Microfactories emphasize localized, small-scale production using modular, flexible equipment to enable rapid customization and reduced lead times. Lights-out manufacturing relies on fully automated systems operating without human intervention, maximizing efficiency and minimizing labor costs through robotic automation and continuous operation. Explore detailed comparisons to understand which approach best suits modern manufacturing demands.

Why it is important

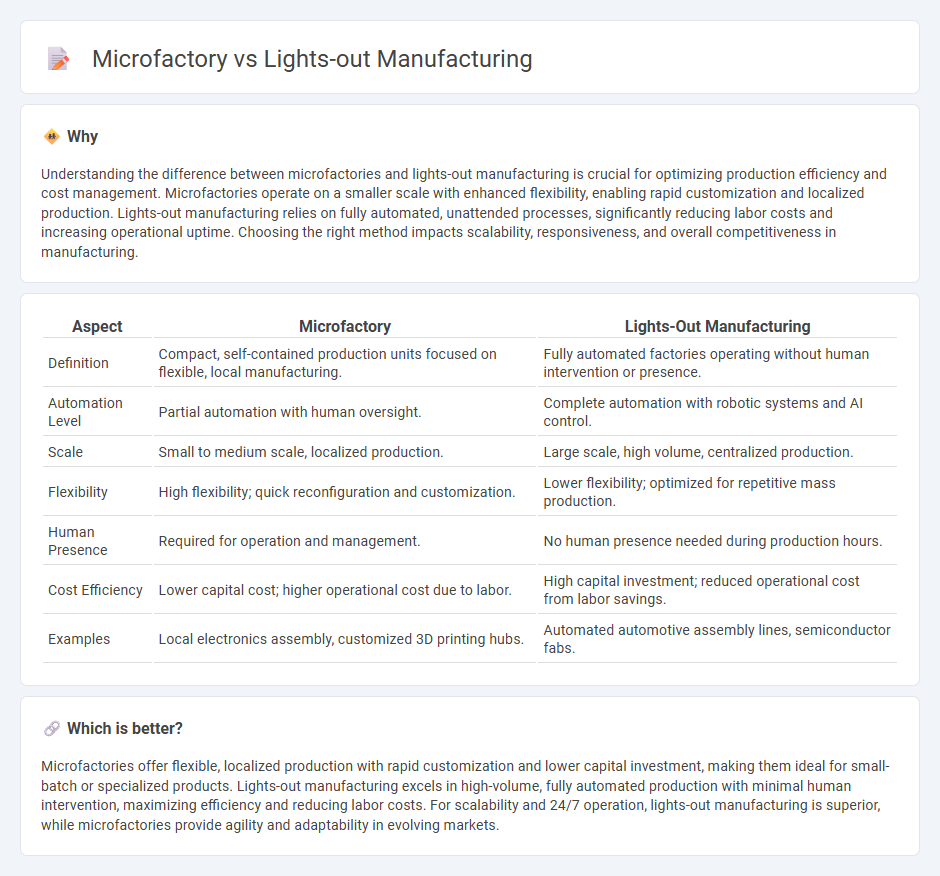

Understanding the difference between microfactories and lights-out manufacturing is crucial for optimizing production efficiency and cost management. Microfactories operate on a smaller scale with enhanced flexibility, enabling rapid customization and localized production. Lights-out manufacturing relies on fully automated, unattended processes, significantly reducing labor costs and increasing operational uptime. Choosing the right method impacts scalability, responsiveness, and overall competitiveness in manufacturing.

Comparison Table

| Aspect | Microfactory | Lights-Out Manufacturing |

|---|---|---|

| Definition | Compact, self-contained production units focused on flexible, local manufacturing. | Fully automated factories operating without human intervention or presence. |

| Automation Level | Partial automation with human oversight. | Complete automation with robotic systems and AI control. |

| Scale | Small to medium scale, localized production. | Large scale, high volume, centralized production. |

| Flexibility | High flexibility; quick reconfiguration and customization. | Lower flexibility; optimized for repetitive mass production. |

| Human Presence | Required for operation and management. | No human presence needed during production hours. |

| Cost Efficiency | Lower capital cost; higher operational cost due to labor. | High capital investment; reduced operational cost from labor savings. |

| Examples | Local electronics assembly, customized 3D printing hubs. | Automated automotive assembly lines, semiconductor fabs. |

Which is better?

Microfactories offer flexible, localized production with rapid customization and lower capital investment, making them ideal for small-batch or specialized products. Lights-out manufacturing excels in high-volume, fully automated production with minimal human intervention, maximizing efficiency and reducing labor costs. For scalability and 24/7 operation, lights-out manufacturing is superior, while microfactories provide agility and adaptability in evolving markets.

Connection

Microfactories leverage compact, modular setups that integrate lights-out manufacturing to achieve fully automated, unmanned production environments. Lights-out manufacturing uses robotics and AI to operate continuously without human intervention, enabling microfactories to produce customized goods efficiently at lower costs. This combination enhances scalability, reduces overhead, and accelerates time-to-market in advanced manufacturing ecosystems.

Key Terms

**Lights-out manufacturing:**

Lights-out manufacturing refers to fully automated production processes operating without human intervention, often utilizing robotics, AI, and IoT technologies to maximize efficiency and minimize labor costs. This approach excels in high-volume, repetitive tasks, enabling continuous operation and reduced error rates in industries like electronics, automotive, and semiconductors. Discover how lights-out manufacturing transforms production workflows and drives industrial innovation.

Automation

Lights-out manufacturing leverages fully autonomous systems operating without human intervention, maximizing efficiency and minimizing errors through advanced robotics and AI-driven processes; it excels in large-scale production environments. Microfactories emphasize flexible, scalable automation suitable for localized, small-batch manufacturing, integrating smart technologies to streamline workflows and reduce operational footprints. Explore the distinct automation benefits and applications of each to optimize your manufacturing strategy.

Unmanned operation

Lights-out manufacturing relies on fully automated production processes with minimal human intervention, enabling 24/7 operations that increase efficiency and reduce labor costs. Microfactories integrate compact, scalable units designed for flexible manufacturing, often incorporating unmanned operation through robotics and IoT technology to optimize production in smaller spaces. Explore how these advanced unmanned systems redefine manufacturing agility and operational resilience.

Source and External Links

Lights-out factory - Siemens Digital Industries Software - Lights-out manufacturing, or dark factory, refers to highly automated production with minimal or zero human intervention, often run in darkness, using robots and manufacturing operations management software for remote monitoring and control.

What is Lights Out Manufacturing? Exploring Full Automation - Lights-out manufacturing is a production method utilizing fully automated technology to run factories with little or no human presence, reducing costs and increasing consistency by allowing machines to operate independently 24/7.

What is "Lights Out" Dark Manufacturing? | ATS - Dark or lights-out manufacturing plants are automated facilities that operate without or with minimal human intervention, enabled by robotics, AI, and IoT technologies, aiming to optimize efficiency and reduce labor costs.

dowidth.com

dowidth.com