Mass customization combines the efficiency of mass production with personalized product variations, enabling businesses to meet diverse customer demands rapidly. Job shop production focuses on small-batch, highly customized manufacturing processes tailored to unique orders, prioritizing flexibility and specialized craftsmanship. Explore these manufacturing strategies to optimize your production approach for specific market needs.

Why it is important

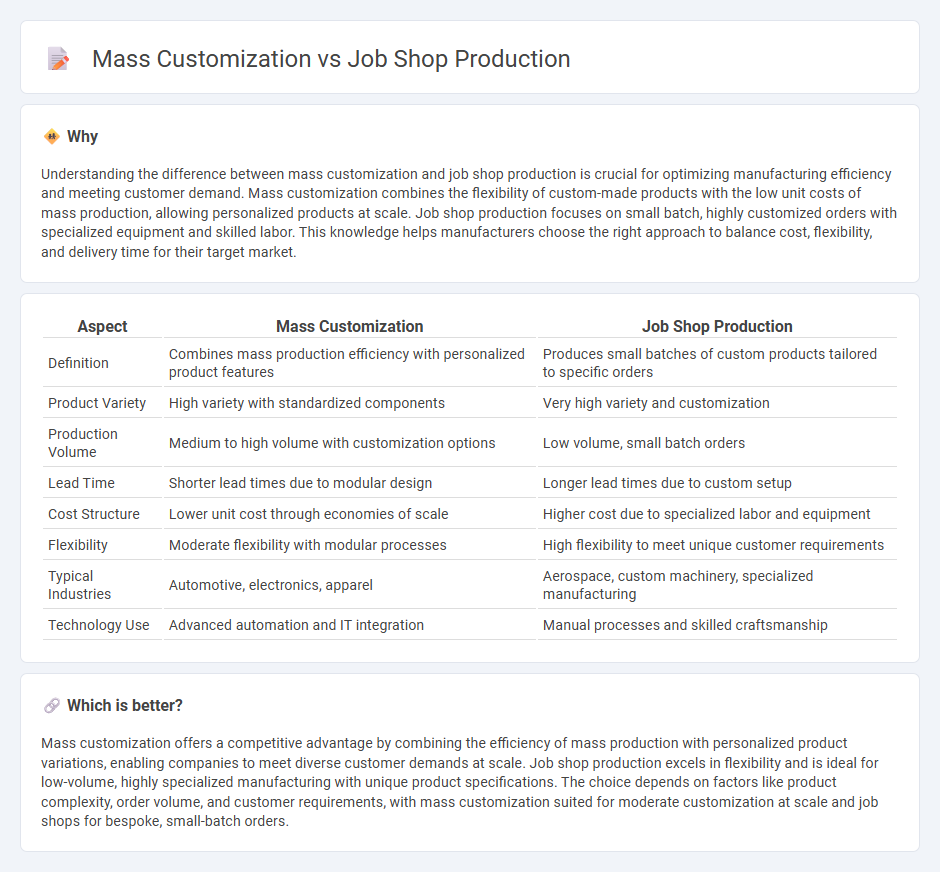

Understanding the difference between mass customization and job shop production is crucial for optimizing manufacturing efficiency and meeting customer demand. Mass customization combines the flexibility of custom-made products with the low unit costs of mass production, allowing personalized products at scale. Job shop production focuses on small batch, highly customized orders with specialized equipment and skilled labor. This knowledge helps manufacturers choose the right approach to balance cost, flexibility, and delivery time for their target market.

Comparison Table

| Aspect | Mass Customization | Job Shop Production |

|---|---|---|

| Definition | Combines mass production efficiency with personalized product features | Produces small batches of custom products tailored to specific orders |

| Product Variety | High variety with standardized components | Very high variety and customization |

| Production Volume | Medium to high volume with customization options | Low volume, small batch orders |

| Lead Time | Shorter lead times due to modular design | Longer lead times due to custom setup |

| Cost Structure | Lower unit cost through economies of scale | Higher cost due to specialized labor and equipment |

| Flexibility | Moderate flexibility with modular processes | High flexibility to meet unique customer requirements |

| Typical Industries | Automotive, electronics, apparel | Aerospace, custom machinery, specialized manufacturing |

| Technology Use | Advanced automation and IT integration | Manual processes and skilled craftsmanship |

Which is better?

Mass customization offers a competitive advantage by combining the efficiency of mass production with personalized product variations, enabling companies to meet diverse customer demands at scale. Job shop production excels in flexibility and is ideal for low-volume, highly specialized manufacturing with unique product specifications. The choice depends on factors like product complexity, order volume, and customer requirements, with mass customization suited for moderate customization at scale and job shops for bespoke, small-batch orders.

Connection

Mass customization leverages job shop production principles by utilizing flexible, small-batch processes to create tailored products that meet individual customer specifications. Job shop production's ability to handle diverse tasks and variable workflows enables manufacturers to efficiently produce customized goods without sacrificing quality or speed. This integration supports market demand for personalized products through adaptable manufacturing systems and skilled labor.

Key Terms

Process Flexibility

Job shop production excels in process flexibility by handling small, customized batches with varied workflows, enabling rapid adjustments to product specifications and resource allocation. Mass customization integrates flexible manufacturing systems and modular product designs to deliver personalized products at scale without compromising efficiency. Explore how advanced process flexibility strategies can optimize your production approach for diverse market demands.

Product Variety

Job shop production offers high product variety by producing small batches tailored to specific customer requirements, ideal for custom and diverse product demands. Mass customization combines mass production efficiency with customization, enabling a wide range of options while maintaining lower costs and faster turnaround times. Explore deeper insights on how these production methods impact product variety and operational strategies.

Production Volume

Job shop production typically handles low to moderate volumes with high variability, producing customized products tailored to specific client requirements. Mass customization, however, combines the efficiency of mass production with the flexibility to offer personalized products at higher volumes, leveraging modular designs and advanced manufacturing technologies. Explore the key differences and benefits of each approach to optimize your production strategy.

Source and External Links

Job Shop Manufacturing: Everything You Need to Know - Job shop production is a manufacturing process where workstations are specialized by function, allowing manufacturers to produce customized, small batches of products such as customizable wooden eyeglasses with steps including design, material preparation, cutting, and assembly.

Job Shop Manufacturing: The Detailed Guide - Deskera - Job shop manufacturing handles made-to-order small batches where production involves customization of design, preparation of materials, cutting, welding or rolling, inspection, tooling, and metal spinning or shaping per customer specifications.

Job Shop vs. Production Manufacturing: Key Differences - Job shops focus on make-to-order custom parts with complex, unique workflows and minimal inventory, requiring frequent machine setup, unlike production manufacturing which is large-scale, made-to-stock, and less flexible.

dowidth.com

dowidth.com