Machine vision inspection utilizes high-resolution cameras and image processing algorithms to detect surface defects and assembly errors in manufacturing lines, enhancing quality control with real-time analysis. Acoustic emission testing captures transient elastic waves generated by material stress or cracks, providing early detection of internal faults in structural components without interrupting production. Explore how these advanced technologies improve precision and efficiency in manufacturing processes.

Why it is important

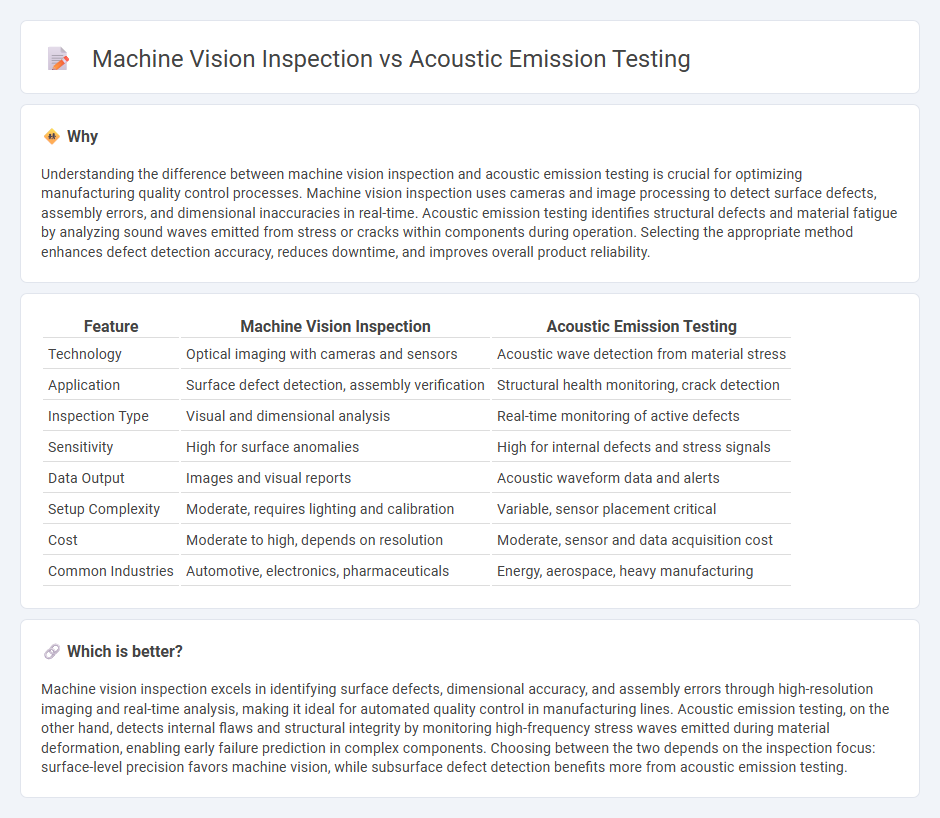

Understanding the difference between machine vision inspection and acoustic emission testing is crucial for optimizing manufacturing quality control processes. Machine vision inspection uses cameras and image processing to detect surface defects, assembly errors, and dimensional inaccuracies in real-time. Acoustic emission testing identifies structural defects and material fatigue by analyzing sound waves emitted from stress or cracks within components during operation. Selecting the appropriate method enhances defect detection accuracy, reduces downtime, and improves overall product reliability.

Comparison Table

| Feature | Machine Vision Inspection | Acoustic Emission Testing |

|---|---|---|

| Technology | Optical imaging with cameras and sensors | Acoustic wave detection from material stress |

| Application | Surface defect detection, assembly verification | Structural health monitoring, crack detection |

| Inspection Type | Visual and dimensional analysis | Real-time monitoring of active defects |

| Sensitivity | High for surface anomalies | High for internal defects and stress signals |

| Data Output | Images and visual reports | Acoustic waveform data and alerts |

| Setup Complexity | Moderate, requires lighting and calibration | Variable, sensor placement critical |

| Cost | Moderate to high, depends on resolution | Moderate, sensor and data acquisition cost |

| Common Industries | Automotive, electronics, pharmaceuticals | Energy, aerospace, heavy manufacturing |

Which is better?

Machine vision inspection excels in identifying surface defects, dimensional accuracy, and assembly errors through high-resolution imaging and real-time analysis, making it ideal for automated quality control in manufacturing lines. Acoustic emission testing, on the other hand, detects internal flaws and structural integrity by monitoring high-frequency stress waves emitted during material deformation, enabling early failure prediction in complex components. Choosing between the two depends on the inspection focus: surface-level precision favors machine vision, while subsurface defect detection benefits more from acoustic emission testing.

Connection

Machine vision inspection and acoustic emission testing are connected through their complementary roles in non-destructive evaluation within manufacturing processes. Machine vision systems use high-resolution cameras and image processing algorithms to detect surface defects and dimensional inaccuracies, while acoustic emission testing captures stress waves generated by material deformation or crack propagation. Integrating these technologies enhances real-time quality control, enabling early detection of both visible and subsurface defects to reduce waste and improve product reliability.

Key Terms

**Acoustic Emission Testing:**

Acoustic Emission Testing (AET) detects transient elastic waves generated by the rapid release of energy from localized sources within materials, enabling early identification of defects such as cracks, corrosion, and leaks in structures like pipelines, pressure vessels, and bridges. Unlike machine vision inspection, which relies on visual data and surface analysis, AET provides real-time monitoring of internal structural integrity without requiring direct access or surface preparation. Explore the advantages and applications of Acoustic Emission Testing to enhance your nondestructive testing strategy.

Stress Waves

Acoustic emission testing detects stress waves generated by material deformation or crack propagation, enabling early identification of structural flaws through real-time monitoring of emitted ultrasonic signals. Machine vision inspection relies on high-resolution cameras and image processing algorithms to visually detect surface defects but cannot capture subsurface stress wave activity. Explore how integrating acoustic emission testing with machine vision can enhance comprehensive structural health monitoring.

Piezoelectric Sensors

Piezoelectric sensors are integral to acoustic emission testing, capturing stress waves generated by material defects for real-time structural health monitoring. In contrast, machine vision inspection relies on optical imaging techniques and does not incorporate piezoelectric technology, making it ideal for surface defect identification and quality control. Explore the specific advantages of piezoelectric sensors in acoustic emission testing to enhance non-destructive evaluation strategies.

Source and External Links

Acoustic Emission Testing - Acuren - Acoustic Emission Testing uses sensors to capture high-frequency signals emitted by structural defects under stress, enabling early, noninvasive detection and location of cracks, corrosion, and other flaws without disrupting operations, making it a cost-effective method widely applied to vessels, piping, infrastructure, and structural health monitoring.

How does Acoustic Emission Testing work? | Guide to AET - Acoustic Emission Testing is a nondestructive technique where AE sensors detect high-frequency emissions generated by stressed materials; the emissions' timing and strength are analyzed and triangulated to locate defects such as cracks or corrosion during either loaded or in-service conditions.

Field Inspections Acoustic Emission (AE) - MISTRAS Group - AE testing listens to natural energy released by growing cracks or fiber breaks in materials under stress, allowing detection of active damage well before failure, distinguishing it from other NDT methods that introduce energy, and is used for inspection during structural proof tests and plant operations.

dowidth.com

dowidth.com