Biofabrication employs additive processes to create complex, biologically inspired structures with high precision, using living cells and biomaterials. Conventional machining relies on subtractive methods, cutting away material from solid blocks to shape parts, often limited by tool accessibility and material waste. Explore deeper insights into how biofabrication is revolutionizing manufacturing with sustainable and customizable solutions.

Why it is important

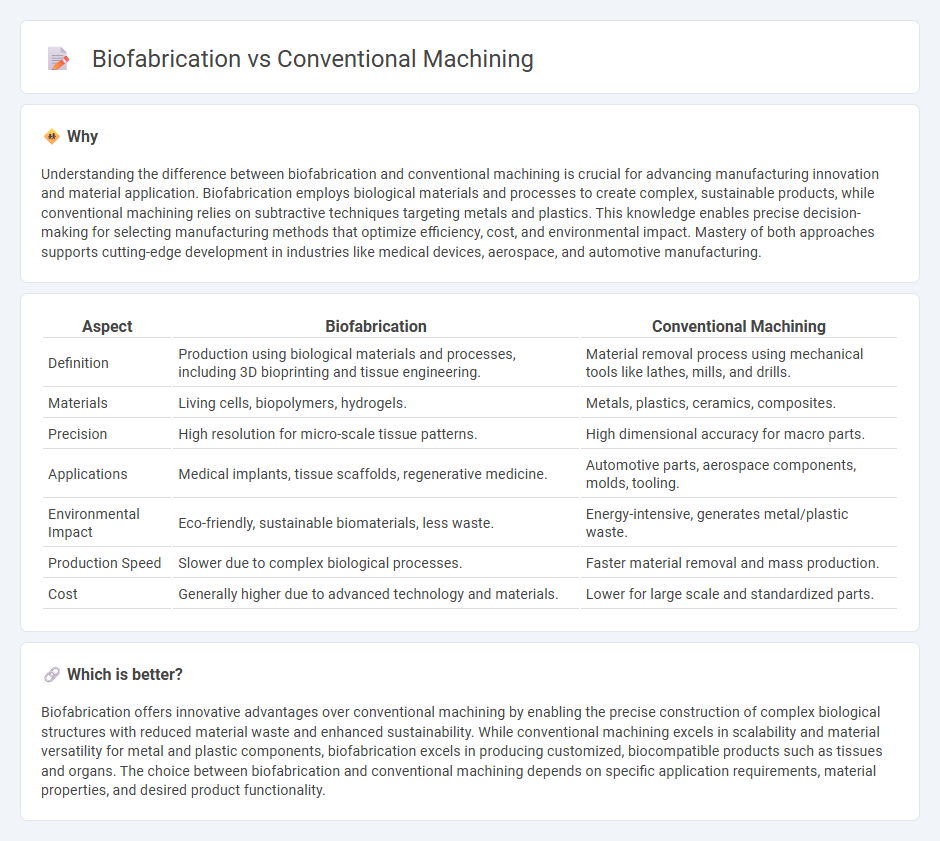

Understanding the difference between biofabrication and conventional machining is crucial for advancing manufacturing innovation and material application. Biofabrication employs biological materials and processes to create complex, sustainable products, while conventional machining relies on subtractive techniques targeting metals and plastics. This knowledge enables precise decision-making for selecting manufacturing methods that optimize efficiency, cost, and environmental impact. Mastery of both approaches supports cutting-edge development in industries like medical devices, aerospace, and automotive manufacturing.

Comparison Table

| Aspect | Biofabrication | Conventional Machining |

|---|---|---|

| Definition | Production using biological materials and processes, including 3D bioprinting and tissue engineering. | Material removal process using mechanical tools like lathes, mills, and drills. |

| Materials | Living cells, biopolymers, hydrogels. | Metals, plastics, ceramics, composites. |

| Precision | High resolution for micro-scale tissue patterns. | High dimensional accuracy for macro parts. |

| Applications | Medical implants, tissue scaffolds, regenerative medicine. | Automotive parts, aerospace components, molds, tooling. |

| Environmental Impact | Eco-friendly, sustainable biomaterials, less waste. | Energy-intensive, generates metal/plastic waste. |

| Production Speed | Slower due to complex biological processes. | Faster material removal and mass production. |

| Cost | Generally higher due to advanced technology and materials. | Lower for large scale and standardized parts. |

Which is better?

Biofabrication offers innovative advantages over conventional machining by enabling the precise construction of complex biological structures with reduced material waste and enhanced sustainability. While conventional machining excels in scalability and material versatility for metal and plastic components, biofabrication excels in producing customized, biocompatible products such as tissues and organs. The choice between biofabrication and conventional machining depends on specific application requirements, material properties, and desired product functionality.

Connection

Biofabrication integrates innovative techniques such as 3D bioprinting with conventional machining processes to create complex, functional biological structures. Conventional machining provides precision tools and methods essential for fabricating molds, scaffolds, and support components used in biofabrication. This synergy enhances manufacturing capabilities in biomedical engineering, leading to advancements in tissue engineering and regenerative medicine.

Key Terms

Subtractive manufacturing

Subtractive manufacturing in conventional machining involves removing material from a solid block using tools like CNC mills or lathes to achieve precise shapes and tolerances. In biofabrication, subtractive methods sculpt biological materials, such as hydrogels or tissue scaffolds, to create structures compatible with living tissues. Explore deeper insights into the contrasting techniques and applications of subtractive processes in these innovative fields.

Additive manufacturing

Additive manufacturing in conventional machining builds components layer by layer through processes like CNC machining, offering precision and material versatility critical in automotive and aerospace sectors. In biofabrication, additive manufacturing enables the creation of complex tissue structures by depositing bioinks containing living cells, revolutionizing regenerative medicine and personalized healthcare. Explore how these advancements in additive manufacturing transform industrial production and biomedical innovation.

Material biocompatibility

Conventional machining employs subtractive methods using metals and polymers, which often require extensive surface treatments to improve biocompatibility for medical implants. Biofabrication utilizes additive manufacturing with bioinks composed of cells and biocompatible materials like hydrogels, enabling the creation of tissue-like structures with enhanced biological integration. Explore further to understand how these approaches impact scaffold design and patient outcomes.

Source and External Links

Conventional Machining (College of Engineering, Mechanical Engineering Department) - Conventional machining is a manufacturing process where a sharp cutting tool directly cuts away material to produce the desired part shape, involving shear deformation to form chips and creating the final geometry after processes like casting or forging.

Machining - Wikipedia - Conventional machining includes traditional operations such as turning, boring, drilling, and threading, where machine tools shape the workpiece by direct contact and relative motion.

CNC Machining vs. Conventional Machining - EMC Precision - Conventional machining requires a human operator to manually control machining tools like mills, lathes, and drills, directing tool contact with raw materials to achieve the final product.

dowidth.com

dowidth.com