Process mining leverages data analytics to visualize and optimize manufacturing workflows by extracting insights from event logs, enhancing operational transparency and efficiency. Industrial engineering focuses on designing, improving, and implementing integrated systems involving humans, materials, and machines to increase productivity and reduce waste. Explore further to understand how these disciplines complement each other in advancing manufacturing excellence.

Why it is important

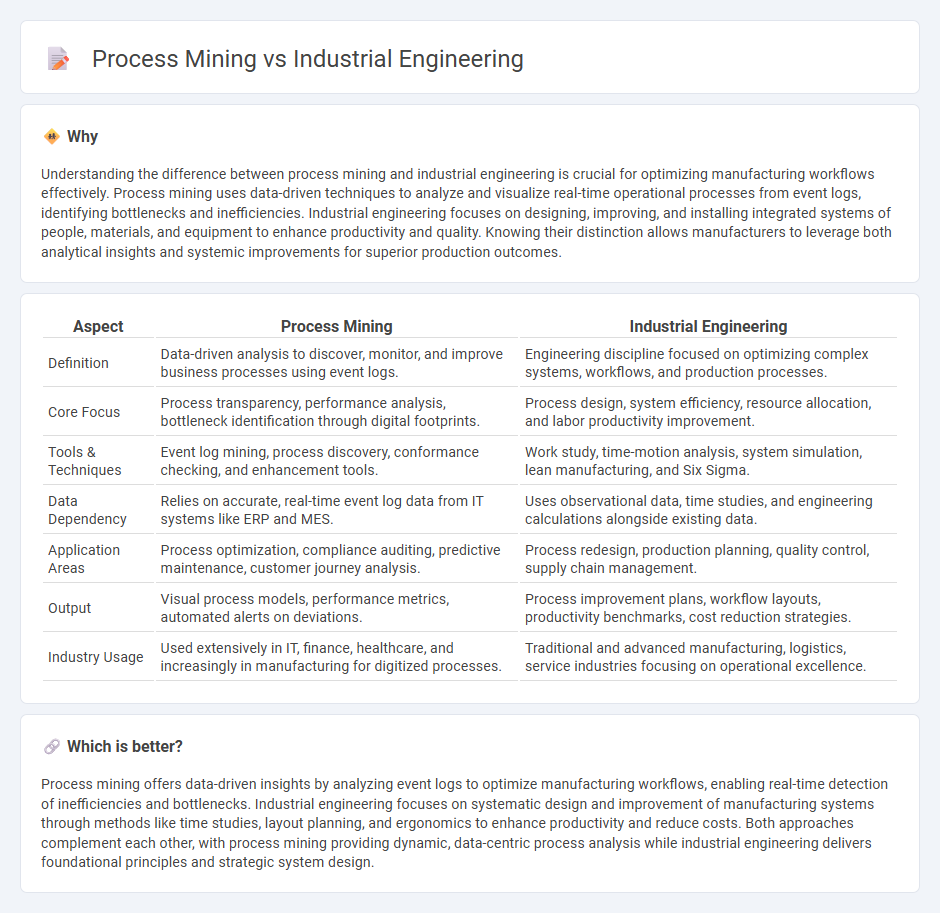

Understanding the difference between process mining and industrial engineering is crucial for optimizing manufacturing workflows effectively. Process mining uses data-driven techniques to analyze and visualize real-time operational processes from event logs, identifying bottlenecks and inefficiencies. Industrial engineering focuses on designing, improving, and installing integrated systems of people, materials, and equipment to enhance productivity and quality. Knowing their distinction allows manufacturers to leverage both analytical insights and systemic improvements for superior production outcomes.

Comparison Table

| Aspect | Process Mining | Industrial Engineering |

|---|---|---|

| Definition | Data-driven analysis to discover, monitor, and improve business processes using event logs. | Engineering discipline focused on optimizing complex systems, workflows, and production processes. |

| Core Focus | Process transparency, performance analysis, bottleneck identification through digital footprints. | Process design, system efficiency, resource allocation, and labor productivity improvement. |

| Tools & Techniques | Event log mining, process discovery, conformance checking, and enhancement tools. | Work study, time-motion analysis, system simulation, lean manufacturing, and Six Sigma. |

| Data Dependency | Relies on accurate, real-time event log data from IT systems like ERP and MES. | Uses observational data, time studies, and engineering calculations alongside existing data. |

| Application Areas | Process optimization, compliance auditing, predictive maintenance, customer journey analysis. | Process redesign, production planning, quality control, supply chain management. |

| Output | Visual process models, performance metrics, automated alerts on deviations. | Process improvement plans, workflow layouts, productivity benchmarks, cost reduction strategies. |

| Industry Usage | Used extensively in IT, finance, healthcare, and increasingly in manufacturing for digitized processes. | Traditional and advanced manufacturing, logistics, service industries focusing on operational excellence. |

Which is better?

Process mining offers data-driven insights by analyzing event logs to optimize manufacturing workflows, enabling real-time detection of inefficiencies and bottlenecks. Industrial engineering focuses on systematic design and improvement of manufacturing systems through methods like time studies, layout planning, and ergonomics to enhance productivity and reduce costs. Both approaches complement each other, with process mining providing dynamic, data-centric process analysis while industrial engineering delivers foundational principles and strategic system design.

Connection

Process mining leverages data from industrial systems to analyze and optimize manufacturing workflows, providing actionable insights into production efficiency. Industrial engineering applies these insights to design, improve, and implement efficient manufacturing processes, reducing waste and enhancing productivity. Together, they drive continuous improvement by combining data-driven process analysis with systematic engineering principles.

Key Terms

**Industrial Engineering:**

Industrial Engineering optimizes complex systems and processes by integrating human factors, operations research, and systems design to improve efficiency and productivity. It employs techniques like time-motion studies, simulation, and quality control to streamline manufacturing and service operations. Explore how Industrial Engineering principles drive innovation and operational excellence.

Lean Manufacturing

Industrial engineering emphasizes optimizing production systems through methods like Lean Manufacturing to enhance efficiency, reduce waste, and improve quality. Process mining leverages data analytics and event logs to uncover bottlenecks, deviations, and inefficiencies within manufacturing processes, providing actionable insights for continuous improvement. Explore the intersection of industrial engineering and process mining to unlock advanced strategies for Lean Manufacturing optimization.

Work Standardization

Industrial engineering prioritizes work standardization by designing efficient workflows, reducing variability, and optimizing resource allocation to enhance productivity and quality. Process mining leverages data-driven analysis to discover, monitor, and improve actual work processes by extracting knowledge from event logs, identifying deviations from standardized procedures, and enabling continuous improvement. Explore how integrating industrial engineering principles with process mining techniques can revolutionize work standardization in your organization.

Source and External Links

Industrial Engineering - Industrial engineering involves designing, improving, and installing integrated systems to optimize efficiency, productivity, and quality across various sectors.

Industrial Engineering (IE) - Ingram School of Engineering - Industrial engineers optimize systems to improve productivity and workers' environments by applying innovative solutions and methodologies.

What Do Industrial Engineers Do? - Industrial engineers use technical skills to analyze and improve organizational processes, leveraging software and technologies.

dowidth.com

dowidth.com