Condition monitoring continuously tracks equipment parameters like vibration and temperature to identify abnormalities in real-time, enabling timely maintenance interventions. Predictive maintenance analyzes historical and current data using advanced algorithms to forecast potential failures before they occur, optimizing maintenance schedules and reducing unplanned downtime. Explore the differences in techniques and benefits to enhance your manufacturing efficiency.

Why it is important

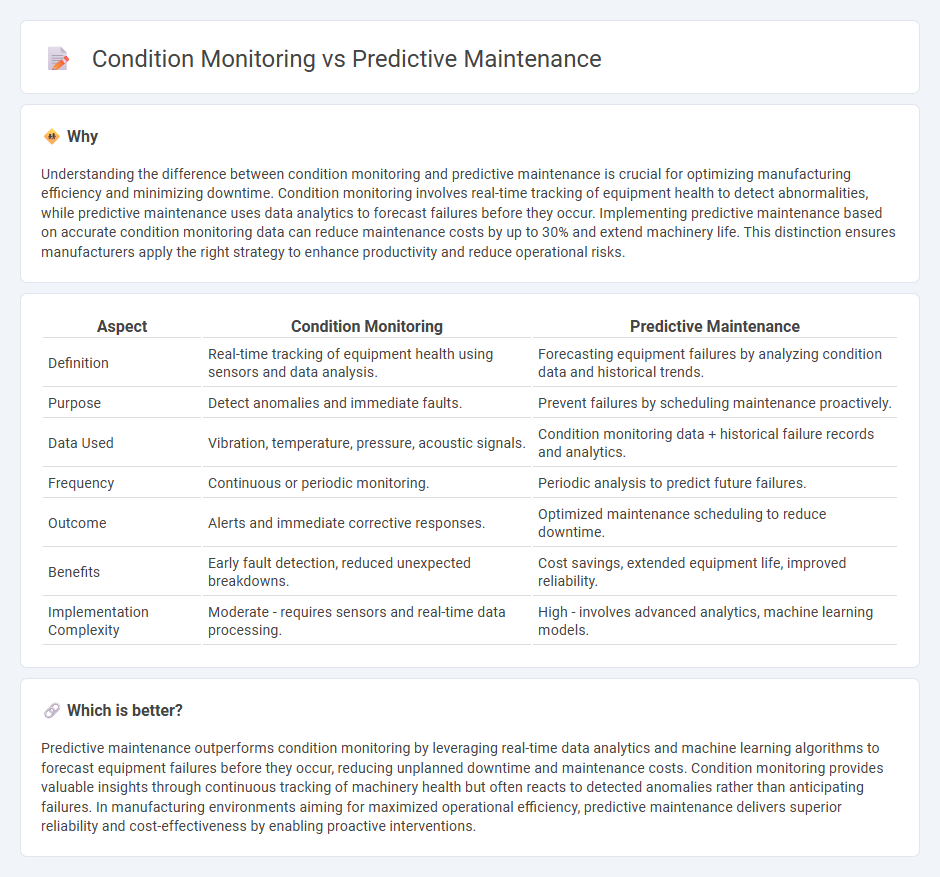

Understanding the difference between condition monitoring and predictive maintenance is crucial for optimizing manufacturing efficiency and minimizing downtime. Condition monitoring involves real-time tracking of equipment health to detect abnormalities, while predictive maintenance uses data analytics to forecast failures before they occur. Implementing predictive maintenance based on accurate condition monitoring data can reduce maintenance costs by up to 30% and extend machinery life. This distinction ensures manufacturers apply the right strategy to enhance productivity and reduce operational risks.

Comparison Table

| Aspect | Condition Monitoring | Predictive Maintenance |

|---|---|---|

| Definition | Real-time tracking of equipment health using sensors and data analysis. | Forecasting equipment failures by analyzing condition data and historical trends. |

| Purpose | Detect anomalies and immediate faults. | Prevent failures by scheduling maintenance proactively. |

| Data Used | Vibration, temperature, pressure, acoustic signals. | Condition monitoring data + historical failure records and analytics. |

| Frequency | Continuous or periodic monitoring. | Periodic analysis to predict future failures. |

| Outcome | Alerts and immediate corrective responses. | Optimized maintenance scheduling to reduce downtime. |

| Benefits | Early fault detection, reduced unexpected breakdowns. | Cost savings, extended equipment life, improved reliability. |

| Implementation Complexity | Moderate - requires sensors and real-time data processing. | High - involves advanced analytics, machine learning models. |

Which is better?

Predictive maintenance outperforms condition monitoring by leveraging real-time data analytics and machine learning algorithms to forecast equipment failures before they occur, reducing unplanned downtime and maintenance costs. Condition monitoring provides valuable insights through continuous tracking of machinery health but often reacts to detected anomalies rather than anticipating failures. In manufacturing environments aiming for maximized operational efficiency, predictive maintenance delivers superior reliability and cost-effectiveness by enabling proactive interventions.

Connection

Condition monitoring collects real-time data on equipment performance, enabling early detection of anomalies and degradation. Predictive maintenance utilizes this data through advanced analytics and machine learning to forecast potential failures and schedule timely interventions. Integrating condition monitoring with predictive maintenance minimizes unplanned downtime, reduces maintenance costs, and improves overall manufacturing efficiency.

Key Terms

Sensors

Predictive maintenance relies heavily on sensors that collect real-time data on equipment performance, such as vibration, temperature, and pressure sensors, to forecast potential failures before they occur. Condition monitoring uses similar sensors primarily to track the current state of machinery and detect anomalies or degradation during operation. Explore the latest advancements in sensor technology for predictive maintenance and condition monitoring to enhance efficiency and reduce downtime.

Data analytics

Predictive maintenance leverages advanced data analytics and machine learning algorithms to anticipate equipment failures before they occur, using historical and real-time sensor data to optimize maintenance schedules and reduce unplanned downtime. Condition monitoring continuously collects and analyzes operational parameters such as vibration, temperature, and pressure to detect anomalies and assess the current health of machinery, enabling immediate corrective actions. Explore detailed insights on integrating data analytics in predictive maintenance and condition monitoring to enhance asset reliability and operational efficiency.

Failure prediction

Predictive maintenance leverages advanced data analytics and machine learning algorithms to forecast equipment failure before it occurs, whereas condition monitoring primarily involves real-time tracking of asset health parameters like vibration, temperature, and pressure. Failure prediction within predictive maintenance minimizes unplanned downtime by anticipating faults based on historical trends and sensor data patterns. Explore how integrating predictive failure analysis can revolutionize your maintenance strategy and reduce operational costs.

Source and External Links

What is Predictive Maintenance? - IBM - Predictive maintenance uses real-time sensor data and machine learning to anticipate equipment failures, optimizing maintenance schedules and reducing unnecessary downtime.

Predictive maintenance - Wikipedia - Predictive maintenance estimates when maintenance is needed based on the actual condition of equipment, enabling cost savings and fewer unexpected failures compared to routine or preventive maintenance.

What is Predictive Maintenance? Benefits, Challenges & Examples - Predictive maintenance analyzes data patterns to forecast potential failures, allowing timely repairs, lower maintenance costs, and improved fleet efficiency and safety.

dowidth.com

dowidth.com