths | Highly scalable, supports fleet management |

| Safety | Basic safety sensors | Advanced obstacle detection and avoidance |

Which is better?

Automated Mobile Robots (AMRs) outperform Automated Guided Vehicles (AGVs) in manufacturing due to their advanced navigation systems that use LiDAR and AI, enabling dynamic route planning and obstacle avoidance. AMRs enhance flexibility and operational efficiency by adapting to changing factory layouts without requiring fixed guide paths or physical infrastructure. Their ability to integrate seamlessly with existing manufacturing execution systems (MES) drives higher throughput and reduces downtime compared to the more rigid AGV systems.

Connection

Automated Guided Vehicles (AGVs) and Automated Mobile Robots (AMRs) are connected through their roles in streamlining manufacturing material handling by autonomously transporting goods within production facilities. Both technologies utilize sensors, navigation systems, and real-time data processing to optimize workflow efficiency and reduce human labor costs. Integration of AGVs and AMRs enhances factory automation by enabling flexible routing, precise delivery, and improved logistics management in smart manufacturing environments.

Key Terms

Navigation System

Automated mobile robots (AMRs) use advanced navigation systems such as LiDAR, computer vision, and real-time mapping to autonomously maneuver complex environments with high flexibility. Automated guided vehicles (AGVs) rely on predetermined paths using magnetic strips, wires, or markers for navigation, offering reliable but limited route adaptability. Explore the key differences in navigation technologies to determine the best fit for your logistics or manufacturing needs.

Flexibility

Automated mobile robots (AMRs) provide superior flexibility compared to automated guided vehicles (AGVs) due to their ability to navigate dynamic environments using advanced sensors and AI-driven path planning. Unlike AGVs that rely on fixed routes or tracks, AMRs can adapt to changing warehouse layouts and obstacles in real time, enhancing operational efficiency. Explore further to understand how flexibility impacts automation choices in logistics and manufacturing.

Infrastructure Requirements

Automated mobile robots (AMRs) require minimal infrastructure modifications as they use onboard sensors, cameras, and advanced algorithms to navigate dynamically within environments without fixed guides. Automated guided vehicles (AGVs) depend heavily on physical infrastructure such as magnetic strips, wiring, or embedded markers for navigation, leading to higher upfront installation costs and limited route flexibility. Explore further to understand how infrastructure demands impact operational efficiency and scalability for AMRs and AGVs.

Source and External Links

Autonomous Mobile Robots (AMRs): A Guide | Built In - Autonomous mobile robots (AMRs) are robots capable of navigating their environment independently using sensors and preprogrammed maps, offering greater flexibility than automated guided vehicles (AGVs), and are widely used in warehouses, manufacturing, and delivery applications.

Automated & Autonomous Mobile Robots | Robotnik(r) - Robotnik's AMRs perform tasks autonomously in dynamic environments using advanced SLAM technology, adapting flexibly across industries like logistics, manufacturing, inspection, and retail while collaborating with human workers.

Autonomous Mobile Robots (AMRs) - ABB AMR/AGV robots - ABB's AMRs are advanced transport robots designed for autonomous load movement in diverse industries, featuring robust safety systems, AI-powered navigation, and versatility in applications from material handling to logistic center automation.

dowidth.com

dowidth.com