Generative design employs AI algorithms to explore numerous design alternatives based on specific constraints, promoting innovative solutions that maximize performance and minimize material usage. Topology optimization focuses on refining material layout within a defined space to achieve optimal structural efficiency, often resulting in lightweight, high-strength components. Discover how integrating generative design and topology optimization can revolutionize manufacturing processes.

Why it is important

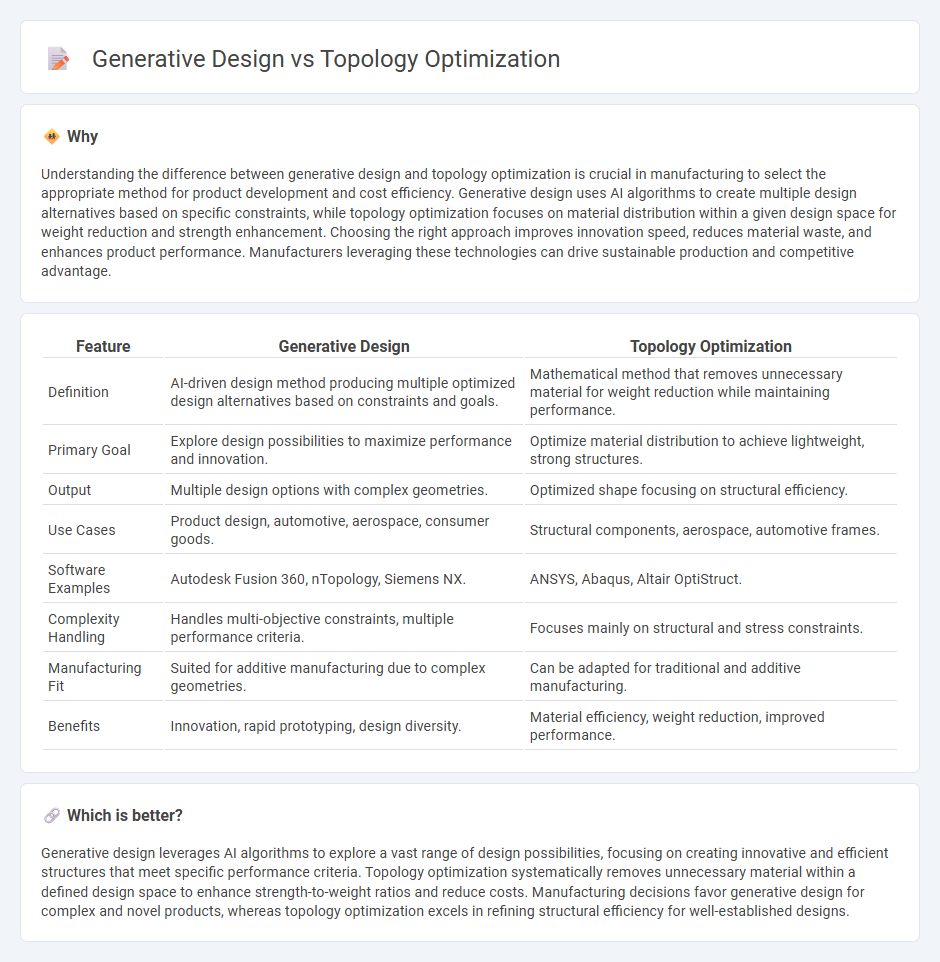

Understanding the difference between generative design and topology optimization is crucial in manufacturing to select the appropriate method for product development and cost efficiency. Generative design uses AI algorithms to create multiple design alternatives based on specific constraints, while topology optimization focuses on material distribution within a given design space for weight reduction and strength enhancement. Choosing the right approach improves innovation speed, reduces material waste, and enhances product performance. Manufacturers leveraging these technologies can drive sustainable production and competitive advantage.

Comparison Table

| Feature | Generative Design | Topology Optimization |

|---|---|---|

| Definition | AI-driven design method producing multiple optimized design alternatives based on constraints and goals. | Mathematical method that removes unnecessary material for weight reduction while maintaining performance. |

| Primary Goal | Explore design possibilities to maximize performance and innovation. | Optimize material distribution to achieve lightweight, strong structures. |

| Output | Multiple design options with complex geometries. | Optimized shape focusing on structural efficiency. |

| Use Cases | Product design, automotive, aerospace, consumer goods. | Structural components, aerospace, automotive frames. |

| Software Examples | Autodesk Fusion 360, nTopology, Siemens NX. | ANSYS, Abaqus, Altair OptiStruct. |

| Complexity Handling | Handles multi-objective constraints, multiple performance criteria. | Focuses mainly on structural and stress constraints. |

| Manufacturing Fit | Suited for additive manufacturing due to complex geometries. | Can be adapted for traditional and additive manufacturing. |

| Benefits | Innovation, rapid prototyping, design diversity. | Material efficiency, weight reduction, improved performance. |

Which is better?

Generative design leverages AI algorithms to explore a vast range of design possibilities, focusing on creating innovative and efficient structures that meet specific performance criteria. Topology optimization systematically removes unnecessary material within a defined design space to enhance strength-to-weight ratios and reduce costs. Manufacturing decisions favor generative design for complex and novel products, whereas topology optimization excels in refining structural efficiency for well-established designs.

Connection

Generative design and topology optimization both enhance manufacturing efficiency by leveraging algorithms to create optimized product geometries that reduce material usage and weight while maintaining strength. Generative design uses AI-driven iterations to explore a wide range of design alternatives based on performance criteria, whereas topology optimization mathematically refines material distribution within a given design space. Combining these methods enables manufacturers to produce lightweight, high-performance components with improved structural integrity and cost-effectiveness.

Key Terms

Design Constraints

Topology optimization strictly defines design constraints such as material distribution, load conditions, and boundary requirements to generate efficient, lightweight structures within narrowly specified performance limits. Generative design explores a broader set of constraints including manufacturing methods, multiple performance criteria, and aesthetic preferences, enabling the creation of diverse design alternatives through iterative algorithms. Explore how these methodologies handle design constraints to select the optimal approach for your engineering project.

Algorithmic Modeling

Topology optimization employs physics-based algorithms to distribute material efficiently within a defined space, aiming to maximize structural performance while minimizing weight. Generative design uses AI-driven algorithms to explore a wide array of design permutations, integrating constraints and performance goals to produce innovative and often non-intuitive solutions. Explore in-depth how algorithmic modeling transforms product development by blending these cutting-edge approaches.

Material Efficiency

Topology optimization enhances material efficiency by algorithmically removing unnecessary material within defined loads and constraints, leading to lightweight structures with maximal strength. Generative design expands on this by exploring numerous design variations, incorporating manufacturing constraints and performance goals to optimize both material use and functional complexity. Discover how these approaches transform engineering workflows and material conservation strategies.

Source and External Links

Topology Optimization 101: How to Use Algorithmic... - Uses algorithmic models and finite element analysis to remove unnecessary material within a given design space, optimizing the material layout for specific loads and constraints.

What is Topology Optimization? - A mathematical method that maximizes structural performance and minimizes material usage by algorithmically removing unnecessary material from a predefined design space, subject to specified constraints and objectives.

Topology optimization - A mathematical technique that optimizes the distribution of material within a design space for given loads and constraints, often leading to complex, organic shapes best suited for additive manufacturing.

dowidth.com

dowidth.com