Collaborative robots, or cobots, are designed to work safely alongside human operators, offering flexibility and precision in assembly and quality control tasks, whereas pick-and-place robots specialize in high-speed repetitive material handling and sorting operations. Cobots incorporate advanced sensors and machine learning to adapt to dynamic environments, while pick-and-place robots excel in minimizing cycle times and maximizing throughput in manufacturing lines. Explore the strengths and applications of both robot types to optimize your production efficiency.

Why it is important

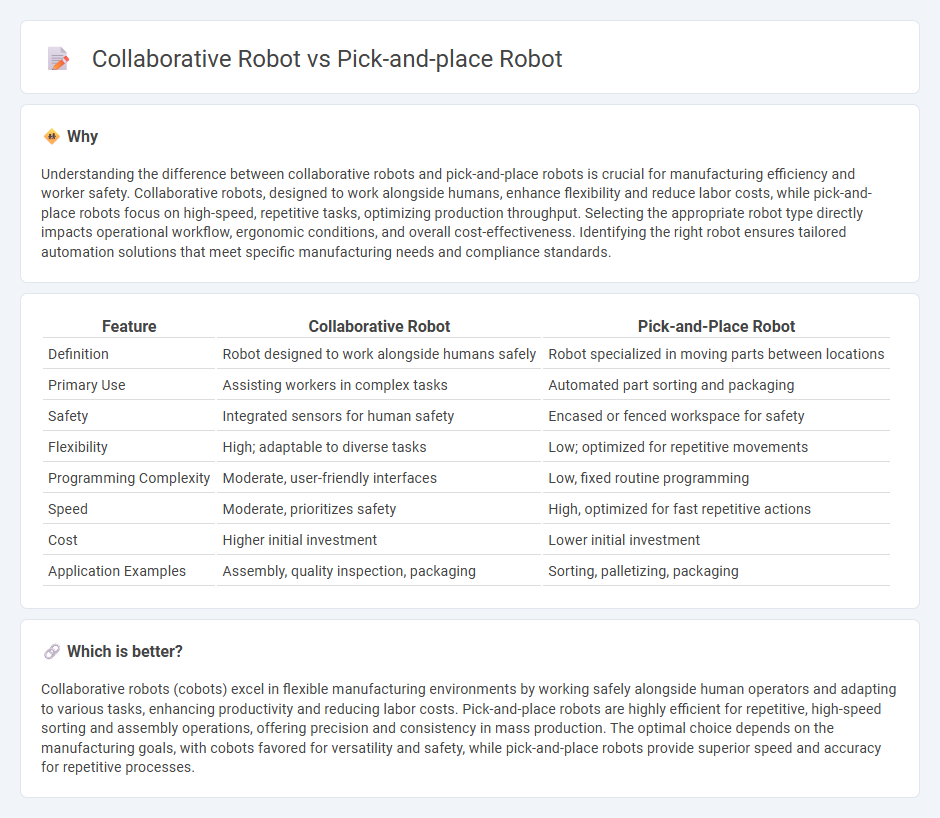

Understanding the difference between collaborative robots and pick-and-place robots is crucial for manufacturing efficiency and worker safety. Collaborative robots, designed to work alongside humans, enhance flexibility and reduce labor costs, while pick-and-place robots focus on high-speed, repetitive tasks, optimizing production throughput. Selecting the appropriate robot type directly impacts operational workflow, ergonomic conditions, and overall cost-effectiveness. Identifying the right robot ensures tailored automation solutions that meet specific manufacturing needs and compliance standards.

Comparison Table

| Feature | Collaborative Robot | Pick-and-Place Robot |

|---|---|---|

| Definition | Robot designed to work alongside humans safely | Robot specialized in moving parts between locations |

| Primary Use | Assisting workers in complex tasks | Automated part sorting and packaging |

| Safety | Integrated sensors for human safety | Encased or fenced workspace for safety |

| Flexibility | High; adaptable to diverse tasks | Low; optimized for repetitive movements |

| Programming Complexity | Moderate, user-friendly interfaces | Low, fixed routine programming |

| Speed | Moderate, prioritizes safety | High, optimized for fast repetitive actions |

| Cost | Higher initial investment | Lower initial investment |

| Application Examples | Assembly, quality inspection, packaging | Sorting, palletizing, packaging |

Which is better?

Collaborative robots (cobots) excel in flexible manufacturing environments by working safely alongside human operators and adapting to various tasks, enhancing productivity and reducing labor costs. Pick-and-place robots are highly efficient for repetitive, high-speed sorting and assembly operations, offering precision and consistency in mass production. The optimal choice depends on the manufacturing goals, with cobots favored for versatility and safety, while pick-and-place robots provide superior speed and accuracy for repetitive processes.

Connection

Collaborative robots (cobots) and pick-and-place robots intersect in automated manufacturing environments to enhance productivity and precision. Cobots often integrate pick-and-place functionalities, allowing them to work safely alongside human operators while efficiently handling repetitive tasks such as assembly, packaging, and sorting. This synergy optimizes workflow by combining the flexibility of collaborative robots with the speed and accuracy of pick-and-place systems.

Key Terms

Automation

Pick-and-place robots excel in high-speed, repetitive automation tasks primarily in manufacturing and packaging, offering precision and efficiency in material handling. Collaborative robots, or cobots, enhance automation flexibility by working safely alongside humans, adapting to varied production needs with integrated sensors and intuitive controls. Explore further to understand how these robotic solutions transform automation strategies across industries.

Safety

Pick-and-place robots operate in isolated environments to mitigate safety risks due to their high-speed, repetitive motions, while collaborative robots (cobots) integrate advanced sensors and force-limited designs to enable safe interaction with human workers. Safety standards like ISO 10218 and ISO/TS 15066 guide the deployment of these robots, emphasizing risk assessment and compliance in industrial settings. Discover how safety innovations in robotics enhance productivity and worker protection.

Human-robot interaction

Pick-and-place robots are typically designed for repetitive, high-speed tasks with minimal human interaction, operating in isolated environments to maximize efficiency and safety. Collaborative robots (cobots) emphasize safe, direct human-robot interaction, featuring advanced sensors and adaptive control systems that allow them to work alongside humans seamlessly. Explore how different human-robot interaction models shape automation strategies and workplace safety.

Source and External Links

What is a Pick and Place Robot? Uses and Types - Pick-and-place robots automate repetitive tasks by using advanced vision systems to identify, grasp, and move objects between locations, greatly increasing manufacturing production rates.

What is a Pick and Place Robot and How Does it Work? - PWR Pack - Different types of pick-and-place robots include Cartesian, fast pick, robotic arms, delta, and collaborative robots, each specialized for varying speed, precision, and collaborative tasks.

Pick and Place Robots: An In-Depth Guide to Their Functionality and Applications - Cartesian pick-and-place robots operate in three linear axes with high precision and reliability, widely used in industries requiring exact positioning such as electronics and pharmaceuticals.

dowidth.com

dowidth.com