Flexible manufacturing systems integrate automated machinery and computer-controlled processes to efficiently handle a variety of products with minimal downtime. Agile manufacturing emphasizes rapid adaptation to market changes by leveraging modular production techniques and real-time data analytics. Explore the key differences and benefits of flexible and agile manufacturing to enhance your production strategy.

Why it is important

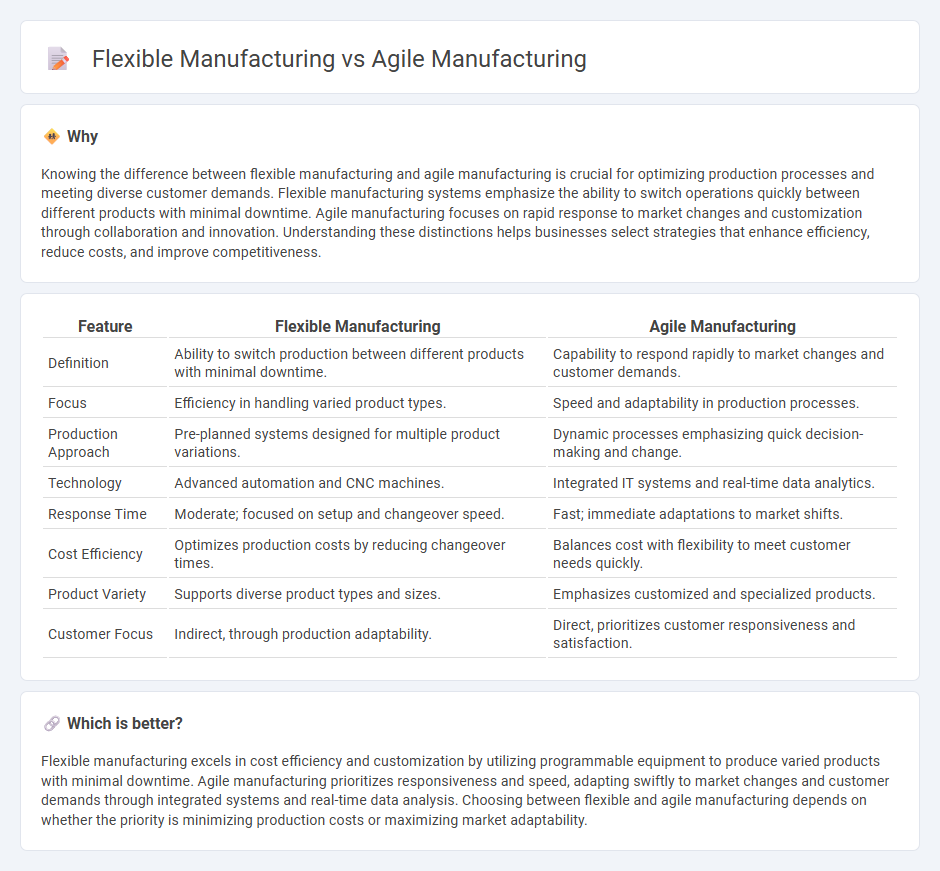

Knowing the difference between flexible manufacturing and agile manufacturing is crucial for optimizing production processes and meeting diverse customer demands. Flexible manufacturing systems emphasize the ability to switch operations quickly between different products with minimal downtime. Agile manufacturing focuses on rapid response to market changes and customization through collaboration and innovation. Understanding these distinctions helps businesses select strategies that enhance efficiency, reduce costs, and improve competitiveness.

Comparison Table

| Feature | Flexible Manufacturing | Agile Manufacturing |

|---|---|---|

| Definition | Ability to switch production between different products with minimal downtime. | Capability to respond rapidly to market changes and customer demands. |

| Focus | Efficiency in handling varied product types. | Speed and adaptability in production processes. |

| Production Approach | Pre-planned systems designed for multiple product variations. | Dynamic processes emphasizing quick decision-making and change. |

| Technology | Advanced automation and CNC machines. | Integrated IT systems and real-time data analytics. |

| Response Time | Moderate; focused on setup and changeover speed. | Fast; immediate adaptations to market shifts. |

| Cost Efficiency | Optimizes production costs by reducing changeover times. | Balances cost with flexibility to meet customer needs quickly. |

| Product Variety | Supports diverse product types and sizes. | Emphasizes customized and specialized products. |

| Customer Focus | Indirect, through production adaptability. | Direct, prioritizes customer responsiveness and satisfaction. |

Which is better?

Flexible manufacturing excels in cost efficiency and customization by utilizing programmable equipment to produce varied products with minimal downtime. Agile manufacturing prioritizes responsiveness and speed, adapting swiftly to market changes and customer demands through integrated systems and real-time data analysis. Choosing between flexible and agile manufacturing depends on whether the priority is minimizing production costs or maximizing market adaptability.

Connection

Flexible manufacturing and agile manufacturing are connected through their shared emphasis on adaptability and rapid response to changing market demands. Flexible manufacturing systems enable quick reconfiguration of production processes to accommodate different products or variations, while agile manufacturing extends this by integrating cross-functional collaboration and real-time information flow to enhance overall responsiveness. Both methodologies aim to reduce lead times, increase customization, and improve efficiency in dynamic production environments.

Key Terms

Agile Manufacturing: responsiveness, integration, customization

Agile manufacturing emphasizes rapid responsiveness to market changes, seamless integration of processes, and high levels of product customization to meet specific customer needs. This approach leverages advanced technologies and cross-functional teams to adapt quickly, ensuring minimal lead times and enhanced customer satisfaction. Explore how agile manufacturing can transform your production efficiency and competitiveness.

Flexible Manufacturing: adaptability, reconfigurability, automation

Flexible manufacturing systems emphasize adaptability through modular design, enabling quick reconfigurations to accommodate varying product types and volumes. High levels of automation enhance efficiency, reducing setup times and labor costs while maintaining precision. Explore how flexible manufacturing drives competitive advantage in dynamic production environments.

Rapid Response

Agile manufacturing emphasizes rapid response by integrating cross-functional teams and real-time data to quickly adapt to market changes and customer demands. Flexible manufacturing relies on versatile machinery and reconfigurable production lines to switch efficiently between different products with minimal downtime. Explore the differences and benefits of agile and flexible manufacturing for your business needs.

Source and External Links

What Is Agile Manufacturing? Lean vs. Agile - Agile manufacturing is a methodology centered on rapid customer response by leveraging speed and flexibility as key competitive advantages, often building on lean manufacturing foundations such as small batch production and continuous improvement.

Agile Manufacturing: Benefits, Challenges, and Key Technologies - Agile manufacturing prioritizes responsiveness and customization to customer needs, exemplified by Dell's model that reduces inventory and shortens cycle times while boosting quality and productivity.

Agile manufacturing - Wikipedia - Agile manufacturing enables companies to swiftly adapt to market changes and customer demands by maintaining quality and cost control, combining principles of lean manufacturing with additional focus on flexibility, collaboration, and real-time responsiveness.

dowidth.com

dowidth.com