Generative design uses advanced algorithms and artificial intelligence to create optimized manufacturing models tailored to specific performance criteria, enabling innovative and efficient product development. Template-based design relies on predefined patterns and established frameworks, offering quicker turnaround but limited customization and flexibility. Explore the key differences and benefits to determine the best approach for your manufacturing needs.

Why it is important

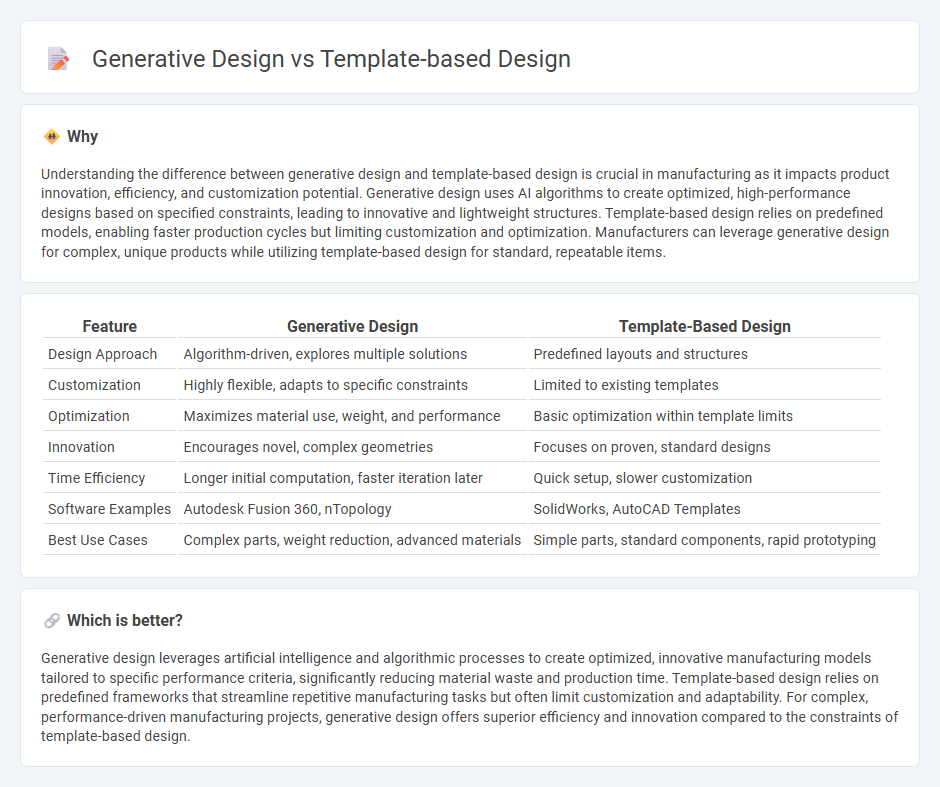

Understanding the difference between generative design and template-based design is crucial in manufacturing as it impacts product innovation, efficiency, and customization potential. Generative design uses AI algorithms to create optimized, high-performance designs based on specified constraints, leading to innovative and lightweight structures. Template-based design relies on predefined models, enabling faster production cycles but limiting customization and optimization. Manufacturers can leverage generative design for complex, unique products while utilizing template-based design for standard, repeatable items.

Comparison Table

| Feature | Generative Design | Template-Based Design |

|---|---|---|

| Design Approach | Algorithm-driven, explores multiple solutions | Predefined layouts and structures |

| Customization | Highly flexible, adapts to specific constraints | Limited to existing templates |

| Optimization | Maximizes material use, weight, and performance | Basic optimization within template limits |

| Innovation | Encourages novel, complex geometries | Focuses on proven, standard designs |

| Time Efficiency | Longer initial computation, faster iteration later | Quick setup, slower customization |

| Software Examples | Autodesk Fusion 360, nTopology | SolidWorks, AutoCAD Templates |

| Best Use Cases | Complex parts, weight reduction, advanced materials | Simple parts, standard components, rapid prototyping |

Which is better?

Generative design leverages artificial intelligence and algorithmic processes to create optimized, innovative manufacturing models tailored to specific performance criteria, significantly reducing material waste and production time. Template-based design relies on predefined frameworks that streamline repetitive manufacturing tasks but often limit customization and adaptability. For complex, performance-driven manufacturing projects, generative design offers superior efficiency and innovation compared to the constraints of template-based design.

Connection

Generative design uses algorithms to create multiple optimized manufacturing models based on specific constraints, while template-based design provides predefined structures to streamline the development process. Integrating generative design with template-based design enhances efficiency by allowing automated customization within established frameworks, reducing time and resource consumption. This synergy drives innovation in manufacturing by combining computational creativity with practical standardization.

Key Terms

Parametric Modeling

Template-based design uses predefined parameters and fixed templates, enabling rapid iteration within well-defined constraints but limiting creative flexibility. Generative design leverages algorithms and computational power to explore numerous design permutations, optimizing for performance and innovation through parametric modeling. Discover how parametric modeling transforms design workflows by balancing control and creativity.

Algorithmic Optimization

Template-based design relies on predefined structures and parametric constraints to streamline the design process, often limiting variability but ensuring consistency. Generative design utilizes algorithmic optimization and artificial intelligence to explore vast design possibilities, optimizing for criteria such as weight, strength, and material use. Discover how algorithmic optimization transforms design workflows by unlocking innovative and efficient solutions beyond traditional templates.

Topology Optimization

Topology optimization in template-based design relies on predefined shapes and organizational rules to achieve material efficiency and structural performance, making it suitable for straightforward engineering tasks. Generative design uses algorithms to explore vast design spaces, optimizing structures by simulating multiple load conditions, resulting in innovative and often non-intuitive topologies. Discover how integrating both approaches can revolutionize product development and enhance structural resilience.

Source and External Links

FAQ: Why Is Template-Based Design the Most Practical Choice? - Template-based design offers a cost-effective, time-saving, and highly customizable approach to building websites, allowing layout, visual, and functional modifications to suit specific needs while being flexible and efficient.

Template method pattern - Wikipedia - The template method is a behavioral design pattern in object-oriented programming where a superclass defines the skeleton of an operation with abstract or hook methods, allowing subclasses to customize parts of the algorithm without changing its structure.

Template Method - Refactoring.Guru - This pattern lets you break a complex algorithm into steps defined in a superclass, with subclasses overriding specific steps to extend behavior while keeping the overall algorithm intact and reducing code duplication.

dowidth.com

dowidth.com