Industrial Internet integrates sensors, machines, and data analytics to enhance manufacturing processes through real-time connectivity and monitoring. Industrial AI leverages advanced machine learning algorithms to enable predictive maintenance, quality control, and autonomous decision-making in factories. Explore further to understand how these technologies revolutionize the future of manufacturing.

Why it is important

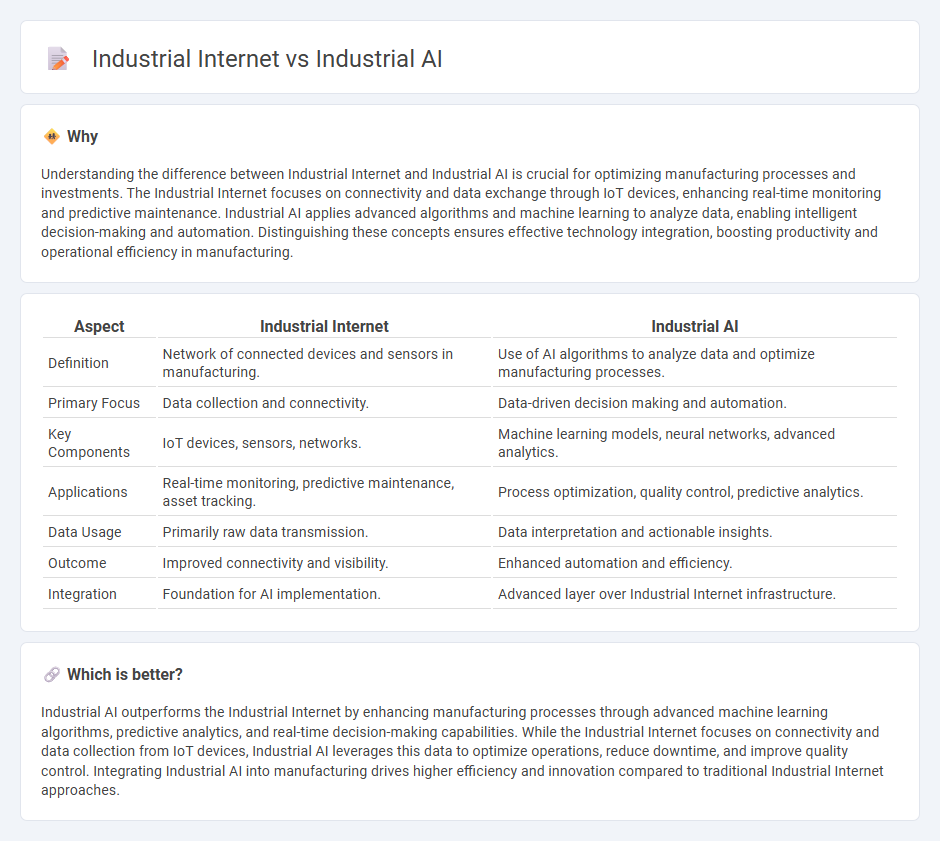

Understanding the difference between Industrial Internet and Industrial AI is crucial for optimizing manufacturing processes and investments. The Industrial Internet focuses on connectivity and data exchange through IoT devices, enhancing real-time monitoring and predictive maintenance. Industrial AI applies advanced algorithms and machine learning to analyze data, enabling intelligent decision-making and automation. Distinguishing these concepts ensures effective technology integration, boosting productivity and operational efficiency in manufacturing.

Comparison Table

| Aspect | Industrial Internet | Industrial AI |

|---|---|---|

| Definition | Network of connected devices and sensors in manufacturing. | Use of AI algorithms to analyze data and optimize manufacturing processes. |

| Primary Focus | Data collection and connectivity. | Data-driven decision making and automation. |

| Key Components | IoT devices, sensors, networks. | Machine learning models, neural networks, advanced analytics. |

| Applications | Real-time monitoring, predictive maintenance, asset tracking. | Process optimization, quality control, predictive analytics. |

| Data Usage | Primarily raw data transmission. | Data interpretation and actionable insights. |

| Outcome | Improved connectivity and visibility. | Enhanced automation and efficiency. |

| Integration | Foundation for AI implementation. | Advanced layer over Industrial Internet infrastructure. |

Which is better?

Industrial AI outperforms the Industrial Internet by enhancing manufacturing processes through advanced machine learning algorithms, predictive analytics, and real-time decision-making capabilities. While the Industrial Internet focuses on connectivity and data collection from IoT devices, Industrial AI leverages this data to optimize operations, reduce downtime, and improve quality control. Integrating Industrial AI into manufacturing drives higher efficiency and innovation compared to traditional Industrial Internet approaches.

Connection

The Industrial Internet integrates sensors, machines, and data analytics to optimize manufacturing processes, while Industrial AI leverages this data to enable predictive maintenance and smart automation. Together, they drive real-time decision-making and enhance operational efficiency in manufacturing environments. This synergy improves productivity, reduces downtime, and supports adaptive supply chain management.

Key Terms

Predictive Maintenance

Industrial AI leverages machine learning algorithms, big data analytics, and real-time sensor data to enhance predictive maintenance by accurately forecasting equipment failures and optimizing maintenance schedules. The industrial internet emphasizes connectivity and data exchange through IoT devices to monitor asset conditions and gather operational insights. Explore in-depth comparisons and best practices to harness the full potential of predictive maintenance in industrial settings.

Edge Computing

Industrial AI leverages advanced machine learning algorithms and real-time data analytics at the edge to optimize manufacturing processes, predictive maintenance, and quality control. In contrast, the Industrial Internet emphasizes connectivity and sensor networks, enabling vast data collection but often relying on centralized cloud processing. Explore how edge computing bridges these technologies to enhance operational efficiency and reduce latency in smart factories.

Data Integration

Industrial AI leverages advanced machine learning algorithms to process and analyze data from diverse industrial sources, enabling predictive maintenance and operational efficiency. The industrial internet focuses on connecting machines and devices through IoT networks to collect real-time data streams, emphasizing seamless device interoperability. Discover how data integration strategies differ between Industrial AI and the industrial internet to unlock transformative industrial insights.

Source and External Links

What is Industrial AI? - Industrial AI applies AI technologies such as physical AI, generative AI, and digital twins to automate, optimize, and enhance decision-making in industrial processes, driving efficiency, resilience, and digital transformation across manufacturing and logistics.

What is industrial AI? - Industrial AI focuses on automating and optimizing industrial operations--such as movement of goods, supply chain management, and predictive maintenance--using large, often complex datasets to enable real-time analytics, robotics, and zero-tolerance reliability in process manufacturing.

Industrial AI - Industrial AI delivers actionable, real-time insights via machine learning and advanced analytics, breaking down data silos to automate production, reduce risk, drive innovation, and support sustainability goals in industrial organizations.

dowidth.com

dowidth.com