Industrial metaverse integrates virtual reality, augmented reality, and digital twins to create immersive, interactive manufacturing environments. Cyber-Physical Systems (CPS) focus on the seamless integration of computation, networking, and physical processes for real-time monitoring and control in manufacturing. Explore more to understand how these technologies transform industrial production and operational efficiency.

Why it is important

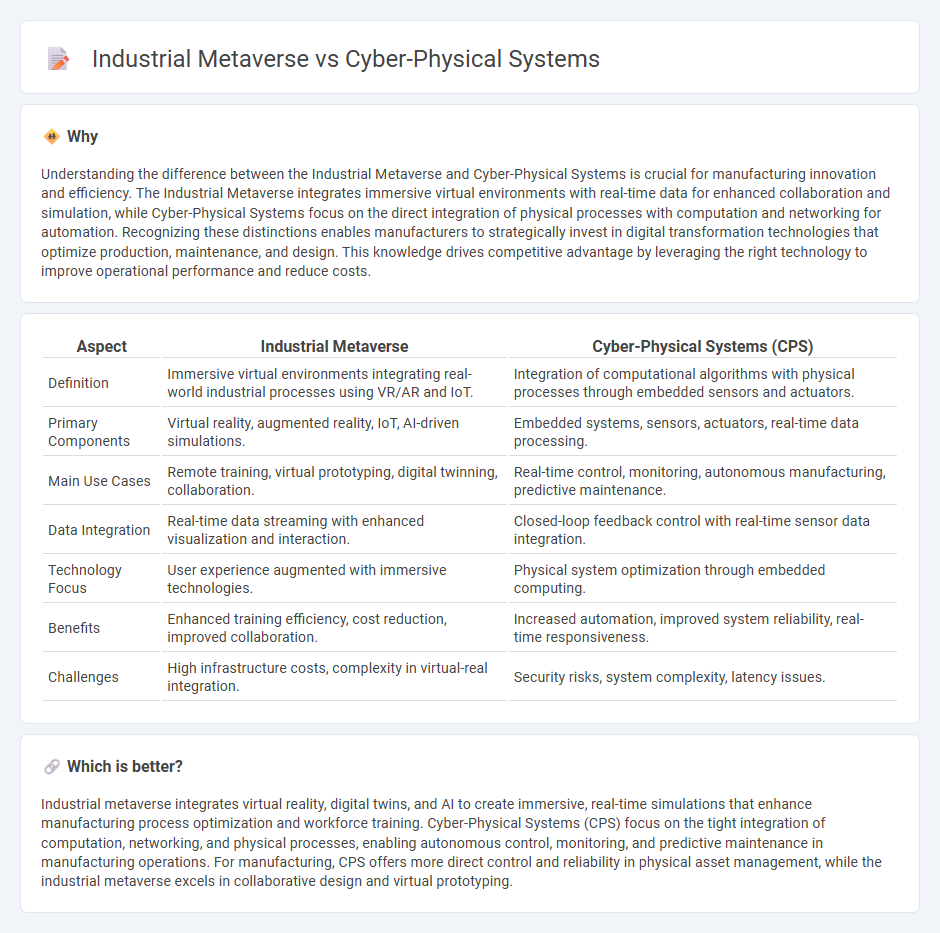

Understanding the difference between the Industrial Metaverse and Cyber-Physical Systems is crucial for manufacturing innovation and efficiency. The Industrial Metaverse integrates immersive virtual environments with real-time data for enhanced collaboration and simulation, while Cyber-Physical Systems focus on the direct integration of physical processes with computation and networking for automation. Recognizing these distinctions enables manufacturers to strategically invest in digital transformation technologies that optimize production, maintenance, and design. This knowledge drives competitive advantage by leveraging the right technology to improve operational performance and reduce costs.

Comparison Table

| Aspect | Industrial Metaverse | Cyber-Physical Systems (CPS) |

|---|---|---|

| Definition | Immersive virtual environments integrating real-world industrial processes using VR/AR and IoT. | Integration of computational algorithms with physical processes through embedded sensors and actuators. |

| Primary Components | Virtual reality, augmented reality, IoT, AI-driven simulations. | Embedded systems, sensors, actuators, real-time data processing. |

| Main Use Cases | Remote training, virtual prototyping, digital twinning, collaboration. | Real-time control, monitoring, autonomous manufacturing, predictive maintenance. |

| Data Integration | Real-time data streaming with enhanced visualization and interaction. | Closed-loop feedback control with real-time sensor data integration. |

| Technology Focus | User experience augmented with immersive technologies. | Physical system optimization through embedded computing. |

| Benefits | Enhanced training efficiency, cost reduction, improved collaboration. | Increased automation, improved system reliability, real-time responsiveness. |

| Challenges | High infrastructure costs, complexity in virtual-real integration. | Security risks, system complexity, latency issues. |

Which is better?

Industrial metaverse integrates virtual reality, digital twins, and AI to create immersive, real-time simulations that enhance manufacturing process optimization and workforce training. Cyber-Physical Systems (CPS) focus on the tight integration of computation, networking, and physical processes, enabling autonomous control, monitoring, and predictive maintenance in manufacturing operations. For manufacturing, CPS offers more direct control and reliability in physical asset management, while the industrial metaverse excels in collaborative design and virtual prototyping.

Connection

Industrial metaverse integrates immersive virtual environments with real-time data from Cyber-Physical Systems (CPS), enabling seamless synchronization between physical manufacturing processes and digital simulations. CPS utilizes sensors, actuators, and embedded computing to monitor and control machinery, facilitating predictive maintenance and process optimization within the industrial metaverse. This convergence drives enhanced productivity, real-time decision-making, and adaptive manufacturing strategies by bridging physical assets and virtual models.

Key Terms

Digital Twin

Cyber-Physical Systems (CPS) integrate physical processes with computational resources for real-time monitoring and control, forming the foundational framework for Digital Twin technology. Industrial metaverse expands upon this by creating immersive virtual environments that leverage Digital Twins for advanced simulation, collaboration, and optimization in manufacturing and industrial sectors. Explore the transformative impact of Digital Twins within Industrial metaverse and CPS ecosystems to unlock new opportunities in smart industry innovation.

Real-Time Data Integration

Cyber-Physical Systems (CPS) integrate real-time data from physical processes through embedded sensors and actuators enabling immediate control and feedback loops in industrial environments. The Industrial Metaverse leverages real-time data integration within immersive virtual spaces to simulate, optimize, and predict complex industrial operations, enhancing decision-making and collaboration. Explore the transformative impact of real-time data fusion in industrial innovation to understand how these technologies reshape manufacturing landscapes.

Virtual Simulation

Cyber-Physical Systems (CPS) integrate physical processes with computational algorithms to enable real-time monitoring and control, offering precise and adaptive virtual simulations for industrial applications. The Industrial Metaverse extends this concept by creating immersive virtual environments where digital twins of machinery and workflows facilitate collaborative design, training, and predictive maintenance on a broader scale. Explore the transformative potential of virtual simulation in these technologies to revolutionize manufacturing and operational efficiency.

Source and External Links

Cyber-Physical Systems (CPS) Explained - Describes cyber-physical systems as integrating physical and digital components to automate and control physical processes in a digital environment.

Cyber-Physical Systems - Discusses CPS as integrations of computation, networking, and physical processes with embedded computers and networks.

10 Examples of Cyber-Physical Systems - Highlights examples of CPS across various industries, such as manufacturing and healthcare, emphasizing their transformative potential.

dowidth.com

dowidth.com