Industrial metaverse integrates virtual reality and digital twins to revolutionize manufacturing processes, offering immersive simulations and real-time collaboration. Product Lifecycle Management (PLM) systems focus on managing product data and workflows from design to disposal, ensuring efficient and traceable production cycles. Explore how these technologies converge to enhance innovation and operational efficiency in modern manufacturing.

Why it is important

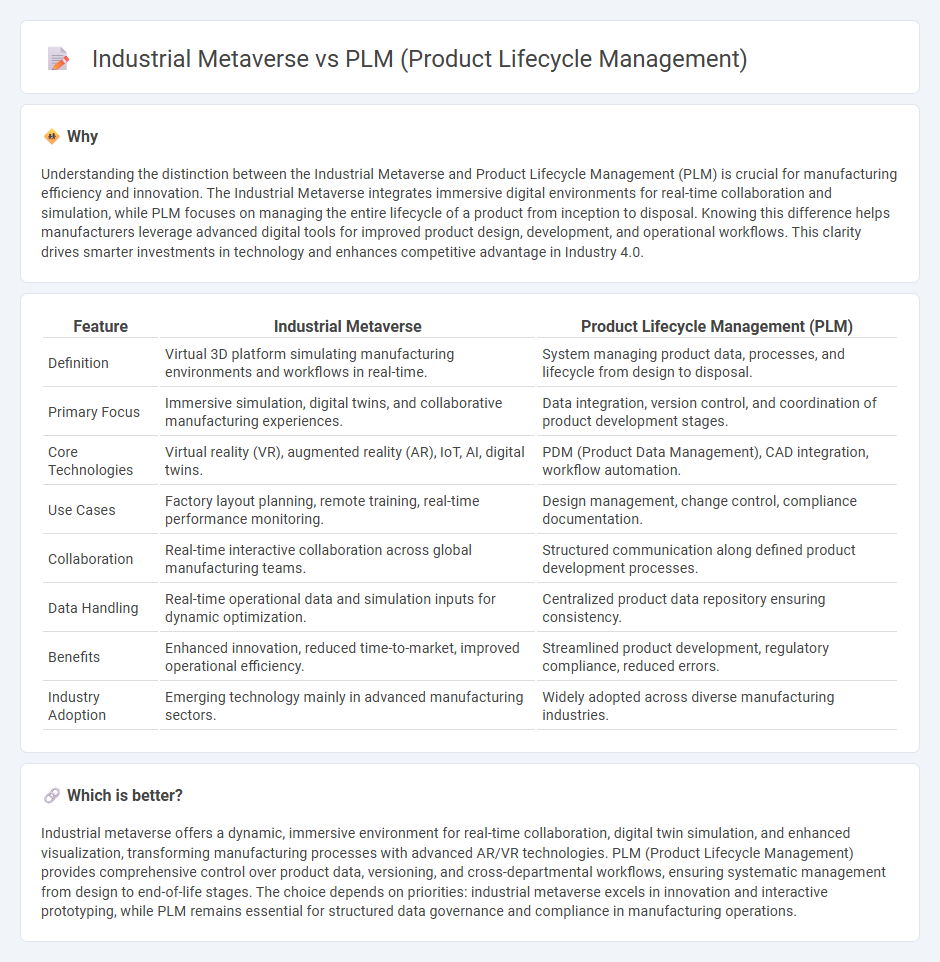

Understanding the distinction between the Industrial Metaverse and Product Lifecycle Management (PLM) is crucial for manufacturing efficiency and innovation. The Industrial Metaverse integrates immersive digital environments for real-time collaboration and simulation, while PLM focuses on managing the entire lifecycle of a product from inception to disposal. Knowing this difference helps manufacturers leverage advanced digital tools for improved product design, development, and operational workflows. This clarity drives smarter investments in technology and enhances competitive advantage in Industry 4.0.

Comparison Table

| Feature | Industrial Metaverse | Product Lifecycle Management (PLM) |

|---|---|---|

| Definition | Virtual 3D platform simulating manufacturing environments and workflows in real-time. | System managing product data, processes, and lifecycle from design to disposal. |

| Primary Focus | Immersive simulation, digital twins, and collaborative manufacturing experiences. | Data integration, version control, and coordination of product development stages. |

| Core Technologies | Virtual reality (VR), augmented reality (AR), IoT, AI, digital twins. | PDM (Product Data Management), CAD integration, workflow automation. |

| Use Cases | Factory layout planning, remote training, real-time performance monitoring. | Design management, change control, compliance documentation. |

| Collaboration | Real-time interactive collaboration across global manufacturing teams. | Structured communication along defined product development processes. |

| Data Handling | Real-time operational data and simulation inputs for dynamic optimization. | Centralized product data repository ensuring consistency. |

| Benefits | Enhanced innovation, reduced time-to-market, improved operational efficiency. | Streamlined product development, regulatory compliance, reduced errors. |

| Industry Adoption | Emerging technology mainly in advanced manufacturing sectors. | Widely adopted across diverse manufacturing industries. |

Which is better?

Industrial metaverse offers a dynamic, immersive environment for real-time collaboration, digital twin simulation, and enhanced visualization, transforming manufacturing processes with advanced AR/VR technologies. PLM (Product Lifecycle Management) provides comprehensive control over product data, versioning, and cross-departmental workflows, ensuring systematic management from design to end-of-life stages. The choice depends on priorities: industrial metaverse excels in innovation and interactive prototyping, while PLM remains essential for structured data governance and compliance in manufacturing operations.

Connection

The Industrial Metaverse integrates digital twins and immersive simulation, enhancing Product Lifecycle Management (PLM) by enabling real-time collaboration across design, production, and maintenance phases. This connection accelerates decision-making, reduces prototyping costs, and optimizes supply chain workflows. Leveraging cloud computing and IoT data, the synergy between Industrial Metaverse and PLM drives innovation and efficiency in smart manufacturing environments.

Key Terms

Digital Twin

PLM (Product Lifecycle Management) integrates data, processes, and people to manage a product's entire lifecycle, enhancing collaboration and efficiency through digital twin technology that simulates real-time product performance and lifecycle stages. The industrial metaverse extends this concept by creating immersive, interconnected virtual environments where digital twins interact within a broader ecosystem, enabling advanced simulations and real-time decision-making across multiple industries. Explore how digital twin advancements in PLM and the industrial metaverse are revolutionizing product development and operational strategies.

Data Integration

PLM (Product Lifecycle Management) centralizes data integration by managing product-related information across design, manufacturing, and maintenance phases, ensuring consistency and traceability. The industrial metaverse expands this concept by creating immersive, interconnected digital twins and virtual environments that integrate real-time data from multiple sources, fostering collaborative innovation and predictive analytics. Explore how these technologies transform data integration for enhanced industrial efficiency and innovation.

Virtual Collaboration

Product Lifecycle Management (PLM) optimizes product design, development, and manufacturing workflows through centralized data management and real-time collaboration tools, enhancing efficiency and reducing errors. The Industrial Metaverse extends these capabilities by creating immersive, interactive virtual environments that enable teams to visualize, simulate, and modify products in 3D space, fostering deeper collaboration and innovation across global locations. Explore how integrating PLM with the Industrial Metaverse can revolutionize virtual collaboration in your industry.

Source and External Links

Product lifecycle - PLM is the process managing the entire lifecycle of a product from inception through design, manufacture, service, and disposal, integrating people, data, and processes with a central product information system.

What Is PLM Software? | Product Lifecycle Management - PLM software manages all information and processes throughout a product's lifecycle across global supply chains, enabling digital foundation and unified product value chain for faster innovation and better product management.

Product Life Cycle Management (PLM) Explained - PLM coordinates activities across product design, manufacturing, and distribution phases, connecting areas such as development, marketing, service, and suppliers to optimize product lifecycle management.

dowidth.com

dowidth.com