Factory as a Service (FaaS) leverages on-demand access to fully equipped production facilities, enabling businesses to scale manufacturing without capital-intensive investments. Manufacturing-as-a-Service (MaaS) integrates advanced digital platforms with end-to-end production processes, offering customized manufacturing solutions and enhanced operational flexibility. Explore the key differences and advantages of FaaS and MaaS to optimize your manufacturing strategy.

Why it is important

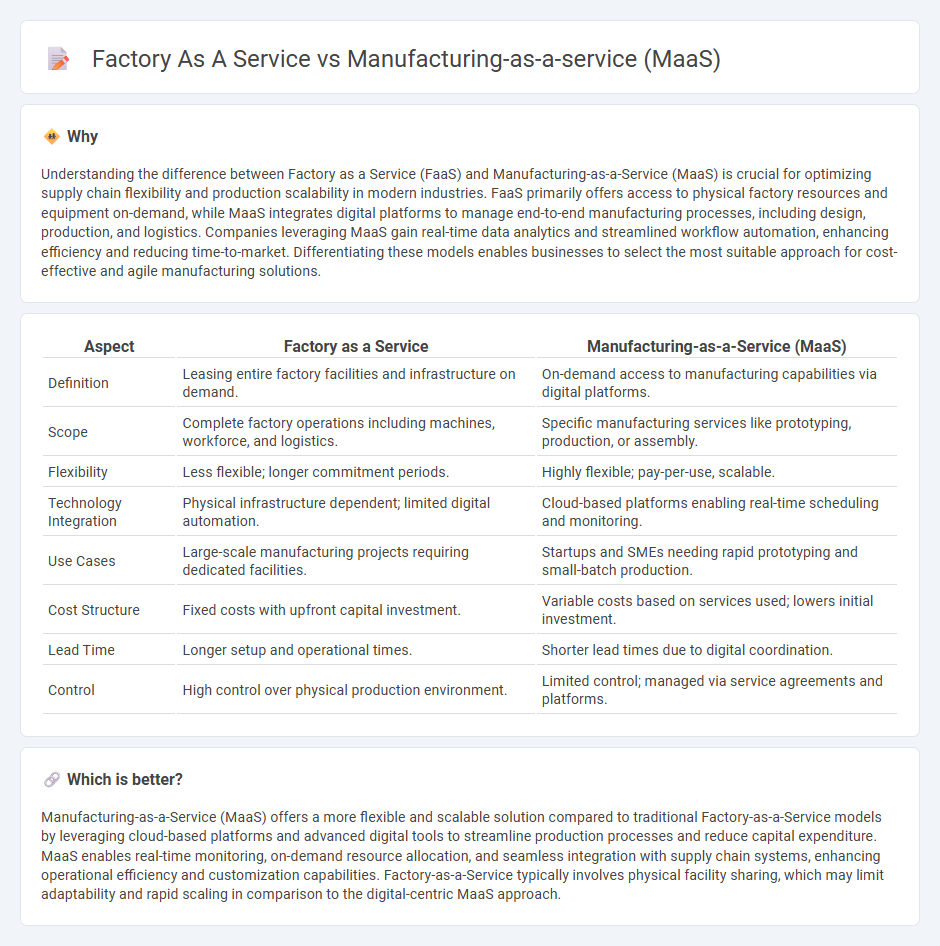

Understanding the difference between Factory as a Service (FaaS) and Manufacturing-as-a-Service (MaaS) is crucial for optimizing supply chain flexibility and production scalability in modern industries. FaaS primarily offers access to physical factory resources and equipment on-demand, while MaaS integrates digital platforms to manage end-to-end manufacturing processes, including design, production, and logistics. Companies leveraging MaaS gain real-time data analytics and streamlined workflow automation, enhancing efficiency and reducing time-to-market. Differentiating these models enables businesses to select the most suitable approach for cost-effective and agile manufacturing solutions.

Comparison Table

| Aspect | Factory as a Service | Manufacturing-as-a-Service (MaaS) |

|---|---|---|

| Definition | Leasing entire factory facilities and infrastructure on demand. | On-demand access to manufacturing capabilities via digital platforms. |

| Scope | Complete factory operations including machines, workforce, and logistics. | Specific manufacturing services like prototyping, production, or assembly. |

| Flexibility | Less flexible; longer commitment periods. | Highly flexible; pay-per-use, scalable. |

| Technology Integration | Physical infrastructure dependent; limited digital automation. | Cloud-based platforms enabling real-time scheduling and monitoring. |

| Use Cases | Large-scale manufacturing projects requiring dedicated facilities. | Startups and SMEs needing rapid prototyping and small-batch production. |

| Cost Structure | Fixed costs with upfront capital investment. | Variable costs based on services used; lowers initial investment. |

| Lead Time | Longer setup and operational times. | Shorter lead times due to digital coordination. |

| Control | High control over physical production environment. | Limited control; managed via service agreements and platforms. |

Which is better?

Manufacturing-as-a-Service (MaaS) offers a more flexible and scalable solution compared to traditional Factory-as-a-Service models by leveraging cloud-based platforms and advanced digital tools to streamline production processes and reduce capital expenditure. MaaS enables real-time monitoring, on-demand resource allocation, and seamless integration with supply chain systems, enhancing operational efficiency and customization capabilities. Factory-as-a-Service typically involves physical facility sharing, which may limit adaptability and rapid scaling in comparison to the digital-centric MaaS approach.

Connection

Factory as a Service (FaaS) and Manufacturing-as-a-Service (MaaS) are interconnected cloud-based production models that enable businesses to outsource manufacturing processes through digital platforms. Both leverage IoT, AI, and data analytics to optimize production efficiency, reduce capital expenditure, and provide scalable access to factory capabilities without owning physical assets. These models facilitate on-demand manufacturing, supply chain agility, and seamless integration between virtual orders and real-world factory operations.

Key Terms

Cloud-based Production

Manufacturing-as-a-Service (MaaS) leverages cloud-based platforms to offer on-demand access to distributed manufacturing resources, enabling flexible production scaling and real-time supply chain integration. Factory as a Service (FaaS) emphasizes virtualized factory environments managed via the cloud, providing end-to-end operational control and seamless automation across multiple production sites. Explore how cloud-based technologies are transforming industrial manufacturing by integrating MaaS and FaaS solutions for optimized production workflows.

On-demand Manufacturing

Manufacturing-as-a-Service (MaaS) offers scalable, cloud-based access to manufacturing resources enabling businesses to produce customized products on demand without owning physical assets. Factory-as-a-Service (FaaS) integrates entire factory operations into a flexible, remotely managed service, emphasizing real-time control and end-to-end production efficiency for on-demand manufacturing. Explore how MaaS and FaaS reshape agile, cost-effective production models to meet market demands rapidly.

Digital Supply Chain

Manufacturing-as-a-Service (MaaS) leverages cloud-based platforms to provide on-demand access to distributed manufacturing resources, optimizing production flexibility and scalability within the digital supply chain. Factory-as-a-Service (FaaS) emphasizes smart factory facilities equipped with IoT, AI, and real-time data analytics to streamline processes and enhance supply chain visibility. Explore how these models revolutionize digital supply chain strategies for enhanced efficiency and responsiveness.

Source and External Links

Manufacturing As A Service Explained And Why It Is The Future - MaaS is a digital-driven production model where businesses submit manufacturing requests to a cloud-based platform, leveraging AI and real-time analytics to connect with a global network of manufacturers for streamlined, cost-effective production.

What is Manufacturing-as-a-Service (MaaS)? - MaaS extends the "as-a-service" model to manufacturing, offering on-demand access to manufacturing resources and expertise via subscription or pay-per-use, eliminating the need for companies to own or operate their own facilities.

What is Manufacturing as a Service (MaaS)? - MaaS enables companies to utilize external manufacturing capabilities on-demand, reducing capital investment and entry barriers by tapping into a global network of service providers for scalable, flexible production solutions.

dowidth.com

dowidth.com