Collaborative robots (cobots) enhance manufacturing efficiency by working safely alongside human operators, offering flexibility and precision in tasks like assembly and packaging. Automated palletizers focus on high-speed, repetitive load stacking, optimizing throughput and reducing manual labor in warehousing and distribution centers. Explore the benefits and applications of collaborative robots versus automated palletizers to determine the ideal solution for your manufacturing needs.

Why it is important

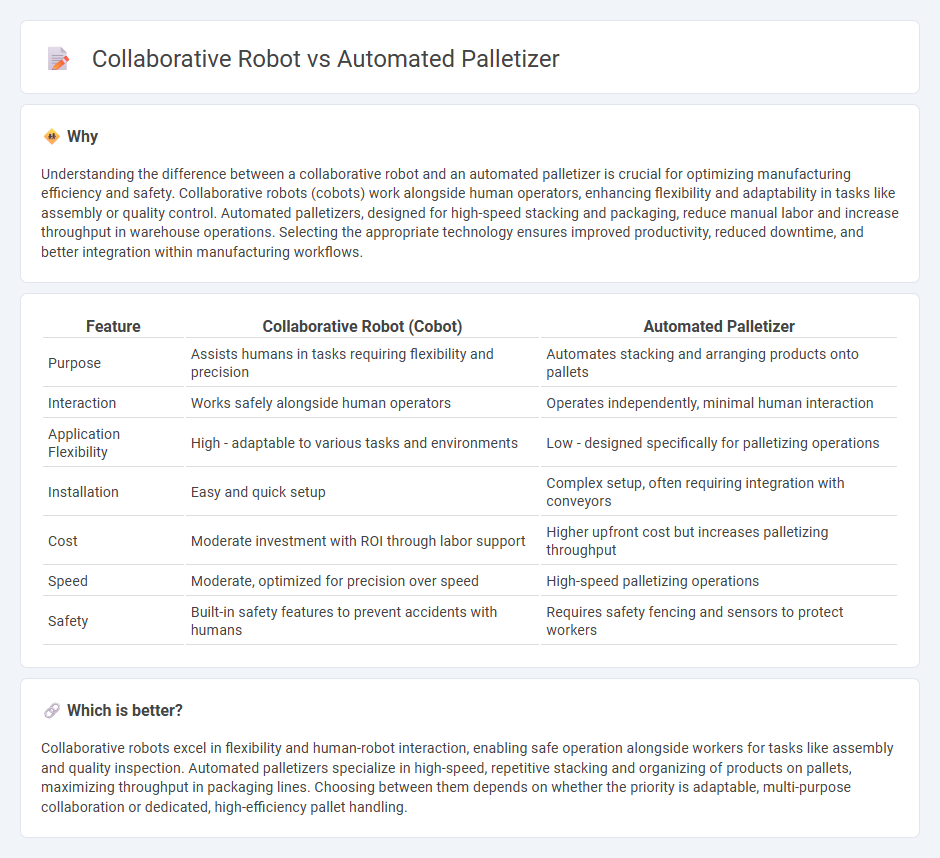

Understanding the difference between a collaborative robot and an automated palletizer is crucial for optimizing manufacturing efficiency and safety. Collaborative robots (cobots) work alongside human operators, enhancing flexibility and adaptability in tasks like assembly or quality control. Automated palletizers, designed for high-speed stacking and packaging, reduce manual labor and increase throughput in warehouse operations. Selecting the appropriate technology ensures improved productivity, reduced downtime, and better integration within manufacturing workflows.

Comparison Table

| Feature | Collaborative Robot (Cobot) | Automated Palletizer |

|---|---|---|

| Purpose | Assists humans in tasks requiring flexibility and precision | Automates stacking and arranging products onto pallets |

| Interaction | Works safely alongside human operators | Operates independently, minimal human interaction |

| Application Flexibility | High - adaptable to various tasks and environments | Low - designed specifically for palletizing operations |

| Installation | Easy and quick setup | Complex setup, often requiring integration with conveyors |

| Cost | Moderate investment with ROI through labor support | Higher upfront cost but increases palletizing throughput |

| Speed | Moderate, optimized for precision over speed | High-speed palletizing operations |

| Safety | Built-in safety features to prevent accidents with humans | Requires safety fencing and sensors to protect workers |

Which is better?

Collaborative robots excel in flexibility and human-robot interaction, enabling safe operation alongside workers for tasks like assembly and quality inspection. Automated palletizers specialize in high-speed, repetitive stacking and organizing of products on pallets, maximizing throughput in packaging lines. Choosing between them depends on whether the priority is adaptable, multi-purpose collaboration or dedicated, high-efficiency pallet handling.

Connection

Collaborative robots enhance manufacturing efficiency by working alongside human operators to handle complex or delicate tasks, seamlessly integrating with automated palletizers that organize and stack products for shipment. This synergy reduces labor costs, minimizes errors, and increases throughput on production lines. Data-driven coordination between collaborative robots and automated palletizers optimizes workflow and ensures consistent output quality.

Key Terms

End-of-Arm Tooling (EOAT)

Automated palletizers excel in high-speed, repetitive stacking tasks using specialized EOAT designed for precise, consistent gripping of uniform loads. Collaborative robots employ versatile EOAT capable of adapting to varied pallet patterns and safety requirements for human-robot interaction. Discover how EOAT innovation drives efficiency and flexibility in both automated and collaborative palletizing solutions.

Safety Systems

Automated palletizers leverage advanced safety systems such as light curtains, interlocked guards, and emergency stop mechanisms to ensure operator protection in high-speed material handling environments. Collaborative robots incorporate force sensors and compliance features that enable safe human-robot interaction without traditional physical barriers, meeting ISO/TS 15066 safety standards. Explore detailed comparisons of these safety technologies to optimize workplace safety in automation.

Throughput Rate

Automated palletizers typically achieve higher throughput rates with speeds reaching up to 1000 cycles per hour, optimized for continuous, high-volume palletizing in industrial settings. Collaborative robots (cobots) offer more flexibility and safer interaction with human workers but generally operate at slower speeds, averaging 250-500 cycles per hour, suitable for small to medium batch sizes. Explore detailed comparisons to determine which solution best aligns with your throughput requirements and operational goals.

Source and External Links

Robotic Palletizers and Palletizing Equipment - Automated palletizing uses robotic arms to pick and place products on pallets using pre-programmed stacking patterns, enabling fast, accurate, and efficient handling of large volumes while integrating advanced sensors and machine vision for real-time adjustments and high reliability.

Automated Palletizing: How It Works and How To Do It - Robotic palletizers operate by detecting items on conveyors, picking them up with specialized end effectors, and placing them precisely on pallets in programmed patterns to build stable layers until full pallets are formed, improving efficiency, safety, and flexibility.

ACPaQ Robotic Mixed Case Palletizer - Picking Solutions - Swisslog's ACPaQ is a data-driven robotic system designed for fast, reliable, and scalable mixed case palletizing that builds stable, store-friendly pallets by integrating conveyor technologies with KUKA robots to optimize order picking.

dowidth.com

dowidth.com