Soft robotics utilize flexible materials and biomimetic designs to enhance adaptability and safe human-machine interaction in manufacturing environments, contrasting with industrial exoskeletons that provide rigid mechanical support to augment worker strength and reduce fatigue during heavy-duty tasks. The integration of soft robotics improves precision in delicate assembly processes, while industrial exoskeletons focus on ergonomics and injury prevention for physically demanding operations. Explore further to understand how these technologies are revolutionizing manufacturing efficiency and safety.

Why it is important

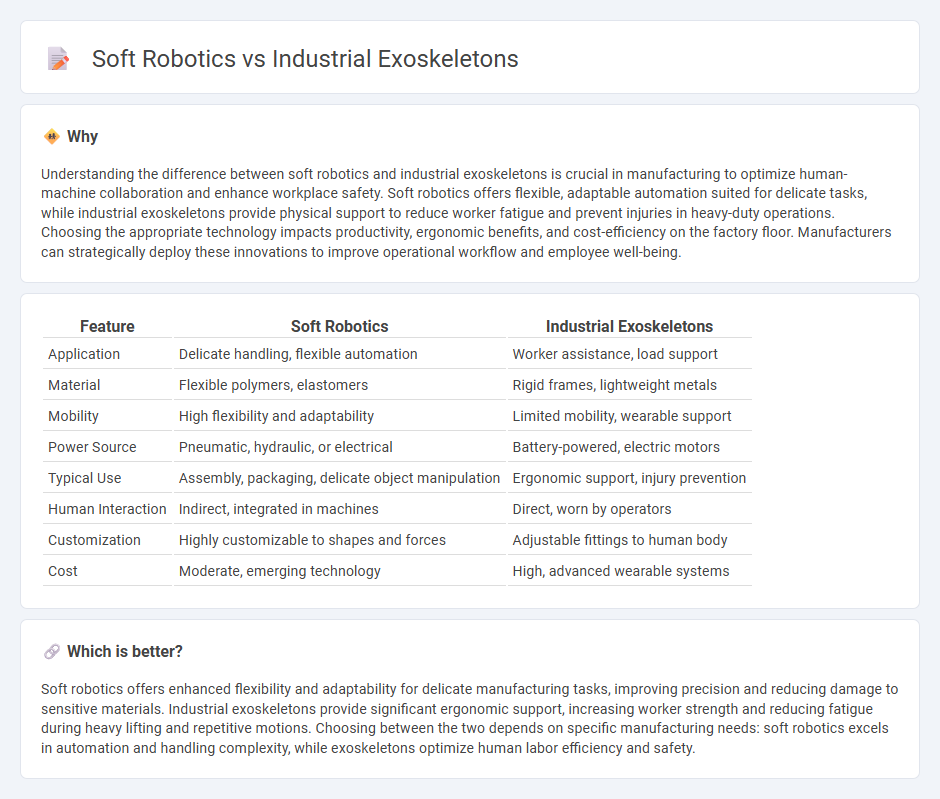

Understanding the difference between soft robotics and industrial exoskeletons is crucial in manufacturing to optimize human-machine collaboration and enhance workplace safety. Soft robotics offers flexible, adaptable automation suited for delicate tasks, while industrial exoskeletons provide physical support to reduce worker fatigue and prevent injuries in heavy-duty operations. Choosing the appropriate technology impacts productivity, ergonomic benefits, and cost-efficiency on the factory floor. Manufacturers can strategically deploy these innovations to improve operational workflow and employee well-being.

Comparison Table

| Feature | Soft Robotics | Industrial Exoskeletons |

|---|---|---|

| Application | Delicate handling, flexible automation | Worker assistance, load support |

| Material | Flexible polymers, elastomers | Rigid frames, lightweight metals |

| Mobility | High flexibility and adaptability | Limited mobility, wearable support |

| Power Source | Pneumatic, hydraulic, or electrical | Battery-powered, electric motors |

| Typical Use | Assembly, packaging, delicate object manipulation | Ergonomic support, injury prevention |

| Human Interaction | Indirect, integrated in machines | Direct, worn by operators |

| Customization | Highly customizable to shapes and forces | Adjustable fittings to human body |

| Cost | Moderate, emerging technology | High, advanced wearable systems |

Which is better?

Soft robotics offers enhanced flexibility and adaptability for delicate manufacturing tasks, improving precision and reducing damage to sensitive materials. Industrial exoskeletons provide significant ergonomic support, increasing worker strength and reducing fatigue during heavy lifting and repetitive motions. Choosing between the two depends on specific manufacturing needs: soft robotics excels in automation and handling complexity, while exoskeletons optimize human labor efficiency and safety.

Connection

Soft robotics and industrial exoskeletons are interconnected through their shared focus on enhancing human-machine collaboration in manufacturing environments. Soft robotics provides adaptable, compliant materials and actuators that improve the comfort and flexibility of industrial exoskeletons, enabling workers to perform repetitive or heavy tasks with reduced physical strain. This synergy boosts productivity, reduces workplace injuries, and advances ergonomic design in modern manufacturing processes.

Key Terms

Human Augmentation

Industrial exoskeletons enhance human strength and endurance by providing rigid structural support, enabling workers to lift heavy loads and reduce fatigue in manufacturing and construction environments. Soft robotics utilize flexible materials and adaptive controls to mimic natural muscle movement, offering increased comfort and improved dexterity for human augmentation applications. Explore the latest advancements in human augmentation technologies to discover which solution best fits your industry needs.

Wearable Technology

Industrial exoskeletons enhance worker strength and endurance by providing rigid support structures designed to reduce musculoskeletal strain in manufacturing and logistics environments. Soft robotics employs flexible, lightweight materials and actuators that conform to the body's movements, offering improved comfort and adaptability for prolonged wear in wearable technology applications. Discover how these innovations are transforming workplace ergonomics and safety in our detailed analysis.

Adaptive Materials

Adaptive materials in industrial exoskeletons provide enhanced strength, durability, and load-bearing capabilities, making them ideal for repetitive heavy-duty tasks in manufacturing and construction. Soft robotics leverage flexible, lightweight adaptive materials that mimic natural movements, offering superior comfort and dexterity for human-robot interaction in delicate assembly and rehabilitation contexts. Explore more about how adaptive materials are revolutionizing both fields and driving innovation in wearable robotics technology.

Source and External Links

What is an Industrial Exoskeleton? - Qviro Blog - Industrial exoskeletons are wearable tools that support workers in physically demanding tasks such as heavy lifting, repetitive movements, and awkward postures, reducing strain and injury risk while improving safety and productivity in industries like manufacturing, warehousing, and construction.

Industrial Exoskeletons - CDC Blogs - Industrial exoskeletons are designed to augment, amplify, or reinforce a worker's physical capabilities, primarily targeting the lower back and upper extremities, with manufacturers claiming benefits like reduced musculoskeletal injuries and increased productivity, though further research on effectiveness across sectors is still needed.

Reduce Job Injuries with EksoWorks Exoskeletons - Ekso Bionics - The Ekso EVO is a lightweight, upper-body exoskeleton designed for industrial workers to reduce fatigue and prevent injuries related to overhead work and repetitive lifting, aiming to boost both performance and safety in industrial environments.

dowidth.com

dowidth.com