Microfactories emphasize compact, flexible production units optimized for rapid prototyping and small-batch manufacturing, leveraging automation and digital tools to enhance efficiency. Job shop manufacturing focuses on customized, low-volume production with skilled labor handling diverse tasks, suited for complex and varied product demands. Explore the key differences and benefits of microfactory versus job shop manufacturing to determine the best fit for your production needs.

Why it is important

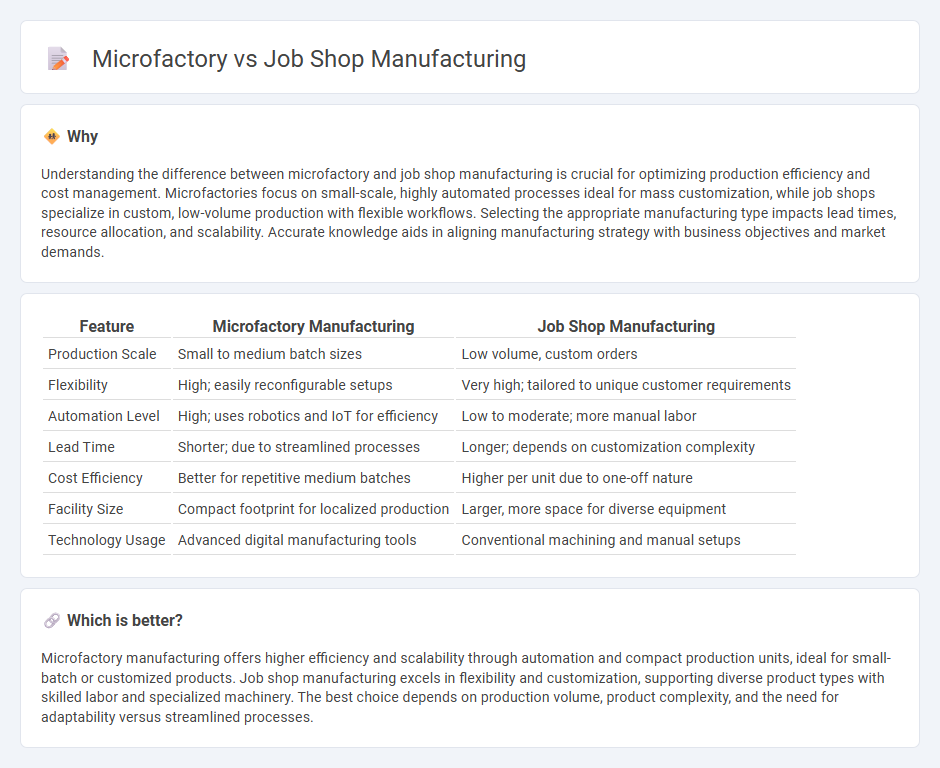

Understanding the difference between microfactory and job shop manufacturing is crucial for optimizing production efficiency and cost management. Microfactories focus on small-scale, highly automated processes ideal for mass customization, while job shops specialize in custom, low-volume production with flexible workflows. Selecting the appropriate manufacturing type impacts lead times, resource allocation, and scalability. Accurate knowledge aids in aligning manufacturing strategy with business objectives and market demands.

Comparison Table

| Feature | Microfactory Manufacturing | Job Shop Manufacturing |

|---|---|---|

| Production Scale | Small to medium batch sizes | Low volume, custom orders |

| Flexibility | High; easily reconfigurable setups | Very high; tailored to unique customer requirements |

| Automation Level | High; uses robotics and IoT for efficiency | Low to moderate; more manual labor |

| Lead Time | Shorter; due to streamlined processes | Longer; depends on customization complexity |

| Cost Efficiency | Better for repetitive medium batches | Higher per unit due to one-off nature |

| Facility Size | Compact footprint for localized production | Larger, more space for diverse equipment |

| Technology Usage | Advanced digital manufacturing tools | Conventional machining and manual setups |

Which is better?

Microfactory manufacturing offers higher efficiency and scalability through automation and compact production units, ideal for small-batch or customized products. Job shop manufacturing excels in flexibility and customization, supporting diverse product types with skilled labor and specialized machinery. The best choice depends on production volume, product complexity, and the need for adaptability versus streamlined processes.

Connection

Microfactory and job shop manufacturing both focus on producing customized, low-volume products through flexible, small-scale operations. Microfactories integrate advanced automation and digital technologies to enhance the efficiency and responsiveness of job shop processes. This synergy allows manufacturers to quickly adapt to changing customer demands while maintaining high-quality craftsmanship.

Key Terms

**Job Shop Manufacturing:**

Job Shop Manufacturing specializes in producing customized, small-batch products with high variability in design, leveraging skilled labor and flexible equipment to meet specific client requirements. This manufacturing system emphasizes adaptability and precision over mass production, making it ideal for complex, low-volume orders across various industries. Explore further to understand how Job Shop Manufacturing can optimize your production needs with tailored solutions.

Customization

Job shop manufacturing excels in customization by producing small batches of highly specialized products tailored to specific customer requirements, leveraging skilled labor and versatile machinery. Microfactories integrate advanced digital technologies and automation to offer rapid, flexible customization for local markets while minimizing lead times and operational costs. Discover how these approaches transform customization strategies and drive competitive advantage in modern manufacturing.

Batch Production

Batch production in job shop manufacturing involves producing small quantities of custom products with high flexibility, utilizing skilled labor and general-purpose machines to handle diverse tasks. Microfactories streamline batch production by integrating advanced automation and modular layouts, enabling rapid changeovers and reduced lead times for customized orders. Explore the differences and benefits of each approach to optimize your batch production strategy.

Source and External Links

What Is a Job Shop? Job Shop Manufacturing Explained - A job shop is a specialized manufacturing facility that produces custom parts or assemblies in small quantities, serving industries like aerospace, custom machinery, and metal fabrication.

Job Shop Manufacturing: The Detailed Guide - Job shop manufacturing handles small, made-to-order batches using flexible, general-purpose equipment and skilled workers to manage a high variety of products.

Job Shop Manufacturing: Everything You Need to Know - Job shop production allows for personalized, low-volume items--such as custom wooden eyeglasses--where each order follows a unique process from design to final assembly.

dowidth.com

dowidth.com