Remanufacturing involves restoring used products to like-new condition through disassembly, cleaning, repairing, and reassembly, significantly extending the product's life cycle and reducing waste. Recycling breaks down materials from discarded products to create raw materials, often leading to quality degradation and higher energy consumption compared to remanufacturing. Discover how these sustainable processes impact manufacturing efficiency and environmental goals.

Why it is important

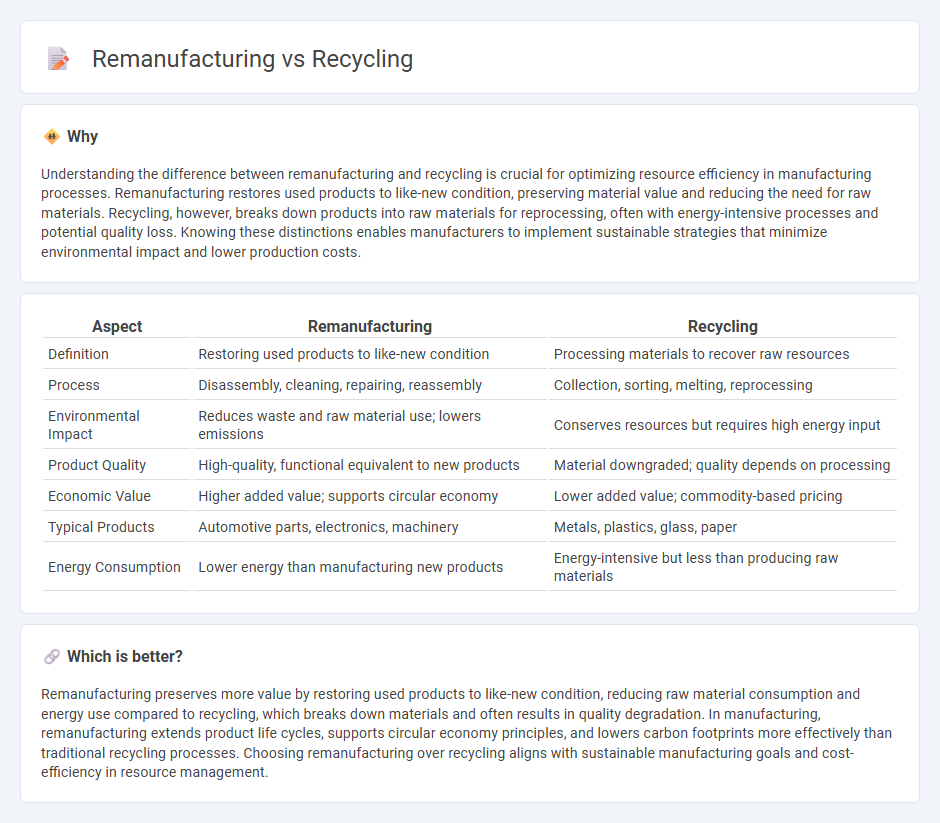

Understanding the difference between remanufacturing and recycling is crucial for optimizing resource efficiency in manufacturing processes. Remanufacturing restores used products to like-new condition, preserving material value and reducing the need for raw materials. Recycling, however, breaks down products into raw materials for reprocessing, often with energy-intensive processes and potential quality loss. Knowing these distinctions enables manufacturers to implement sustainable strategies that minimize environmental impact and lower production costs.

Comparison Table

| Aspect | Remanufacturing | Recycling |

|---|---|---|

| Definition | Restoring used products to like-new condition | Processing materials to recover raw resources |

| Process | Disassembly, cleaning, repairing, reassembly | Collection, sorting, melting, reprocessing |

| Environmental Impact | Reduces waste and raw material use; lowers emissions | Conserves resources but requires high energy input |

| Product Quality | High-quality, functional equivalent to new products | Material downgraded; quality depends on processing |

| Economic Value | Higher added value; supports circular economy | Lower added value; commodity-based pricing |

| Typical Products | Automotive parts, electronics, machinery | Metals, plastics, glass, paper |

| Energy Consumption | Lower energy than manufacturing new products | Energy-intensive but less than producing raw materials |

Which is better?

Remanufacturing preserves more value by restoring used products to like-new condition, reducing raw material consumption and energy use compared to recycling, which breaks down materials and often results in quality degradation. In manufacturing, remanufacturing extends product life cycles, supports circular economy principles, and lowers carbon footprints more effectively than traditional recycling processes. Choosing remanufacturing over recycling aligns with sustainable manufacturing goals and cost-efficiency in resource management.

Connection

Remanufacturing and recycling are interconnected processes within sustainable manufacturing that minimize waste and conserve resources by extending the lifecycle of products. Remanufacturing involves refurbishing used components to meet original specifications, while recycling processes recover raw materials from end-of-life products for reuse in manufacturing. Both methods contribute to reducing environmental impact and lowering production costs through efficient material usage and resource recovery.

Key Terms

Material Recovery

Recycling involves breaking down materials to recover raw resources, often leading to quality degradation and energy-intensive processing. Remanufacturing restores used products to like-new condition, preserving material integrity and reducing waste significantly. Explore the benefits of remanufacturing for sustainable material recovery and resource efficiency.

Product Life Extension

Recycling involves breaking down used products to recover raw materials, whereas remanufacturing restores products to like-new condition, significantly extending their lifespan and reducing resource consumption. Remanufacturing enhances product life extension by maintaining original quality and performance standards, leading to lower environmental impact compared to recycling. Explore the benefits and processes of remanufacturing to understand its role in sustainable product life cycle management.

Resource Efficiency

Recycling involves processing materials to recover raw resources, often leading to downcycling and quality loss, while remanufacturing restores used products to like-new condition, preserving material value and reducing energy consumption by up to 85%. Remanufacturing supports circular economy goals by extending product life cycles and minimizing waste generation compared to traditional recycling practices. Explore detailed insights on how remanufacturing enhances resource efficiency and contributes to sustainable manufacturing.

Source and External Links

Recycling - Wikipedia - Recycling is the process of converting waste materials into new materials and objects, involving stages of collection, sorting (often automated), and processing to create recyclates for new products.

Recycling Basics and Benefits | US EPA - Recycling involves collecting and processing waste materials to manufacture new products, providing environmental, economic, and community benefits, following a three-step continuous loop of collection, processing, and manufacturing.

Bi-Weekly Curbside Recycling Collection - A detailed guide on curbside recycling specifies recyclable items including paper, metals, glass, and plastics, while noting exclusions such as Styrofoam and flimsy plastics that can jam machinery and must be reused or disposed of as trash.

dowidth.com

dowidth.com