Adaptive machining leverages real-time sensor feedback and advanced control systems to dynamically adjust cutting parameters, enhancing precision and reducing material waste in manufacturing processes. Additive manufacturing builds products layer by layer using materials such as metals, plastics, or ceramics, allowing for complex geometries and rapid prototyping without the need for extensive tooling. Explore the advantages and applications of both adaptive machining and additive manufacturing to optimize production efficiency and innovation.

Why it is important

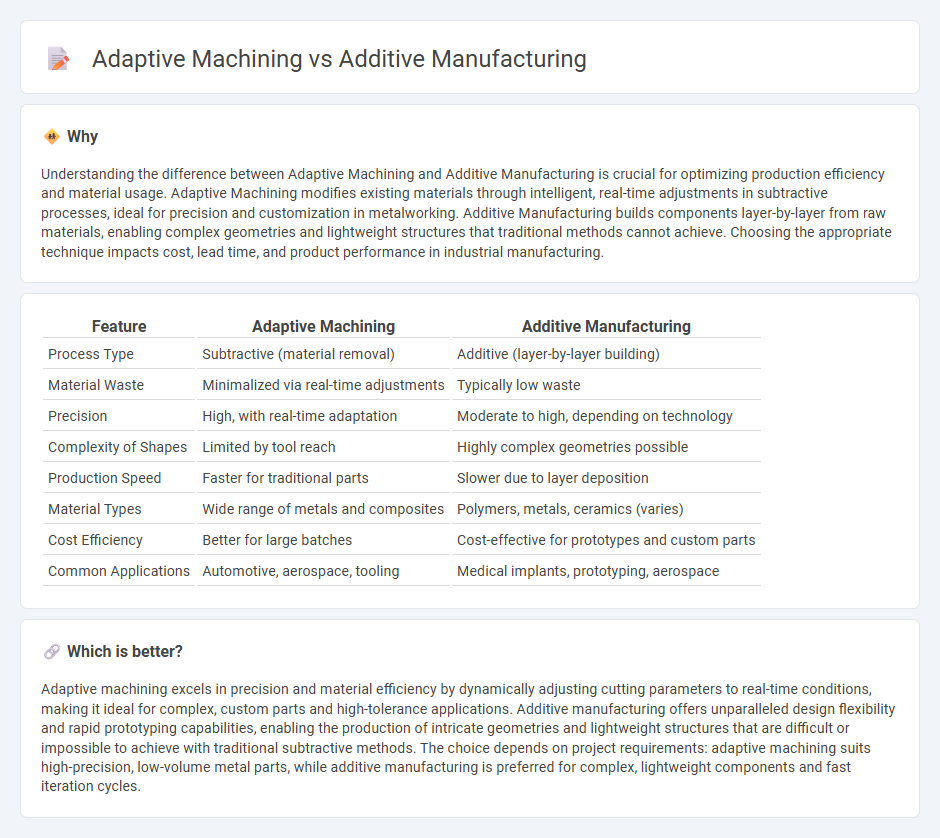

Understanding the difference between Adaptive Machining and Additive Manufacturing is crucial for optimizing production efficiency and material usage. Adaptive Machining modifies existing materials through intelligent, real-time adjustments in subtractive processes, ideal for precision and customization in metalworking. Additive Manufacturing builds components layer-by-layer from raw materials, enabling complex geometries and lightweight structures that traditional methods cannot achieve. Choosing the appropriate technique impacts cost, lead time, and product performance in industrial manufacturing.

Comparison Table

| Feature | Adaptive Machining | Additive Manufacturing |

|---|---|---|

| Process Type | Subtractive (material removal) | Additive (layer-by-layer building) |

| Material Waste | Minimalized via real-time adjustments | Typically low waste |

| Precision | High, with real-time adaptation | Moderate to high, depending on technology |

| Complexity of Shapes | Limited by tool reach | Highly complex geometries possible |

| Production Speed | Faster for traditional parts | Slower due to layer deposition |

| Material Types | Wide range of metals and composites | Polymers, metals, ceramics (varies) |

| Cost Efficiency | Better for large batches | Cost-effective for prototypes and custom parts |

| Common Applications | Automotive, aerospace, tooling | Medical implants, prototyping, aerospace |

Which is better?

Adaptive machining excels in precision and material efficiency by dynamically adjusting cutting parameters to real-time conditions, making it ideal for complex, custom parts and high-tolerance applications. Additive manufacturing offers unparalleled design flexibility and rapid prototyping capabilities, enabling the production of intricate geometries and lightweight structures that are difficult or impossible to achieve with traditional subtractive methods. The choice depends on project requirements: adaptive machining suits high-precision, low-volume metal parts, while additive manufacturing is preferred for complex, lightweight components and fast iteration cycles.

Connection

Adaptive machining enhances manufacturing precision by using real-time data to adjust cutting parameters, which complements additive manufacturing's layer-by-layer construction method by allowing tailored post-processing for complex geometries. Integration of both processes results in improved surface finishes and tighter tolerances, crucial for aerospace and medical device production. This synergy accelerates prototyping and custom part production, reducing lead times and material waste.

Key Terms

Layer-by-layer fabrication (Additive manufacturing)

Layer-by-layer fabrication in additive manufacturing involves building parts by sequentially depositing material, enabling complex geometries and reduced waste compared to traditional subtractive processes. This technique contrasts with adaptive machining, which modifies existing materials through controlled cutting or milling to achieve precision and surface finish. Explore the distinct advantages of these technologies and their impact on modern manufacturing systems.

Real-time feedback control (Adaptive machining)

Adaptive machining leverages real-time feedback control to continuously monitor and adjust machining parameters, enhancing precision and reducing errors during the manufacturing process. In contrast, additive manufacturing builds components layer-by-layer but often lacks such dynamic, real-time adjustments, relying instead on pre-set digital models and post-process inspections. Explore deeper insights into how real-time feedback control revolutionizes adaptive machining and its impact on manufacturing accuracy.

Toolpath adjustment

Additive manufacturing builds objects layer by layer based on pre-defined CAD models, with limited real-time toolpath adjustments. Adaptive machining continuously modifies toolpaths during subtractive processes by analyzing sensor data to optimize cutting efficiency and accommodate material inconsistencies. Explore the benefits and applications of dynamic toolpath control in modern manufacturing techniques.

Source and External Links

Additive manufacturing, explained | MIT Sloan - Additive manufacturing builds objects layer by layer from digital designs, typically using 3D printing, and has evolved from rapid prototyping to creating functional products across industries.

Additive manufacturing | NIST - Additive manufacturing or 3D printing fabricates parts layer-by-layer from digital models with materials like metal, plastic, or ceramics, enabling complex designs and reducing waste compared to traditional methods.

What Is Additive Manufacturing? | 3D Printing Simulation Software - Industrial additive manufacturing creates 3D objects from CAD models by layering material in various processes such as powder bed fusion and material extrusion, supporting rapid prototyping and production parts.

dowidth.com

dowidth.com