Human augmentation in manufacturing enhances worker capabilities through wearable devices and exoskeletons, improving precision and reducing fatigue. Cyber-physical systems integrate computational algorithms with physical production processes to enable real-time monitoring and autonomous decision-making on factory floors. Discover how these technologies revolutionize industrial efficiency and safety.

Why it is important

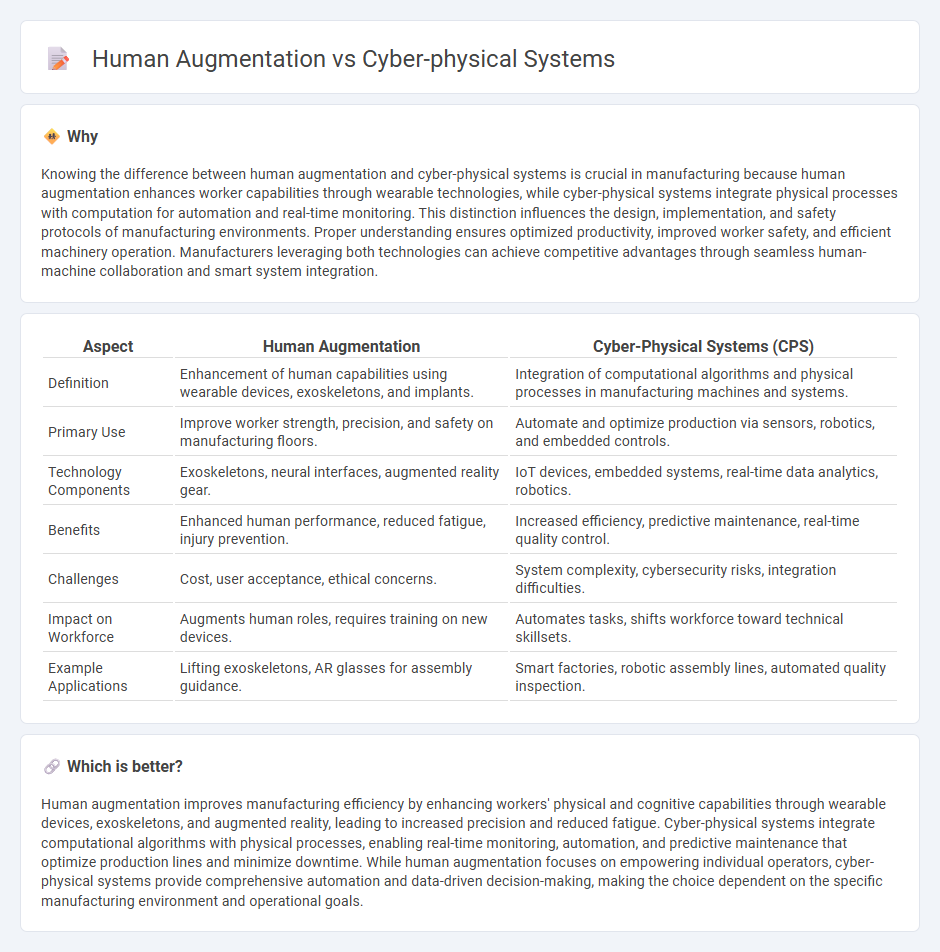

Knowing the difference between human augmentation and cyber-physical systems is crucial in manufacturing because human augmentation enhances worker capabilities through wearable technologies, while cyber-physical systems integrate physical processes with computation for automation and real-time monitoring. This distinction influences the design, implementation, and safety protocols of manufacturing environments. Proper understanding ensures optimized productivity, improved worker safety, and efficient machinery operation. Manufacturers leveraging both technologies can achieve competitive advantages through seamless human-machine collaboration and smart system integration.

Comparison Table

| Aspect | Human Augmentation | Cyber-Physical Systems (CPS) |

|---|---|---|

| Definition | Enhancement of human capabilities using wearable devices, exoskeletons, and implants. | Integration of computational algorithms and physical processes in manufacturing machines and systems. |

| Primary Use | Improve worker strength, precision, and safety on manufacturing floors. | Automate and optimize production via sensors, robotics, and embedded controls. |

| Technology Components | Exoskeletons, neural interfaces, augmented reality gear. | IoT devices, embedded systems, real-time data analytics, robotics. |

| Benefits | Enhanced human performance, reduced fatigue, injury prevention. | Increased efficiency, predictive maintenance, real-time quality control. |

| Challenges | Cost, user acceptance, ethical concerns. | System complexity, cybersecurity risks, integration difficulties. |

| Impact on Workforce | Augments human roles, requires training on new devices. | Automates tasks, shifts workforce toward technical skillsets. |

| Example Applications | Lifting exoskeletons, AR glasses for assembly guidance. | Smart factories, robotic assembly lines, automated quality inspection. |

Which is better?

Human augmentation improves manufacturing efficiency by enhancing workers' physical and cognitive capabilities through wearable devices, exoskeletons, and augmented reality, leading to increased precision and reduced fatigue. Cyber-physical systems integrate computational algorithms with physical processes, enabling real-time monitoring, automation, and predictive maintenance that optimize production lines and minimize downtime. While human augmentation focuses on empowering individual operators, cyber-physical systems provide comprehensive automation and data-driven decision-making, making the choice dependent on the specific manufacturing environment and operational goals.

Connection

Human augmentation enhances worker capabilities in manufacturing by integrating wearable devices and exoskeletons with cyber-physical systems that monitor and control physical processes in real time. Cyber-physical systems leverage sensors, robotics, and IoT to create smart factories where augmented humans and machines collaborate seamlessly for optimized production efficiency. This fusion drives predictive maintenance, quality control, and adaptive automation, revolutionizing industrial workflows and safety standards.

Key Terms

**Cyber-Physical Systems:**

Cyber-Physical Systems (CPS) integrate computation, networking, and physical processes to enable real-time monitoring and control of complex environments such as smart grids, autonomous vehicles, and industrial automation. These systems rely on embedded sensors, actuators, and cyber components to enhance efficiency, safety, and precision in critical infrastructure. Explore the latest advancements in CPS to understand their transformative impact across various industries.

Sensors and Actuators

Cyber-physical systems integrate sensors and actuators to enable real-time interaction between computational elements and physical processes, enhancing automation and control across industries. Human augmentation relies on advanced sensors and actuators embedded in wearable or implantable devices to improve human capabilities such as strength, perception, and cognitive function. Explore the technological differences and applications of sensors and actuators in cyber-physical systems and human augmentation to understand their unique roles.

Embedded Computing

Cyber-physical systems integrate embedded computing with physical processes to enable real-time data processing and autonomous control, enhancing system reliability and efficiency. Human augmentation leverages embedded computing devices, such as wearable sensors and neural interfaces, to improve human capabilities and interactions with digital environments. Explore how advancements in embedded computing drive innovation in both cyber-physical systems and human augmentation for deeper insights.

Source and External Links

10 Examples of Cyber-Physical Systems | Claroty - Cyber-physical systems seamlessly integrate computation, control, networking, and analytics with the physical environment, impacting industries such as manufacturing and healthcare, and differ from typical IT devices by contributing directly to physical processes with unique security needs.

Cyber-Physical Systems (CPS) Explained - Splunk - CPS are systems that integrate sensing, computation, control, and networking into physical objects and infrastructure, enabling digital modeling and automation of physical systems, playing a crucial role in Industry 4.0 and advanced manufacturing through digital twins and centralized control.

Cyber-Physical Systems - a Concept Map - Ptolemy Project - CPS combine computation, networking, and physical processes with feedback loops, requiring integration of foundational abstractions from physical dynamics and computer science to create complex, highly dynamic engineered systems across various applications.

dowidth.com

dowidth.com