Machine vision integrates advanced imaging technology to enable real-time inspection and quality control, while Programmable Logic Controllers (PLCs) provide robust automation and control for manufacturing processes through programmable software. Machine vision systems enhance defect detection and product tracking with high precision, whereas PLCs ensure reliable operation of machinery by managing input-output signals and executing control algorithms. Explore the differences in capabilities and applications to optimize industrial automation solutions.

Why it is important

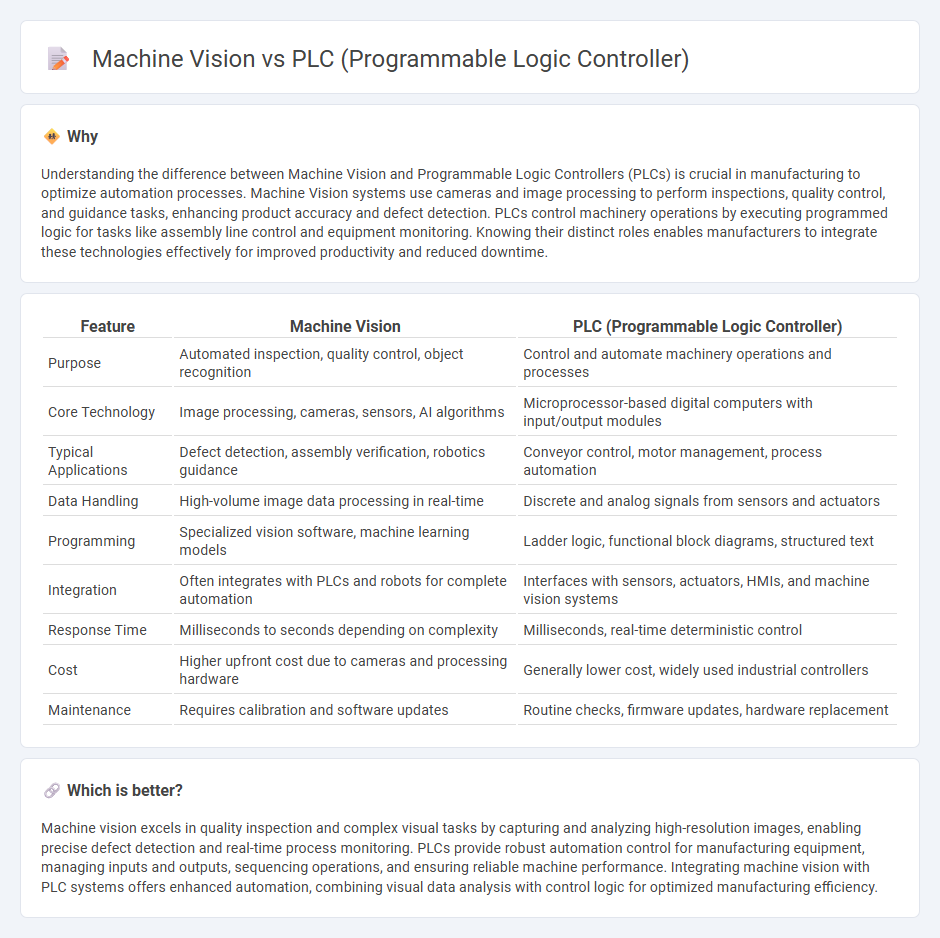

Understanding the difference between Machine Vision and Programmable Logic Controllers (PLCs) is crucial in manufacturing to optimize automation processes. Machine Vision systems use cameras and image processing to perform inspections, quality control, and guidance tasks, enhancing product accuracy and defect detection. PLCs control machinery operations by executing programmed logic for tasks like assembly line control and equipment monitoring. Knowing their distinct roles enables manufacturers to integrate these technologies effectively for improved productivity and reduced downtime.

Comparison Table

| Feature | Machine Vision | PLC (Programmable Logic Controller) |

|---|---|---|

| Purpose | Automated inspection, quality control, object recognition | Control and automate machinery operations and processes |

| Core Technology | Image processing, cameras, sensors, AI algorithms | Microprocessor-based digital computers with input/output modules |

| Typical Applications | Defect detection, assembly verification, robotics guidance | Conveyor control, motor management, process automation |

| Data Handling | High-volume image data processing in real-time | Discrete and analog signals from sensors and actuators |

| Programming | Specialized vision software, machine learning models | Ladder logic, functional block diagrams, structured text |

| Integration | Often integrates with PLCs and robots for complete automation | Interfaces with sensors, actuators, HMIs, and machine vision systems |

| Response Time | Milliseconds to seconds depending on complexity | Milliseconds, real-time deterministic control |

| Cost | Higher upfront cost due to cameras and processing hardware | Generally lower cost, widely used industrial controllers |

| Maintenance | Requires calibration and software updates | Routine checks, firmware updates, hardware replacement |

Which is better?

Machine vision excels in quality inspection and complex visual tasks by capturing and analyzing high-resolution images, enabling precise defect detection and real-time process monitoring. PLCs provide robust automation control for manufacturing equipment, managing inputs and outputs, sequencing operations, and ensuring reliable machine performance. Integrating machine vision with PLC systems offers enhanced automation, combining visual data analysis with control logic for optimized manufacturing efficiency.

Connection

Machine vision systems enhance automated manufacturing by providing real-time visual data to Programmable Logic Controllers (PLCs), enabling precise monitoring and control of production processes. PLCs interpret the visual inputs from cameras and sensors to execute commands that adjust machinery operations, ensuring quality control and reducing defects. This integration streamlines workflow efficiency, minimizes downtime, and supports Industry 4.0 smart factory initiatives through improved data-driven decision-making.

Key Terms

Automation control

Programmable Logic Controllers (PLCs) provide robust, real-time automation control by managing inputs and outputs through deterministic programming for industrial processes. Machine vision systems enhance automation by delivering high-precision image-based inspection, quality control, and guidance, but rely on PLCs for execution of control commands. Explore the integration of PLCs and machine vision to unlock advanced automation capabilities and optimize industrial performance.

Image processing

Programmable Logic Controllers (PLCs) primarily manage industrial automation through real-time control of machinery but lack the advanced image processing capabilities embedded in machine vision systems. Machine vision leverages high-resolution cameras and sophisticated algorithms to analyze visual data for quality inspection, defect detection, and robotic guidance, far surpassing PLCs in handling complex image analysis tasks. Discover how integrating machine vision with PLCs can revolutionize automation and boost efficiency.

Sensors

PLCs rely on traditional sensors such as proximity switches, photoelectric sensors, and temperature sensors to control and automate industrial processes, providing real-time data for precise machine operation. In contrast, machine vision systems use advanced image sensors and cameras to capture visual information, enabling complex inspection, measurement, and guidance tasks that go beyond simple binary input. Discover how integrating these sensor technologies can optimize automation and quality control in manufacturing environments.

Source and External Links

What is PLC ? Programmable Logic Controller - Unitronics - A PLC is a ruggedized computer used in industrial automation to control processes, machines, or production lines by receiving inputs from sensors and devices, processing data, and triggering outputs based on programmed logic.

What is a programmable logic controller (PLC)? - TechTarget - A PLC is a modular, solid-state computer customized to execute specific automated tasks, using input/output modules to connect with sensors, switches, and control devices, and is programmed using standardized industrial languages like Ladder Logic.

What Is a Programmable Logic Controller? | UTI - Designed for harsh industrial environments, a PLC reliably automates and controls machinery by monitoring sensors, making decisions based on pre-programmed instructions, and actuating outputs like motors, valves, or lights.

dowidth.com

dowidth.com