Flexible manufacturing systems (FMS) utilize automated machinery and robotics for high-volume production with quick changeovers, maximizing efficiency and reducing downtime. Job shop manufacturing focuses on custom, small-batch production with skilled labor handling diverse, complex tasks tailored to specific client needs. Explore the benefits and applications of both manufacturing types to determine the best fit for your production goals.

Why it is important

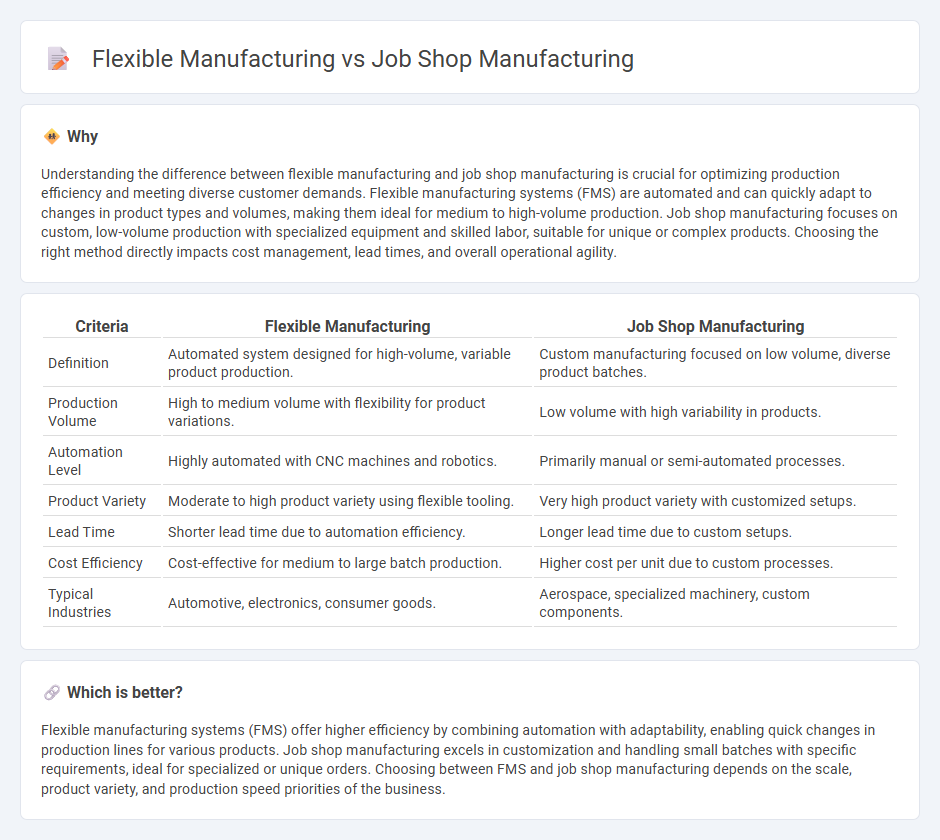

Understanding the difference between flexible manufacturing and job shop manufacturing is crucial for optimizing production efficiency and meeting diverse customer demands. Flexible manufacturing systems (FMS) are automated and can quickly adapt to changes in product types and volumes, making them ideal for medium to high-volume production. Job shop manufacturing focuses on custom, low-volume production with specialized equipment and skilled labor, suitable for unique or complex products. Choosing the right method directly impacts cost management, lead times, and overall operational agility.

Comparison Table

| Criteria | Flexible Manufacturing | Job Shop Manufacturing |

|---|---|---|

| Definition | Automated system designed for high-volume, variable product production. | Custom manufacturing focused on low volume, diverse product batches. |

| Production Volume | High to medium volume with flexibility for product variations. | Low volume with high variability in products. |

| Automation Level | Highly automated with CNC machines and robotics. | Primarily manual or semi-automated processes. |

| Product Variety | Moderate to high product variety using flexible tooling. | Very high product variety with customized setups. |

| Lead Time | Shorter lead time due to automation efficiency. | Longer lead time due to custom setups. |

| Cost Efficiency | Cost-effective for medium to large batch production. | Higher cost per unit due to custom processes. |

| Typical Industries | Automotive, electronics, consumer goods. | Aerospace, specialized machinery, custom components. |

Which is better?

Flexible manufacturing systems (FMS) offer higher efficiency by combining automation with adaptability, enabling quick changes in production lines for various products. Job shop manufacturing excels in customization and handling small batches with specific requirements, ideal for specialized or unique orders. Choosing between FMS and job shop manufacturing depends on the scale, product variety, and production speed priorities of the business.

Connection

Flexible manufacturing and job shop manufacturing are connected through their emphasis on adaptability and customization in production processes. Both systems utilize versatile machinery and skilled labor to efficiently handle small batch sizes and varied product designs. This connection enables manufacturers to respond quickly to changing market demands while maintaining cost-effective operations.

Key Terms

**Job Shop Manufacturing:**

Job shop manufacturing specializes in custom, small-batch production with high variability, utilizing general-purpose machines and skilled labor to handle diverse product designs. This method maximizes flexibility by organizing work around specific jobs rather than continuous flow processes, ideal for bespoke or low-volume orders requiring precision. Discover how job shop manufacturing optimizes efficiency and customization in complex production environments.

Customization

Job shop manufacturing excels in customization by producing small batches of highly specialized products tailored to specific customer requirements, utilizing skilled labor and versatile machinery for varied tasks. Flexible manufacturing systems (FMS) balance customization with efficiency, allowing rapid adjustments in production schedules and tooling to meet changing customer demands while maintaining higher volume outputs. Explore the advantages of each approach to determine the best fit for your customization needs.

Batch Production

Job shop manufacturing specializes in customized, small-batch production with high flexibility, utilizing skilled labor and general-purpose machines to handle diverse product specifications. Flexible manufacturing systems (FMS) automate batch production through computer-controlled machinery, enabling quick transitions between product types while maintaining consistent quality and efficiency in medium to large batch sizes. Explore detailed comparisons and industry applications to optimize your batch production strategy.

Source and External Links

What Is a Job Shop? Job Shop Manufacturing Explained - MRPeasy - A job shop is a specialized manufacturing facility producing custom parts or assemblies in small quantities, commonly serving industries like custom machinery, tool and die making, prototyping, aerospace components, and automotive customization.

Job Shop Manufacturing: The Detailed Guide - Deskera - Job shop manufacturing handles small, made-to-order batches with high variety and low volume, typically seen in engineer-to-order and custom production units such as machine, mold, and tool shops, as well as bespoke woodworking and repair companies.

Job Shop Manufacturing: Everything You Need to Know - Katana MRP - Job shop manufacturing involves producing diverse, customized products like eyeglasses where each order is tailored through steps like design selection and material preparation, emphasizing flexible, small-batch production based on customer specifications.

dowidth.com

dowidth.com