Flexible manufacturing systems utilize automated machinery and adaptable workflows to efficiently produce a variety of products with minimal downtime, enhancing scalability and responsiveness. Custom manufacturing focuses on creating unique, tailor-made products designed to meet specific client requirements, often involving manual processes and specialized craftsmanship. Explore the differences and benefits of these manufacturing approaches to optimize your production strategy.

Why it is important

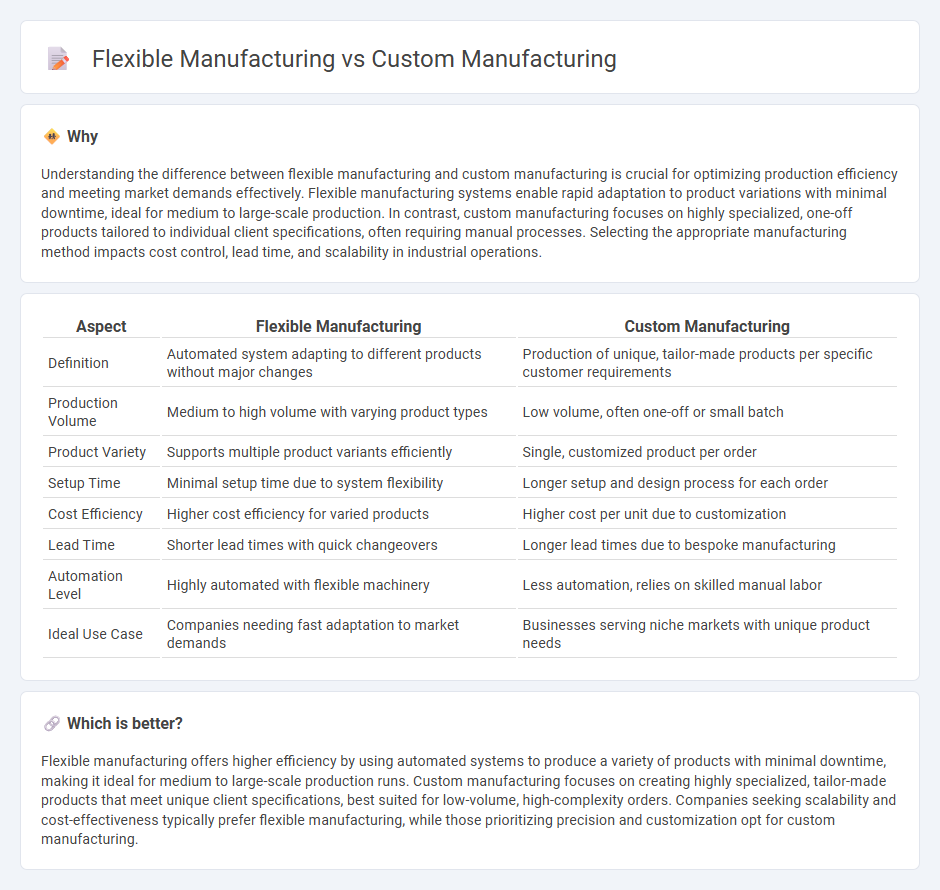

Understanding the difference between flexible manufacturing and custom manufacturing is crucial for optimizing production efficiency and meeting market demands effectively. Flexible manufacturing systems enable rapid adaptation to product variations with minimal downtime, ideal for medium to large-scale production. In contrast, custom manufacturing focuses on highly specialized, one-off products tailored to individual client specifications, often requiring manual processes. Selecting the appropriate manufacturing method impacts cost control, lead time, and scalability in industrial operations.

Comparison Table

| Aspect | Flexible Manufacturing | Custom Manufacturing |

|---|---|---|

| Definition | Automated system adapting to different products without major changes | Production of unique, tailor-made products per specific customer requirements |

| Production Volume | Medium to high volume with varying product types | Low volume, often one-off or small batch |

| Product Variety | Supports multiple product variants efficiently | Single, customized product per order |

| Setup Time | Minimal setup time due to system flexibility | Longer setup and design process for each order |

| Cost Efficiency | Higher cost efficiency for varied products | Higher cost per unit due to customization |

| Lead Time | Shorter lead times with quick changeovers | Longer lead times due to bespoke manufacturing |

| Automation Level | Highly automated with flexible machinery | Less automation, relies on skilled manual labor |

| Ideal Use Case | Companies needing fast adaptation to market demands | Businesses serving niche markets with unique product needs |

Which is better?

Flexible manufacturing offers higher efficiency by using automated systems to produce a variety of products with minimal downtime, making it ideal for medium to large-scale production runs. Custom manufacturing focuses on creating highly specialized, tailor-made products that meet unique client specifications, best suited for low-volume, high-complexity orders. Companies seeking scalability and cost-effectiveness typically prefer flexible manufacturing, while those prioritizing precision and customization opt for custom manufacturing.

Connection

Flexible manufacturing systems enable rapid adaptation to design changes and variable production volumes, directly supporting custom manufacturing's demand for tailored products. By integrating automated machinery and real-time data analytics, flexible manufacturing optimizes the customization process while reducing lead times and costs. This synergy enhances efficiency and responsiveness, allowing manufacturers to meet precise customer specifications without sacrificing scalability.

Key Terms

Production Volume

Custom manufacturing typically handles low production volumes with high variability, tailored to specific client requirements and unique product designs. Flexible manufacturing supports medium to high production volumes with adaptability to various product types and fast changeover times, optimizing efficiency and responsiveness to market demand. Explore more about how production volume influences manufacturing strategies and operational efficiency.

Adaptability

Custom manufacturing excels in adaptability by producing highly specialized products tailored to specific client needs, allowing for unique design variations and modifications. Flexible manufacturing systems leverage automation and modular equipment to rapidly switch between different product types, enhancing responsiveness to market changes with minimal downtime. Explore how these manufacturing approaches can optimize your production strategy for greater flexibility and efficiency.

Cost Structure

Custom manufacturing typically incurs higher fixed costs due to specialized equipment and skilled labor required for unique, low-volume production runs, resulting in less predictable cost structures. Flexible manufacturing systems enable more efficient resource utilization and reduced setup times, lowering variable costs and improving cost efficiency in diverse production scenarios. Explore detailed cost analyses and comparisons to understand which manufacturing approach aligns best with your business needs.

Source and External Links

Custom Manufacturing: Overcoming Challenges and Scaling With 3D Printing - Custom manufacturing designs and produces goods based on unique customer specifications, often using additive manufacturing (3D printing) to flexibly produce custom or small series parts such as bespoke jewelry or medical devices, enabling rapid scale and customization.

Browse Custom Manufacturing & Fabricating Categories on Thomasnet - Custom manufacturing delivers built-to-order parts and select services using specialized processes or equipment, supporting a wide range of industrial components through methods including welding, stamping, and thermoforming.

Custom Manufacturing: Processes, Benefits, and Applications - Custom manufacturing uses processes like additive manufacturing (3D printing) and subtractive manufacturing (CNC machining, EDM) to efficiently create unique parts that meet specific client needs in low quantities with precision and flexibility.

dowidth.com

dowidth.com