Cobotics enhances manufacturing efficiency by enabling humans and robots to collaborate directly, improving precision and safety on the production floor. Artificial intelligence drives automation through advanced data analysis, predictive maintenance, and adaptive control systems, significantly reducing downtime and operational costs. Explore how integrating cobotics and AI transforms modern manufacturing processes for unprecedented productivity.

Why it is important

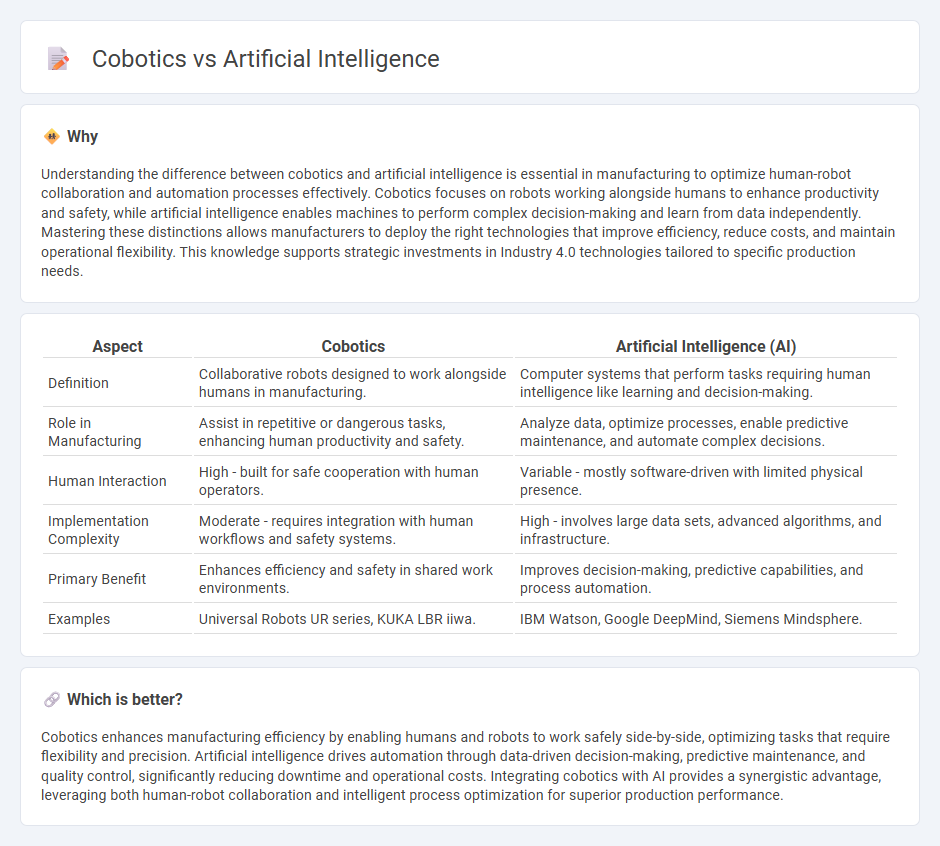

Understanding the difference between cobotics and artificial intelligence is essential in manufacturing to optimize human-robot collaboration and automation processes effectively. Cobotics focuses on robots working alongside humans to enhance productivity and safety, while artificial intelligence enables machines to perform complex decision-making and learn from data independently. Mastering these distinctions allows manufacturers to deploy the right technologies that improve efficiency, reduce costs, and maintain operational flexibility. This knowledge supports strategic investments in Industry 4.0 technologies tailored to specific production needs.

Comparison Table

| Aspect | Cobotics | Artificial Intelligence (AI) |

|---|---|---|

| Definition | Collaborative robots designed to work alongside humans in manufacturing. | Computer systems that perform tasks requiring human intelligence like learning and decision-making. |

| Role in Manufacturing | Assist in repetitive or dangerous tasks, enhancing human productivity and safety. | Analyze data, optimize processes, enable predictive maintenance, and automate complex decisions. |

| Human Interaction | High - built for safe cooperation with human operators. | Variable - mostly software-driven with limited physical presence. |

| Implementation Complexity | Moderate - requires integration with human workflows and safety systems. | High - involves large data sets, advanced algorithms, and infrastructure. |

| Primary Benefit | Enhances efficiency and safety in shared work environments. | Improves decision-making, predictive capabilities, and process automation. |

| Examples | Universal Robots UR series, KUKA LBR iiwa. | IBM Watson, Google DeepMind, Siemens Mindsphere. |

Which is better?

Cobotics enhances manufacturing efficiency by enabling humans and robots to work safely side-by-side, optimizing tasks that require flexibility and precision. Artificial intelligence drives automation through data-driven decision-making, predictive maintenance, and quality control, significantly reducing downtime and operational costs. Integrating cobotics with AI provides a synergistic advantage, leveraging both human-robot collaboration and intelligent process optimization for superior production performance.

Connection

Cobotics integrates collaborative robots with artificial intelligence (AI) to enhance manufacturing processes by enabling real-time decision-making and adaptive automation. AI-driven cobots improve precision, flexibility, and efficiency by learning workflows and interacting safely with human workers on the factory floor. This synergy accelerates production cycles, reduces errors, and optimizes resource allocation in modern smart manufacturing environments.

Key Terms

Automation

Artificial intelligence (AI) drives automation through machine learning and neural networks, enabling systems to perform complex tasks autonomously. Cobotics integrates human collaboration with robotic automation, enhancing flexibility and safety in workflows by allowing robots to work alongside humans. Explore how AI and cobotics together revolutionize automation in various industries.

Human-robot collaboration

Artificial intelligence (AI) enhances human-robot collaboration by enabling robots to learn, adapt, and make autonomous decisions, improving efficiency in complex tasks. Cobotics centers on the direct interaction between humans and collaborative robots (cobots), designed to work safely alongside workers in shared environments. Explore the latest advances in AI-powered cobotics to understand how this synergy transforms industrial productivity.

Machine learning

Machine learning drives artificial intelligence by enabling systems to autonomously learn from data and improve performance without explicit programming. In cobotics, machine learning optimizes human-robot collaboration, enhancing safety, adaptability, and efficiency in shared workspaces. Explore how machine learning transforms both AI and cobotic systems by visiting our detailed analysis.

Source and External Links

What Is Artificial Intelligence (AI)? - Artificial intelligence is a set of technologies enabling computers to perform advanced functions like reasoning, learning, analyzing data, and understanding language--often by leveraging machine learning and deep learning techniques to process and derive insights from large datasets.

Artificial intelligence - Wikipedia - Artificial intelligence (AI) refers to the capability of computational systems to perform tasks traditionally requiring human intelligence, such as learning, reasoning, problem-solving, perception, and decision-making, and is a broad field encompassing research in computer science and related disciplines.

Artificial Intelligence (AI): What it is and why it matters - SAS - AI enables machines to learn from experience, adapt to new inputs, and perform human-like tasks by combining large amounts of data with fast processing and intelligent algorithms, leading to applications like machine learning, neural networks, and natural language processing.

dowidth.com

dowidth.com